صب قوة الاختناق للشاحن على متن الطائرة

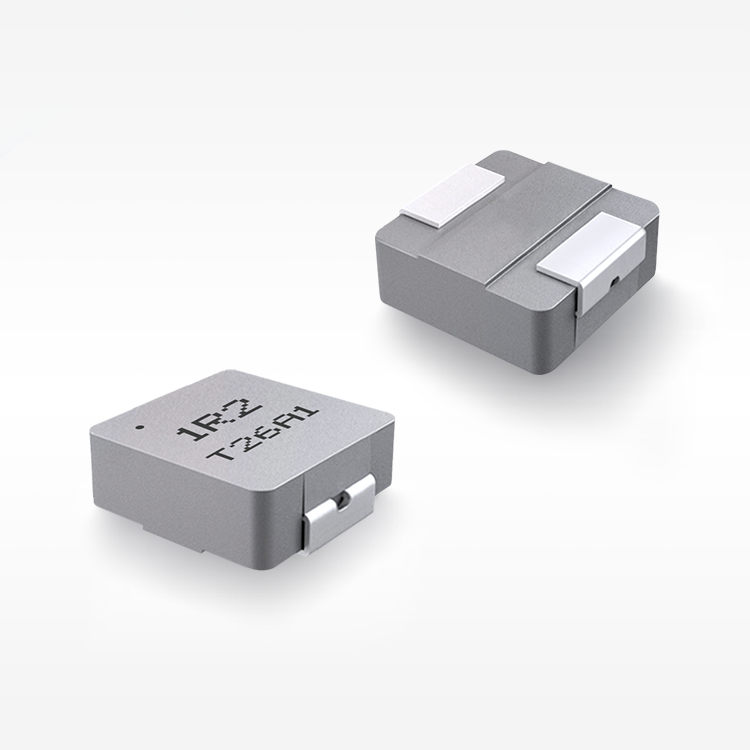

يمثل مثبّت الطاقة المصهور للشاحن المحمول عنصرًا حيويًا في أنظمة شحن المركبات الكهربائية الحديثة، ويُصمم لتنظيم تدفق التيار والحفاظ على توصيل طاقة مستقر أثناء عملية الشحن. يعمل هذا المحث المتخصص كمرشح كهرومغناطيسي يُسهم في تسوية تيارات التموج وانقطاعات الجهد، ويضمن نقل طاقة ثابتة من شبكة الكهرباء إلى حزمة بطارية المركبة. يتضمن مثبّت الطاقة المصهور للشاحن المدمج مواد قلب مغناطيسية متقدمة وموصلات نحاسية ملفوفة بدقة، ومغلّفة داخل هيكل مصبوب متين يوفر إدارة حرارية ممتازة وحماية بيئية. تتضمن الوظيفة الأساسية لهذا المكون تخزين الطاقة المغناطيسية مؤقتًا وإطلاقها بطريقة مضبوطة، مما يقلل بشكل فعّال من التداخل الكهرومغناطيسي مع الحفاظ على كفاءة شحن مثلى. وتشمل الميزات التقنية القدرة على التشغيل بتردد عالٍ، وانخفاض الفقد في القلب المغناطيسي، وتوصيل حراري متفوق يتيح أداءً موثوقًا عبر ظروف درجات حرارة مختلفة. يستخدم مثبّت الطاقة المصهور للشاحن المدمج قلوب من الفيريت أو مسحوق الحديد التي تتميز بامتصاص مغناطيسي استثنائي وفقد هستيري ضئيل، مما يساهم في كفاءة النظام بشكل عام. تضمن عمليات التصنيع المتقدمة تحكمًا دقيقًا في التسامحات وخصائص كهربائية متسقة عبر دفعات الإنتاج. ويوفر التصميم المصهور ثباتًا ميكانيكيًا وحماية ضد الرطوبة والغبار والاهتزاز، ما يجعله مناسبًا للتطبيقات المرورية حيث تكون الموثوقية أمرًا بالغ الأهمية. وتمتد التطبيقات عبر منصات متنوعة من المركبات الكهربائية، بما في ذلك المركبات الكهربائية بالكامل (BEV)، والمركبات الهجينة القابلة للشحن (PHEV)، وأنظمة النقل الكهربائية التجارية. ويمكن دمج مثبّت الطاقة المصهور للشاحن المدمج بسلاسة مع دوائر تصحيح معامل القدرة، ومحولات التيار المستمر إلى التيار المستمر (DC-DC)، وأنظمة إدارة البطاريات لتحسين أداء الشحن. كما تتيح مرونة التركيب تكوينات تركيب على السطح (SMD) أو عبر الثقوب (THT)، لتتناسب مع تخطيطات مختلفة للوحة الدوائر المطبوعة (PCB) ومع قيود المساحة. وتشمل بروتوكولات ضمان الجودة اختبارات صارمة للأداء الكهربائي، والدورات الحرارية، والمتانة البيئية لتلبية معايير ولوائح صناعة السيارات.