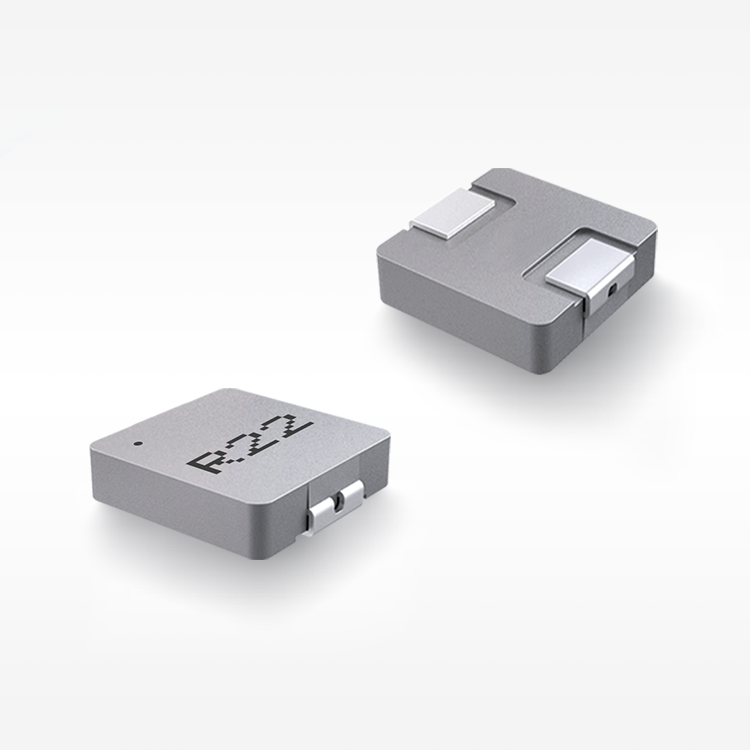

שניצר עיבוי סליל כוח פריט

השסתום החשמלי עם ליבת פריט מייצג רכיב אלקטרומגנטי מתקדם שתוכנן לשלוט בזרימת זרם ולức הרעש במעגלים אלקטרוניים שונים. רכיב אינדוקטיבי מתקדם זה משתמש בחומר פריטי כבליבת המגנט, אשר לאחר מכן מכוסה בתהליך ייצור מדויק ליצירת פתרון עמיד ואמין לניהול הספק. השסתום החשמלי עם ליבת פריט ממולאת משרת מספר פונקציות חשובות במערכות אלקטרוניות, כולל איחסון אנרגיה, חלקות זרם,авיתור הפרעות אלקטרומגנטיות ורגולציה של מתח ביישומים שונים. היסודות הטכנולוגיים של השסתום החשמלי עם ליבת פריט ממולאת מונחים בבנייתו הייחודית. חומר הפריט, שעשוי מאוקסיד ברזל בשילוב עם יסודות מתכתיים אחרים, מספק חדירות מגנטית יוצאת דופן תוך שמירה על מוליכות חשמלית נמוכה. שילוב זה מאפשר לרכיב לאגור אנרגיה מגנטית בצורה יעילה תוך מזעור של איבדי זרמי עיבוש העלולים לפגוע בביצועים. תהליך המילוי עוטף את ליבת הפריט והכריכות הנחושתית בתיבה מגנה, ומייצר סביבה חסומה המגנה על הרכיבים הפנימיים מגורמים סביבתיים כגון רטיבות, אבק ותנודות טמפרטורה. תכונות טכנולוגיות עיקריות של השסתום החשמלי עם ליבת פריט ממולאת כוללות צפיפות שטף רוויה גבוהה, יציבות תרמית מצוינת ומאפייני תגובה תדר יוצאי דופן. חומר ליבת הפריט מציג תכונות מגנטיות מרשימות על פני טווח רחב של תדרים, מה שהופך אותו ליעיל במיוחד ביישומי ספק כוח מתחלף. טכניקת המילוי מבטיחה בקרת ממדים מדויקת ופרמטרים חשמליים עקביים, ומאפשרת לייצר רכיבים עם דרישות סובלנות צמודות. היישומים של השסתום החשמלי עם ליבת פריט ממולאת משתרעים על פני תעשיות רבות ומערכות אלקטרוניות. רכיבים אלו משמשים בצורה נרחבת בספקי כוח מתחלפים, ממירי DC-DC, נהגי מנוע, אלקטרוניות רכב, ציוד תקשורת ומערכות אנרגיה מתחדשת. במעגלי ספק כוח, השסתום החשמלי עם ליבת פריט ממולאת משמש להחלקת זרם הריפל ולחיזוק הפלטת אלקטרומגנטית. יישומי רכב נהנים מהיכולת של הרכיב לעמוד בתנאי סביבה קיצוניים תוך שמירה על ביצועים יציבים גם בטווחי טמפרטורה קיצוניים.