אינדוקטורים מגן כוח עם זרם גבוה

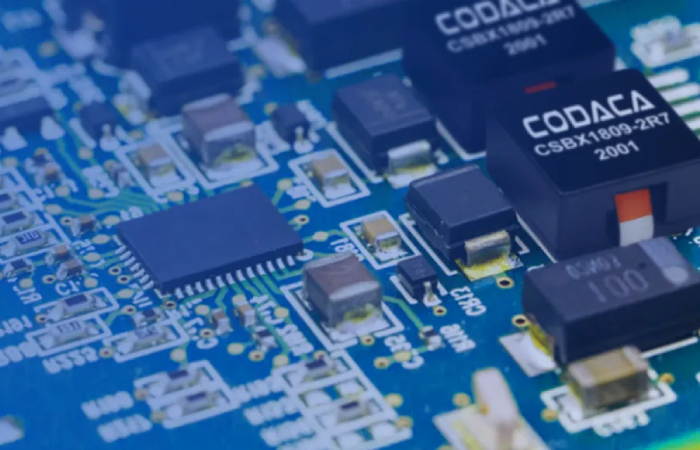

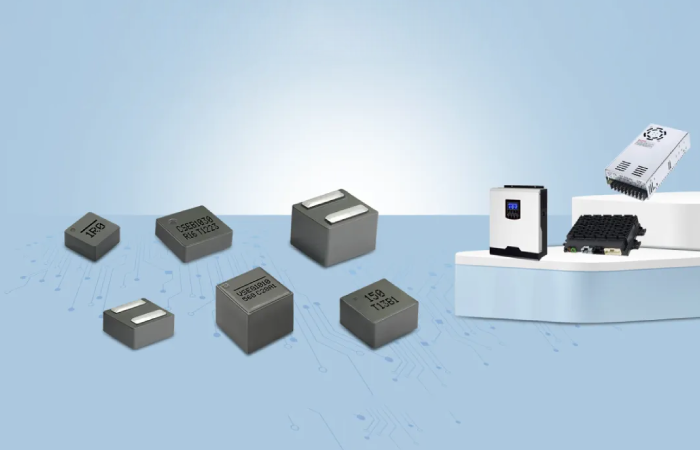

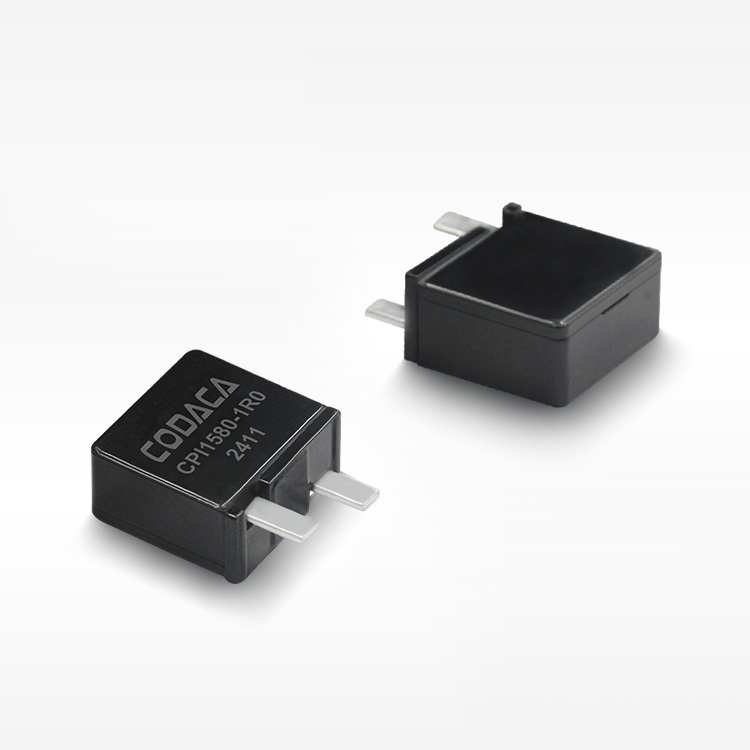

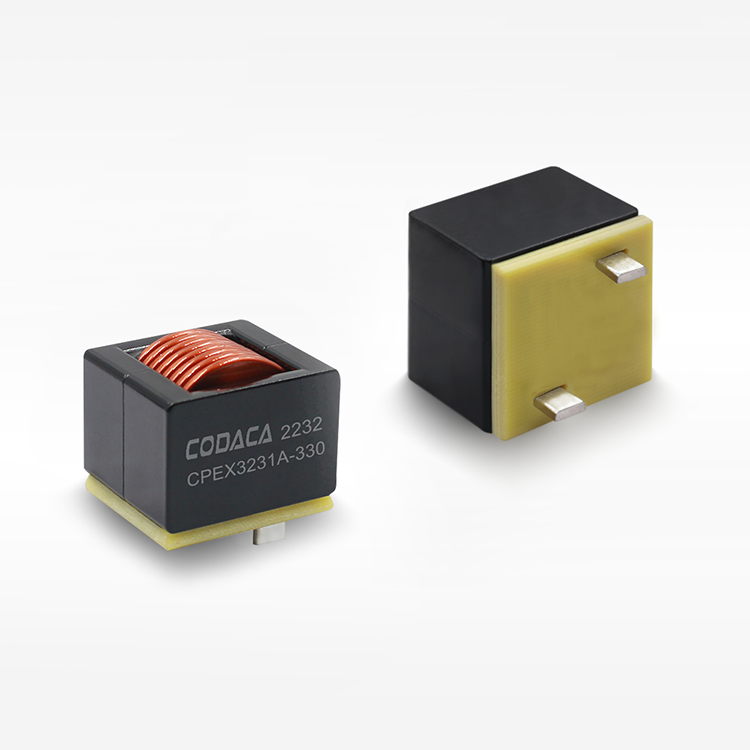

מנדקים חשמל מגוננים עם זרם גבוה הם רכיבים מיוחדים שנועדו לנהל ולאחסן אנרגיה בתוך מעגלים אלקטרוניים. מנעים אלה משמשים תפקיד קריטי בתהליך סינון ושידוך של יציאת זרם ישיר במקורות חשמל, תוך מתן שלמות אות ביישומים בתדר גבוה. טכנולוגית מתקדמת, הם מתגאים בעיצוב קומפקטי שמקטין את המרחב ומאפשר פיזור חום יעיל. הליבה עשויה בדרך כלל מחומרים המפחיתים הפרעות מגנטיות, והמעצבת מכסה את התגלילה כדי למנוע הפרעות אלקטרומגנטיות. תכונות אלה הופכות אותם לחסרי ערך במגוון של אלקטרוניקה כוח, כולל אספקת חשמל בתנועה מחוברת, רגולטורים מתח, ומערכות אנרגיה מתחדשת, שבו הם מבטיחים את הפעלה האמינה של המכשירים אפילו בסביבות חשמליות קשות.

קבל תקציב