שילוב של עיצוב קומפקטי ויעילות בייצור

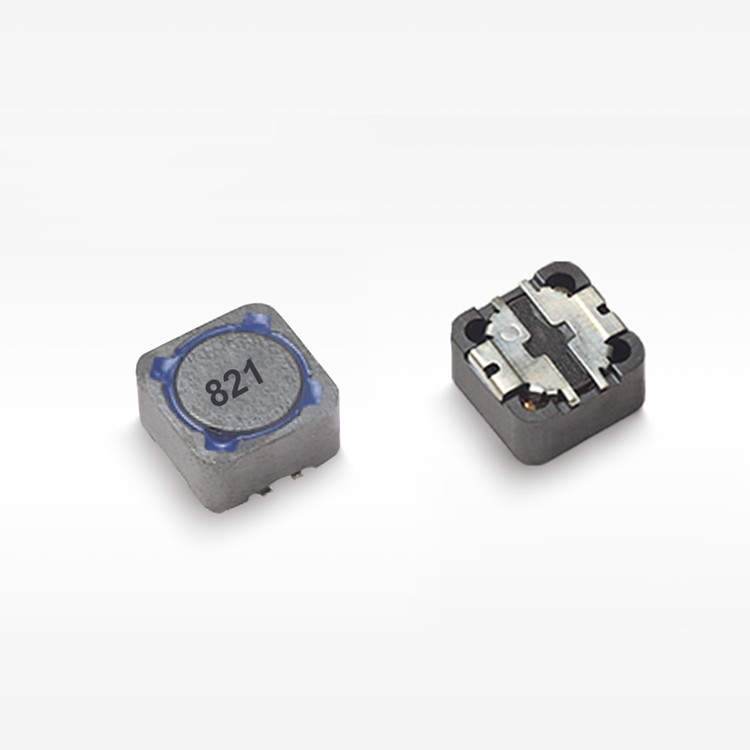

הסליל החשמלי המודל SMD מייצג קפיצת מדרגה בהקטנת רכיבים ואופטימיזציה של ייצור, ומציע ביצועים יוצאי דופן בצורות-מיקרו קומפקטיות במיוחד שמתאימות לדרישות הקפדניות של מערכות אלקטרוניות מודרניות. העיצוב לשילוב על פני לוח (surface-mount) מאפשר תהליכי ייצור אוטומטיים לגמרי, המצמצמים משמעותית את עלויות הייצור תוך שיפור דיוק ועקביות בהתקנה, ביחס לחלופות עם מחטבים. התאימות לאוטומציה מאפשרת לייצרנים להשיג תפוקת ייצור גבוהה יותר עם עלויות עבודה מופחתות ושיפור בקרת איכות, מה שהופך את הסליל החשמלי המודל SMD לפתרון כלכלי ומושך ביישומים בנפח גבוה. הבנייה הנמוכה של רכיבים אלו פותרת אילוצים קריטיים של שטח במכשירים ניידים, מערכות משובצות ועוד יישומים בהם שטח הלוח הוא בשער גבוה. הסליל החשמלי המודל SMD תופס בדרך כלל 50%-70% פחות שטח לוח בהשוואה לרכיבים שקולים מסוג מחטבים, ומאפשר לעורכי פרויקט להוסיף יכולות נוספות או לצמצם את גודל המערכת הכוללת מבלי להקריב ביצועים. אפשרויות הרגל"ד התקניות מבטיחות תאימות לספריות עיצוב קיימות ולציוד ייצור, ומשפשטות את המעבר מרכיבים ישנים ומצמצמות את זמן הפיתוח. הבנייה המודלת מספקת יציבות מכנית מצוינת בתהליכי ייצור, עמידה במתחים תרמיים הקשורים ללحام ריפלו בלי שינוי בהשראות או נזק פיזי. עמידות זו מונעת את הצורך בהליכים מיוחדים לטיפול או מנגנוני אבטחה נוספים, ועוזרת לזרז תהליכי ייצור. סובלנות הממדים העקבית, שנשגת באמצעות טכניקות מיפוי מדויקות, מבטיחה התקנה אמינה על ידי ציוד איסוף והצבה, מצמצמת פגמים בהרכבה ומשפרת תשומות ייצור. הסליל החשמלי המודל SMD תומך באפשרויות אריזה שונות, כולל פורמטים של סרט וגליל המותאמים במיוחד לשורות ייצור אוטומטיות במהירות גבוהה, ומאפשרים לייצרנים לשמור על מחזורי ייצור מהירים תוך הבטחת זמינות ו איכות הרכיב.