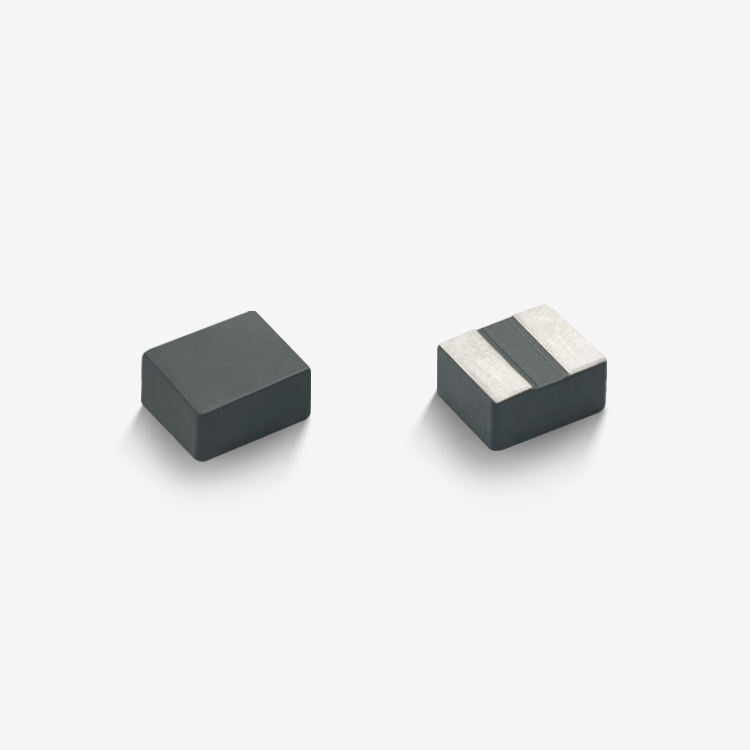

Aperta Technologia Munitionis Magneticæ

Praecipuum commodum inductoris muniti alti frequentiae inest in sua artificiosa technologia munitio magnetica quae electromagneticam compatibilitatem in modernis systematibus electronicis revolvit. Haec innovativa munitio adhibet diligenter selecta materia ferromagnetica quae fluxus magneticos intra structuram componentis continere et dirigere parata sunt, effugium campi electromagnetici praestans quod tradidionaliter intermissiones in densus schematibus circuituum causat. Effectus munitiois ad magnitudines laudabiles pervenit, plerumque plus quam 40 decibella suppressionis intermissionis electromagneticae in criticis frequentiarum intervallis praebens. Haec praestans capacitas continendi ex structura munitii multistratata oritur quae et materiales nucleares alti permeabilitatis et externa elementa examinandi magnetici complectitur, quae coniunctim operantur ut barriera electromagnetica completa creetur. Consequentiis huius technologiae longius patet quam simplex intermissio minuenda, permittit designatoribus circuituum componentes sensibilis propius collocare absque integritate signi compromittenda vel effectibus coniunctionis indesideratis inducendis. Processus manufacturandi constantiam munitii per technicas depositionis materiae et coniunctionis praecisione regulatas certificant, quae proprietates magneticas uniformes in tota structura componentis servant. Technologia munitii etiam valde ad gestionem thermicam confert, praebens certa schemata dispersionis caloris quae fiduciam systematis auxiliant. Ingeniarii valent praecipue facultatem circulos compactos, alti perficientiae designandi absque amplis experimentis de compatibilitate electromagnetica et cyclis redesignandi quae plerumque proiecta cum inductoribus conventionalibus vexant. Experimenta quaesturae qualitatis effectum munitii per omnes massas productionis verificant, fidam fiduciam in proprietatibus quae strictas normas automobilis, medicinae et industriae telecommunicationum satisfaciunt. Proprietates continendi magneticae stabiles manent per variationes temperaturae et conditiones stressis mechanicis, protectionem constantem per totam vitae operationalem producti praebentes. Praeterea, technologia munitii egetentiam minuit ad componentes additos compatibilitatis electromagneticae, velut granula ferrita, scuta cuprea, vel schemata speciales PCB, totam architecturam systematis simplicificans dum etiam impensas materialium et complexitatem coniunctionis in manufacturandis ambientibus minuit.