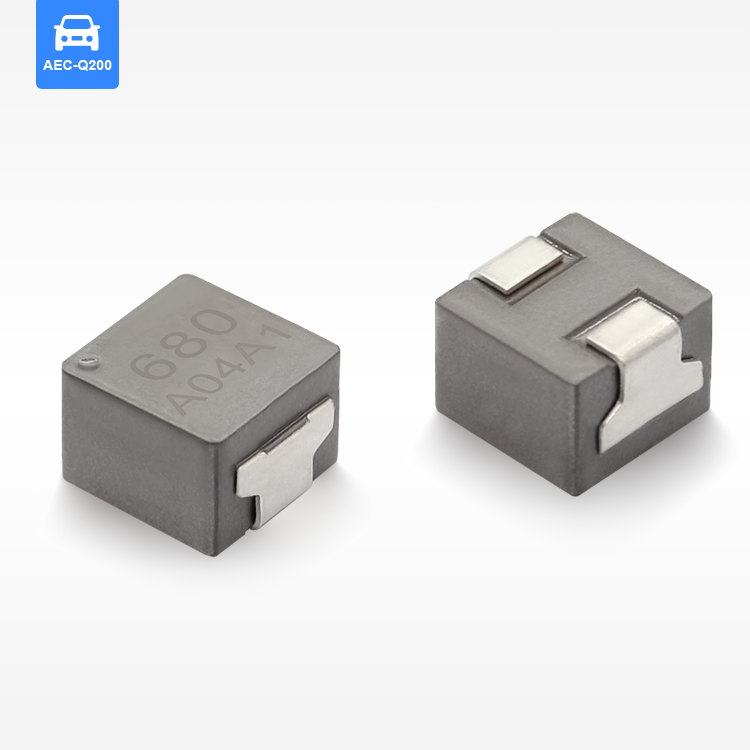

бага эсэргүүцэлтэй зурвасан цахилгааны шүргээ

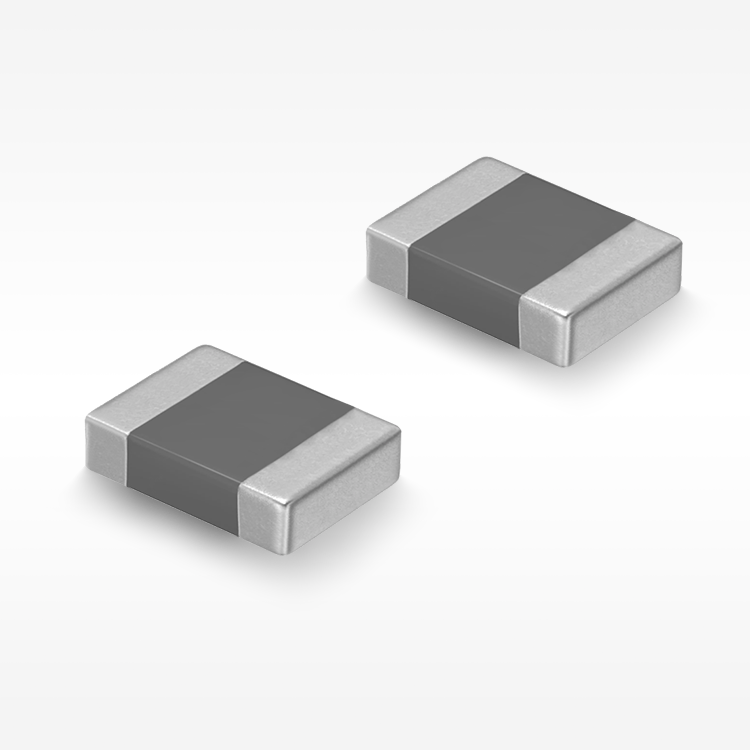

Бага эсэргүүцэлтэй хэвэнд оруулах цахилгаан соронзон ороомог нь цахилгаан хувиргалт болон шүүлтүүрийн хэрэглээнд агуу үйлчилгээтэй байх зориулалттай шинэлэг цахилгаан соронзон бүрэлдэхүүн хэсэг юм. Энэхүү дэвшилтэт ороомог нь шинэлэг хэвтэх технологийг цахилгаан шинж чанарыг сайжруулсантай хослуулан маш өндөр үр дүнтэй, найдвартай ажиллагааг хангана. Бага эсэргүүцэлтэй хэвэнд оруулах цахилгаан соронзон ороомог нь цахилгаан алдагдлыг хамгийн бага байлгах, мөн сайн соронзон шинж чанарыг хадгалахын тулд тусгайлан зохион бүтээсэн зүрхэвчийн материал болон нарийвчлалын ороомгийн аргачлалыг ашигладаг. Хэвэнд оруулах бүтэц нь тэсвэрт чанарыг сайжруулж, дулааныг зохицуулах чадавхийг нэмэгдүүлдэг тул хүнд нөхцөл байдалтай үйлдвэрлэл, худалдааны орчинд ашиглахад тохиромжтой. Энэхүү бүрэлдэхүүн хэсгийн үндсэн үүрэг бол цахилгаан хэлхээнд энерги хадгалах, гүйдлийг жигдруулах, цахилгаан соронзон саатлыг бууруулах явдал юм. Энэхүү бүрэлдэхүүн хэсэг нь ороомгийнхаа доторх гүйдэл урсах үед соронзон энерги хадгалж, түүнийгээ таслалт хийх үедээ тасралтгүй гүйдлийг хангах зорилгоор ялгаруулдаг. Энэ шинж чанар нь таслалттай цахилгаан хангамж, Тогтмол гүйдлийн хувирга, хүчдэлийн зохицуулагч зэрэг системд тогтвортой цахилгаан хангамжийг хангахад маш чухал үүрэг гүйцэтгэдэг. Технологийн онцлогт өндөр чанарын феррит эсвэл порошоктой төмөр зүрхэвчийг ашигласан бөгөөд эдгээр нь маш сайн нэвтрүүлэлт, бага зүрхэвчийн алдагдлыг хангана. Хэвэнд оруулах процесс нь бүх бүрэлдэхүүн хэсгийг хамарсан хамгаалалтай хайрцагт баглах замаар чийг, тоос, механик ачаалал зэрэг орчны хүчин зүйлсээс хамгаална. Дэвшилтэт ороомгийн байрлал нь гүйдлийн тархалтыг сайжруулж, эсэргүүцэлийг нэмэгдүүлж болох ойролцоох нөлөөллийг багасгадаг. Бага эсэргүүцэлтэй хэвэнд оруулах цахилгаан соронзон ороомог нь холбооны тоног төхөөрөмж, автомашин цахилгаан, сэргээгдэх эрчим хүчний систем, хэрэглээний электроник гэх мэт олон салбарт өргөнөөр ашиглагддаг. Цахилгааны менежментийн хэлхээнд эдгээр бүрэлдэхүүн хэсгүүд нь үр ашигтай цахилгаан хувиргалтыг хангаж, дулаан үүсгэлтийг бууруулж, нийт системийн найдвартай байдлыг сайжруулдаг. Бага эзлэхүүнтэй загвар, стандарт хэлбэр нь бага зайтай хэрэглээнд хялбархан суурилуулах боломжийг олгож, цахилгааны өндөр үйлчилгээг хадгалж чаддаг.