gemideki şarj cihazı için kalıplama gücü boğazı

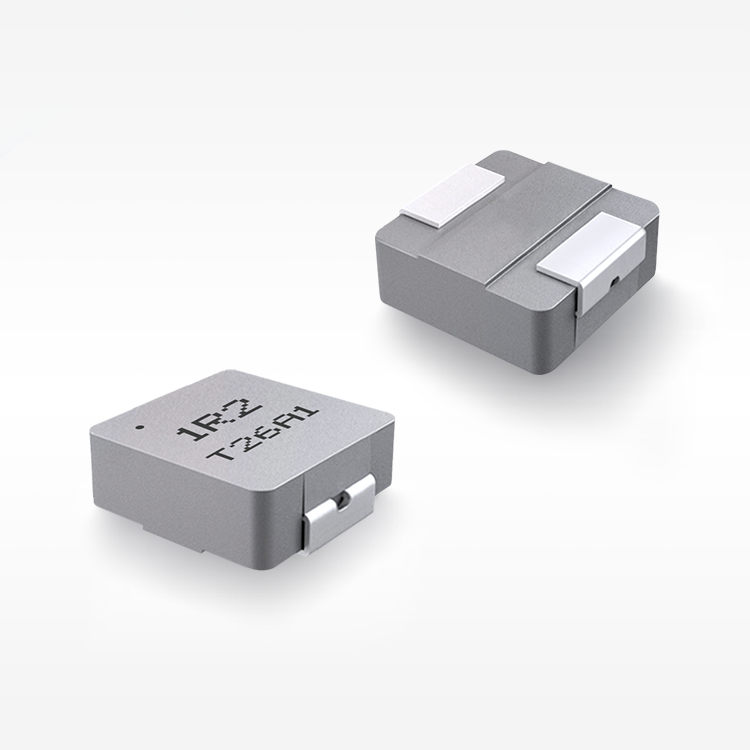

Şarj cihazı için kalıplanmış güç şok bobini, modern elektrikli araç şarj sistemlerinde kritik bir bileşen olup, şarj işlemi sırasında akım akışını düzenlemek ve kararlı güç sağını korumak üzere tasarlanmıştır. Bu özel indüktör, şarj esnasında şebeke akımından araç bataryasına kadar olan enerji transferini sabit tutmak için dalgalı akımları ve gerilim dalgalanmalarını düzeltici bir elektromanyetik filtre görevi görür. Şarj cihazı için kalıplanmış güç şok bobini, gelişmiş manyetik çekirdek malzemeleri ve dayanıklı bir kalıplama muhafazasına yerleştirilmiş hassas sarımlı bakır iletkenleri içerir; bu muhafaza, mükemmel termal yönetim ve çevre koruması sağlar. Bu bileşenin temel işlevi, manyetik enerjiyi geçici olarak depolayıp kontrollü bir şekilde serbest bırakarak elektromanyetik gürültüyü azaltmak ve aynı zamanda optimal şarj verimliliğini korumaktır. Teknolojik özellikleri yüksek frekanslı çalışma kabiliyeti, düşük çekirdek kayıpları ve değişen sıcaklık koşullarında güvenilir performansı sağlayan üstün termal iletkenliği içerir. Şarj cihazı için kalıplanmış güç şok bobini, olağanüstü manyetik geçirgenliğe ve en düşük histerezis kayıplarına sahip ferrit veya demir tozu çekirdekler kullanır ve bu da sistemin genel verimliliğine katkı sağlar. İleri üretim süreçleri, üretim partileri boyunca sıkı tolerans kontrolü ve tutarlı elektriksel karakteristiklerin sağlanmasını garanti eder. Kalıplanmış yapı, nem, toz ve titreşime karşı mekanik stabilite ve koruma sağlar ve bu nedenle güvenilirliğin ön planda olduğu otomotiv uygulamaları için uygundur. Uygulama alanları, tam elektrikli araçlar (BEV), takılabilir hibrit elektrikli araçlar (PHEV) ve ticari elektrikli taşıma sistemleri dahil olmak üzere çeşitli elektrikli araç platformlarını kapsar. Şarj cihazı için kalıplanmış güç şok bobini, şarj performansını en iyi hale getirmek amacıyla güç faktörü düzeltme devreleri, DC-DC dönüştürücüler ve batarya yönetim sistemleriyle sorunsuz entegre edilir. Yüzeye montaj ve delikli montaj (through-hole) konfigürasyonları için esnek kurulum imkânı sunarak çeşitli PCB yerleşimlerine ve alan kısıtlamalarına uyum sağlar. Kalite güvence protokolleri, elektriksel performans, termal çevrim testleri ve çevresel dayanıklılık için otomotiv endüstrisi standartlarına ve yönetmeliklere uygunluk açısından kapsamlı testleri içerir.