korumalı güç endüktörü fabrikası

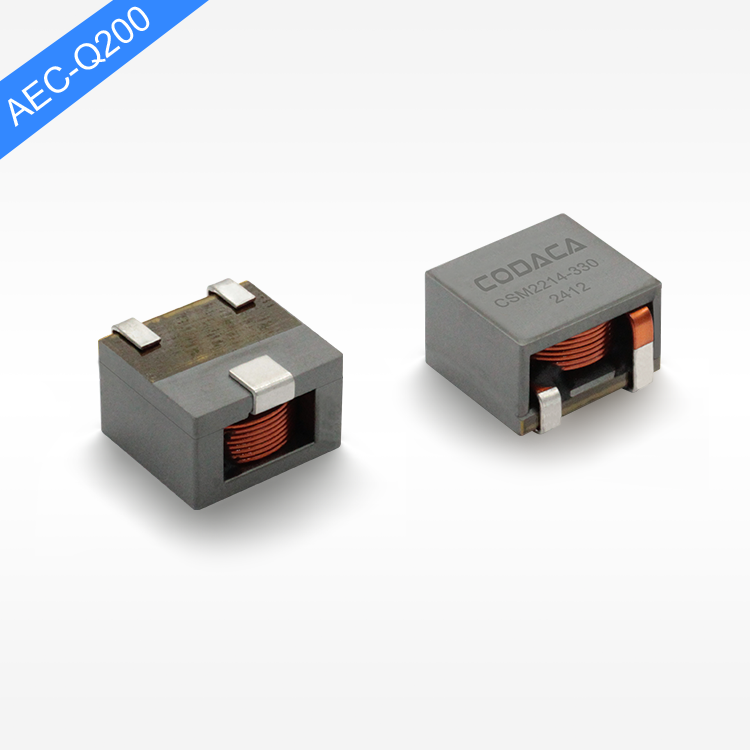

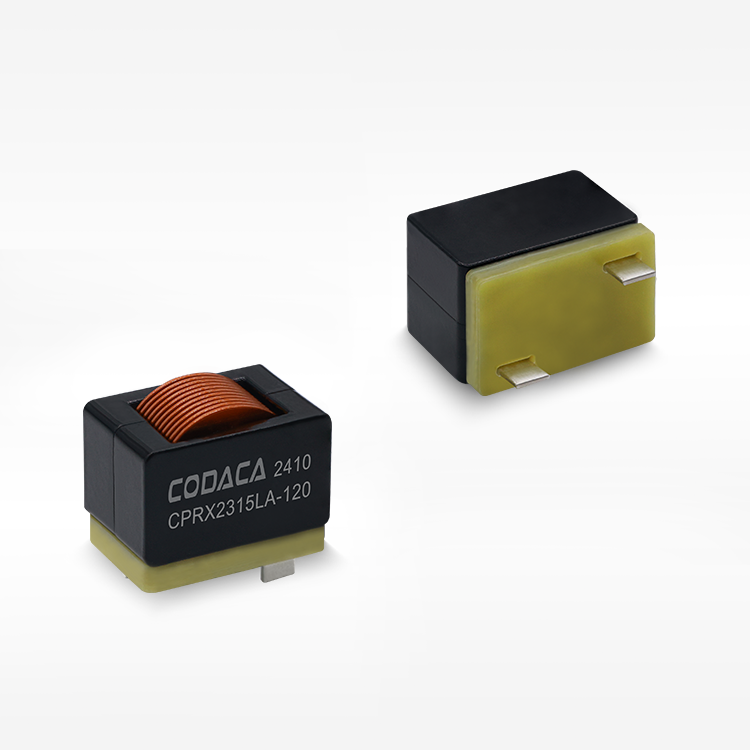

Koruyuculu güç indüktörü fabrikası, modern elektronik sistemler için gerekli olan yüksek performanslı elektromanyetik bileşenleri üretmeye adanmış özel bir üretim tesisini temsil eder. Bu gelişmiş üretim tesisleri, elektromanyetik paraziti önlerken aynı zamanda optimal güç verimliliğini koruyan manyetik kalkanlı indüktörlerin üretimine odaklanır. Koruyuculu güç indüktörü fabrikasının temel işlevi, genellikle ferrit malzemelerden veya toz haline getirilmiş demir bileşiklerinden yapılan kapalı manyetik çekirdekli indüktörleri tasarlamak, mühendislikle geliştirmek ve seri olarak üretmektir. Koruyuculu güç indüktörü fabrikası, tüm üretilen birimlerde tutarlı elektriksel karakteristikler sağlamak için gelişmiş sarma tekniklerini ve hassas montaj süreçlerini kullanır. Bu tesisler, ürün kalite standartlarını korumak amacıyla otomatik bobin sarma makineleri, bilgisayar destekli test ekipmanları ve temiz oda ortamlarını içeren son teknolojiyi entegre eder. Modern bir koruyuculu güç indüktörü fabrikasının teknolojik özellikleri arasında gelişmiş manyetik alan simülasyon yazılımları, endüktans değerleri için hassas ölçüm cihazları ve çevresel koruma amaçlı özel kaplama uygulamaları yer alır. Koruyuculu güç indüktörü fabrikasındaki kalite kontrol sistemleri, elektriksel özelliklerin, termal performansın ve mekanik dayanıklılığın doğrulanmasını sağlamak amacıyla katı test protokollerini uygular. Bir koruyuculu güç indüktörü fabrikasında üretilen ürünlerin uygulama alanları otomotiv elektroniği, telekomünikasyon altyapısı, bilgisayar güç kaynakları, LED aydınlatma sistemleri ve yenilenebilir enerji dönüştürücülerini içeren birçok sektörü kapsar. Koruyuculu güç indüktörü fabrikası, DC-DC dönüştürücüler, anahtarlamalı güç kaynakları ve enerji depolama sistemleri için bileşen üretimi gibi kritik görevler üstlenir. Modern üretim süreçleri, koruyuculu güç indüktörü fabrikasında verimli malzeme kullanımı, atık azaltma programları ve enerji verimli üretim yöntemleri aracılığıyla çevresel sürdürülebilirliğe önem verir. Tesis genellikle üretilen ürünlerin küresel pazarda kabul görmesini sağlamak adına ISO kalite standartları, otomotiv endüstrisi spesifikasyonları ve çevre uyumluluk gereklilikleri gibi sertifikalara sahip olur.