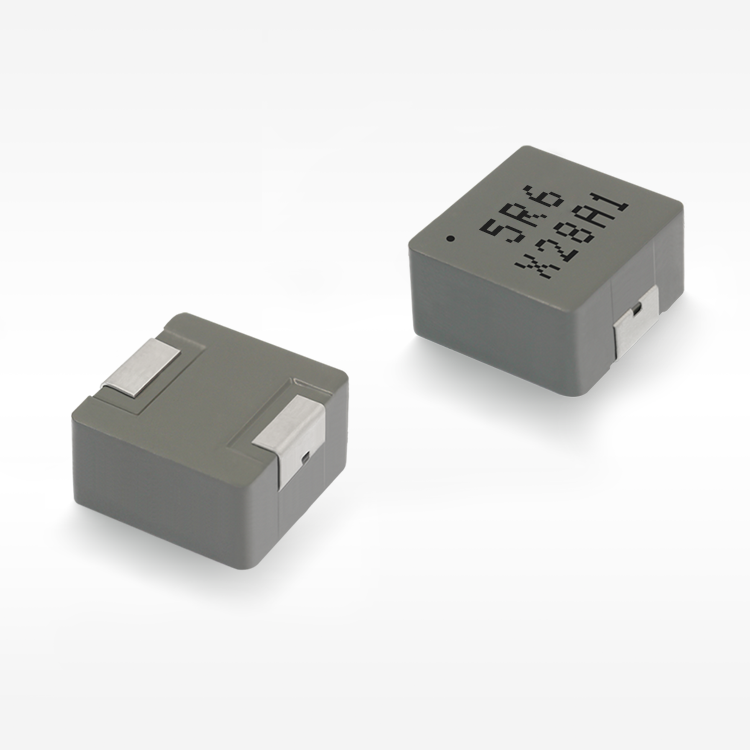

shakllantirilgan kuch induktori

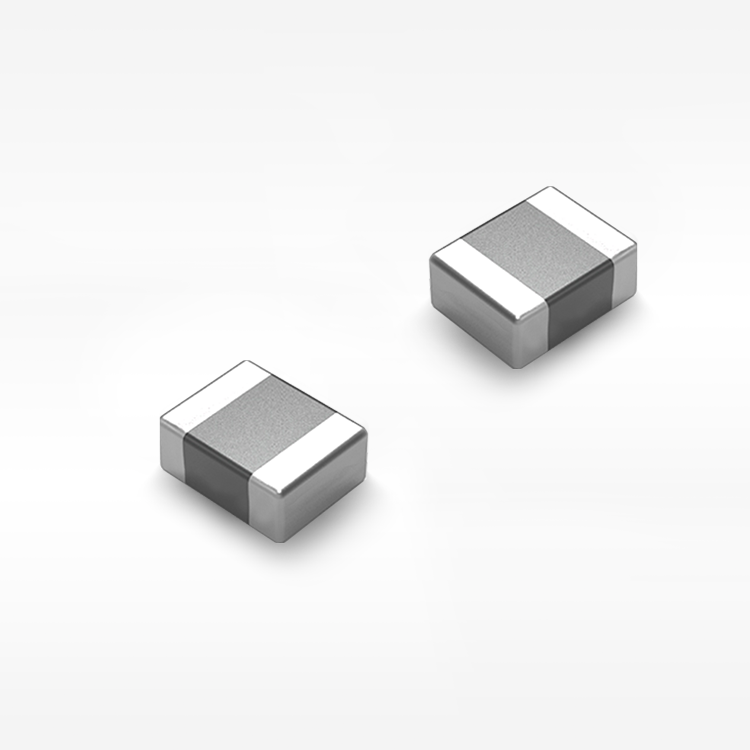

Formalangan quvvat induktori magnit maydonlarda energiyani saqlash va quvvat manbai elektr zanjirlaridagi tok oqimini boshqarish uchun mo'ljallangan muhim elektron komponentdir. Ushbu murakkab qurilma bakal, shaffof yoki boshqa maxsus materiallar ichiga o'ralgan mis simdan iborat bo'lib, zamonaviy elektronikaga qulay hamda samarali yechim taklif etadi. Formalangan kuch induktorining asosiy vazifalari orasida energiya saqlash, tokni filtrlash, kuchlanishni tartibga solish hamda elektromagnit to'sqinliklarni pasaytirish bor. Bu texnologiya elektromagnit induksiya tamoyiliga asoslanadi: simdan tashkil topgan spiral tok oqimidagi o'zgarishlarga qarshilik ko'rsatuvchi magnit maydon hosil qiladi. Ishlab chiqarish jarayonida aylanma simni aniq o'ram usullari bilan birgalikda maxsus formaga ega korpusga joylashtirish amalga oshiriladi, bu esa qurilmaning ishlash samaradorligi hamda chidamliligini ta'minlaydi. Bu komponentlar past doimiy tok qarshiligi, yuqori to'yinish tok qiymatlari hamda ajoyib issiqlik barqarorligi jihatidan ajralib turadi va shu sababli qattiq talablarni qo'yadigan sohalarda foydalanish uchun ideal hisoblanadi. Formalangan konstruksiya an'anaviy simli analoglardan yaxshiroq mexanik mustahkamlikka ega bo'lib, turli atrof-muhit sharoitlarida barqaror elektr xususiyatlarini saqlaydi. Asosiy texnik xususiyatlarga moslashtiriladigan induktivlik qiymatlari, ixcham o'lchamlar hamda sanoat talablariga javob beradigan yaxshilangan quvvat boshqarish imkoniyati kiradi. Qo'llanilishi o'zgartiruvchi quvvat manbalari, DC-DC konvertorlar, avtomobil elektronikasi, aloqa uskunalari hamda qayta tiklanadigan energiya tizimlari kabi sohalarni qamrab oladi. Formalangan kuch induktor dizayni portativ qurilmalar, sanoat avtomatlashtirish tizimlari hamda yuqori chastotali kalitlash zanjirlarida samarali quvvat boshqarish imkonini beradi. Yaxshilangan materialshunoslik magnit o'tkazuvchanlikni oshirish va yadro yo'qotishlarini kamaytirish orqali umumiy tizim samaradorligini oshirishga hissa qo'shadi. Harorat barqarorligi keng ishlatish diapazonida ishonchli ishlashni ta'minlaydi, formalangan korpus esa namlik, chang hamda mexanik kuchlanish kabi atrof-muhit omillaridan himoya qiladi.