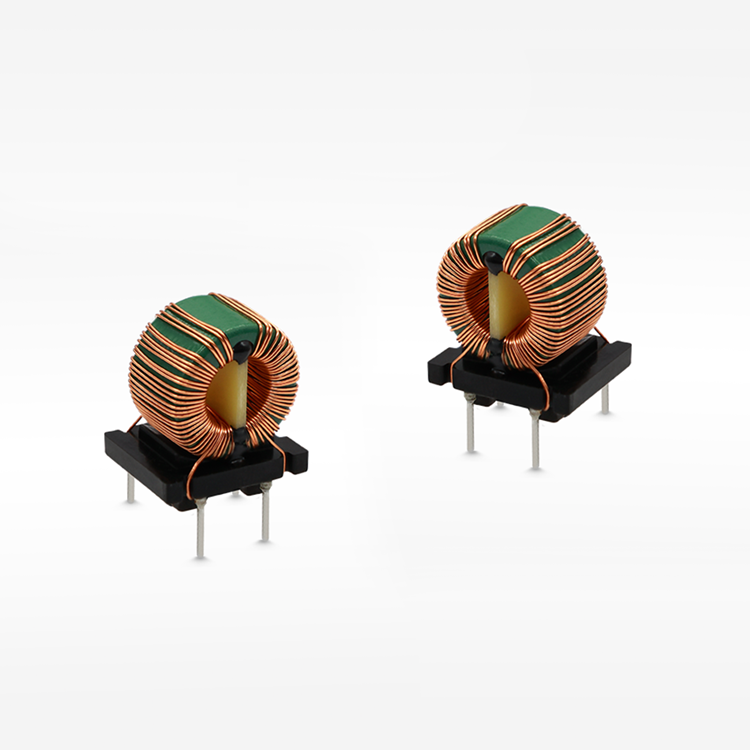

power line common mode choke factory

Servicing a factory line which manufactures common mode chokes (CMC) for power lines is the Power Line Common Mode Choke Factory. These elements perform a vital function by checking out electromagnetic interference(EMI) in power systems. That makes the stable and reliable operation of electric equipment possible. One feature of the factory's advanced technology is its advanced equipment, which includes several automatic production lines and strict control systems designed to ensure quality assurance. Designed to have high saturation current, low insertion loss, and excellent temperature stability, what Radiohm makes here are the common mode chokes. It is applied in fields ranging from telecommunication to consumer electronics;string information products all over offices;automotive and industrial automation.