Application Note

-

Humanoid robot inductor product requirements and application selection

The growing demand for automation in manufacturing and service industries is driving the rapid development of humanoid robots. With the increase in degrees of freedom (DOF) and the improvement of response speed to the environment, humanoid robots have become more sophisticated, allowing them to simulate human movements more realistically.

Dec. 31. 2025 -

Challenges in Medical Electronic Power Design and Inductor Product Requirements

Inductors play a crucial role in medical power supply systems and must meet the high requirements of medical power supply equipment. Therefore, when selecting products, factors such as high reliability, low noise, high efficiency, and EMI resistance need to be considered. Codaca independently develops and manufactures multiple series of inductors, including high current power inductors, molded inductors, and common mode chokes, which have been widely applied in medical devices and components such as ultrasound detectors, blood analyzers, ventilators, blood pressure monitors, and rehabilitation robots.

Dec. 02. 2025 -

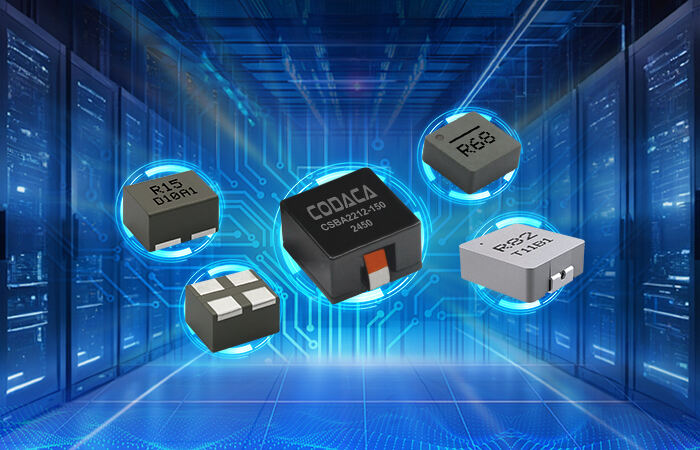

The power technology of AI servers continues to evolve, driving the demand for high-performance inductors

Inductors face multiple challenges in AI server power systems, including high current, small size, high frequency, strong anti-interference, wide temperature adaptation, and low noise. To meet the stringent application requirements under new trends, continuous progress through material innovation, structural optimization, and process upgrades is necessary.Codaca has focused on high-reliability inductor solutions and has launched multiple high-performance inductor products for AI servers and related intelligent devices, covering various categories such as super high current power inductors, compact high current power inductors, and molded low-inductance high-current inductors.

Dec. 01. 2025 -

Selection of power inductor for bidirectional DC-DC converter in household storage

Codaca has provided multiple adapted inductor solutions for residential bidirectional DC-DC converters through independent R&D and technological innovation, contributing to green and low-carbon development. CODACA has launched multiple models of high current power inductors, offering various electrical characteristics and package designs to meet the high-performance requirements of the inductors for this application.

Nov. 28. 2025 -

Decoding Qualcomm Automotive Domain Controller first-stage Power Supply Design: Performance Test Measurement Analysis

As an important component of the first-stage power supply in automotive domain controllers, the performance of inductors is crucial to the reliability and conversion efficiency of DC-DC switching power supplies. In this design solution, the CODACA automotive-grade Molded Power Inductor VSEB0660-1R0M is adopted.

Nov. 27. 2025 -

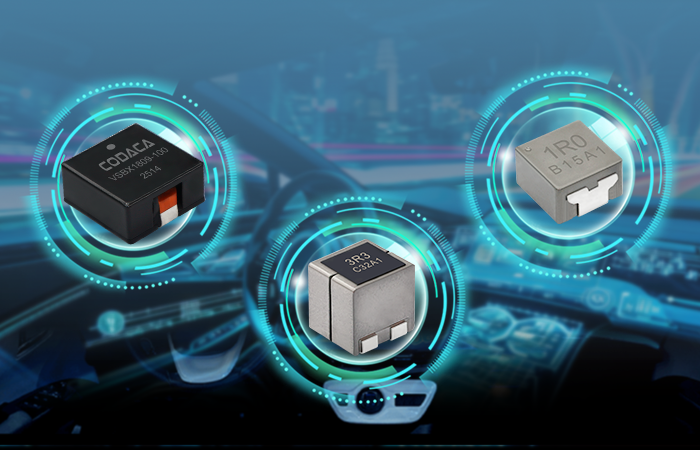

High-reliability automotive-grade inductors help make automotive cockpits more efficient and smarter

Cabin design is related to the driving and riding comfort and safety of a vehicle. Smart cabins integrate various IT and artificial intelligence technologies to create an integrated digital platform inside the car, providing drivers with a smart experience and promoting driving safety.

Nov. 26. 2025 -

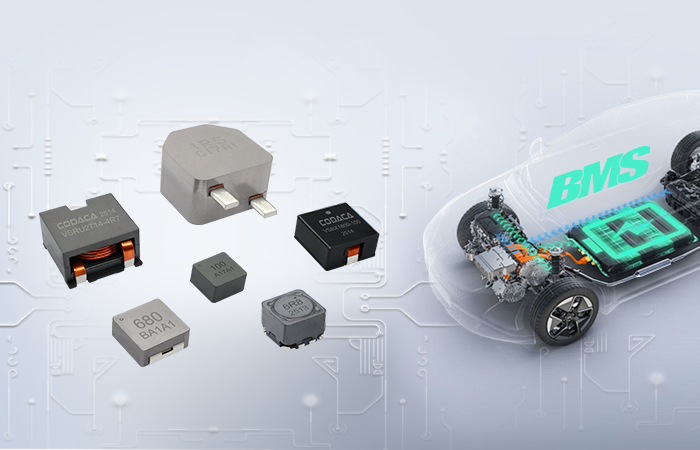

To improve the safety and efficiency of new energy vehicles, Codaca provides high-performance automotive-grade inductors for automotive BMS

In the automotive BMS system, inductors are primarily used in power conversion, balancing circuits, and filtering circuits, with specific applications and requirements as follows.Codaca has independently developed several series, including automotive-grade molded power inductors, automotive-grade high current power inductors, and automotive-grade common mode chokes, to meet the design requirements of automotive electronics miniaturization, integration, low loss, and high efficiency.

Oct. 24. 2025 -

Codaca: Crafting high-quality automotive-grade inductors with ingenuity to drive innovation and upgrades in automotive electronics products

All along, Codaca has been committed to providing low-loss, high-reliability automotive-grade inductor solutions for automotive electronics, strictly adhering to the IATF16949 automotive quality management system requirements for automotive product quality control. German customers adopt the VDA6.3 standard. At the same time, Codaca strictly selects raw material suppliers and conducts comprehensive incoming material testing. The product development process strictly follows APQP, emphasizing early quality planning, manufacturing process control, process management, quality traceability management, and more. Digital management methods are used to improve production efficiency and achieve full-process traceability of product quality.

Oct. 23. 2025 -

Exploding computing power! Codaca 's high-performance inductors help improve the energy efficiency of data center power systems

Codaca inductors are widely used in data center switches, routers, storage systems, and monitoring systems, including high-current inductors, integral inductors, common-mode/surface mount inductors, and more, all of which can be flexibly customized according to customer needs.

Oct. 22. 2025 -

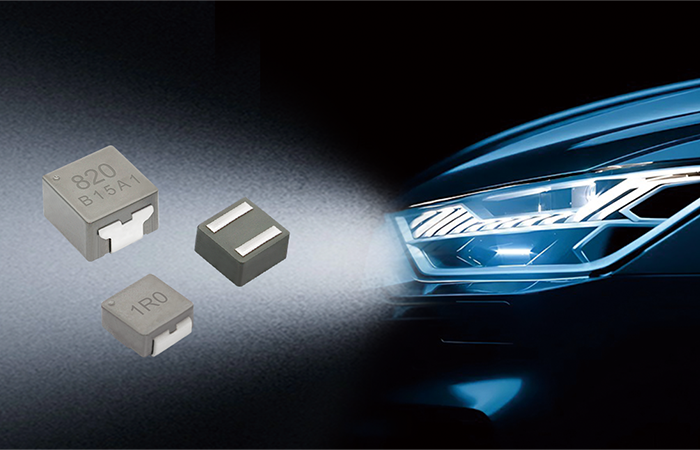

Low-loss, high-reliability automotive-grade inductors help improve the energy efficiency and reliability of automotive lighting systems

Automotive lighting LED driver power supply circuits utilize numerous power inductors. Due to the complex operating environment of automotive lighting circuits, inductors must withstand multiple challenges, including high temperature, high frequency, high current, mechanical vibration, and shock. Furthermore, they must meet the requirements of small size, electromagnetic interference resistance, and high-density mounting brought about by the miniaturization of automotive electronics.

Oct. 21. 2025 -

Bottom-Electrode Molded Power Inductor Selection Guide

the bottom-electrode molded power inductor, with its compact structure, high reliability, and excellent performance, has become a preferred component for high-density, high-frequency electronic systems. Its comprehensive performance is superior to that of traditional wire-wound inductors, especially in applications pursuing miniaturization, high reliability, and low EMI.

Sep. 25. 2025 -

Generation and Countermeasures of Electromagnetic Interference (EMI) in Electronic Equipment

To help electronic devices solve EMI/EMC issues, Codaca has developed various series of standardized signal line common mode chokes, power line common mode chokes, differential mode chokes, ferrite beads, and various magnetically shielded power inductors.

Sep. 24. 2025