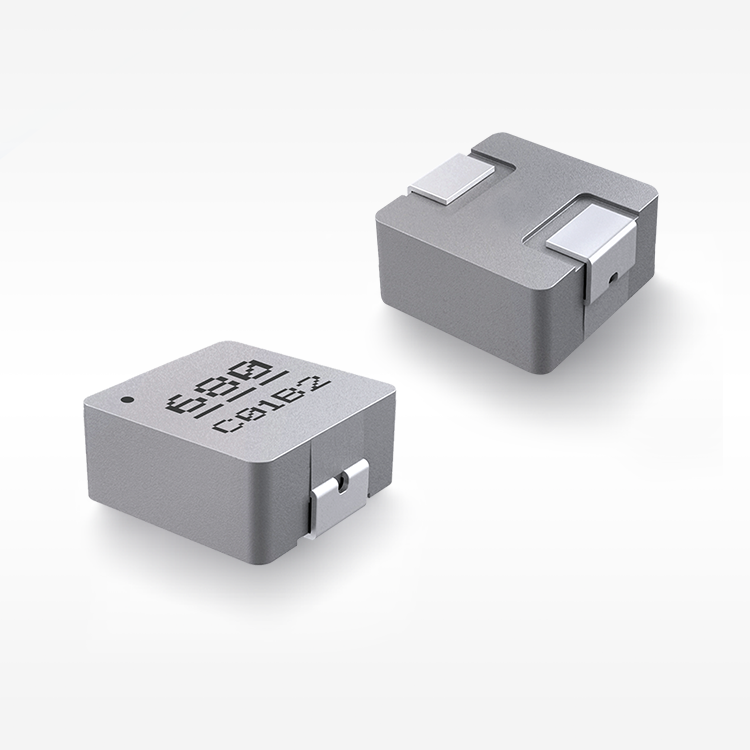

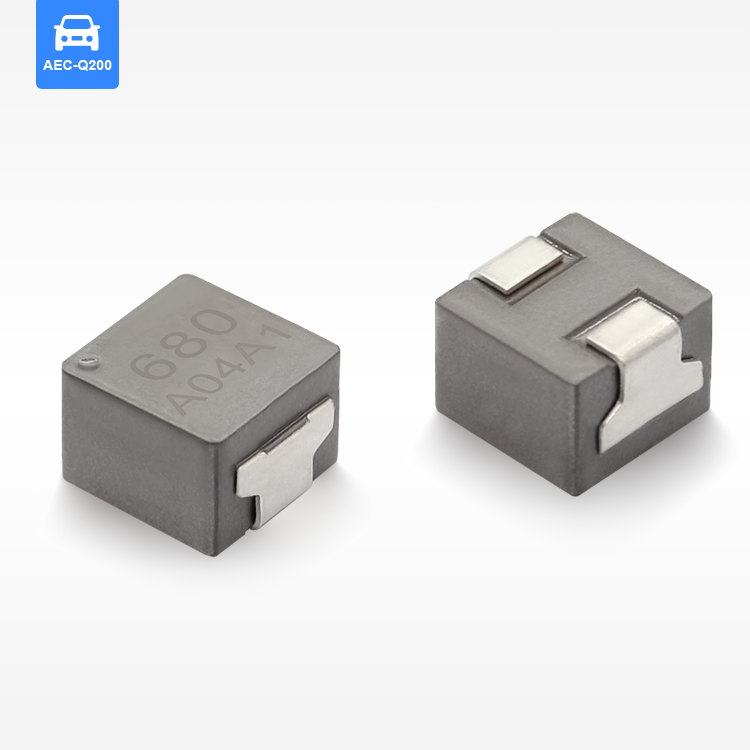

shielded molding power choke

The shielded molding power choke represents a critical component in modern electronic systems, designed to provide superior electromagnetic interference suppression and power filtering capabilities. This sophisticated inductor utilizes advanced magnetic shielding technology combined with precision molding techniques to deliver exceptional performance in demanding applications. The primary function of a shielded molding power choke involves filtering unwanted noise and harmonics from power supply circuits while maintaining stable current flow. The magnetic core construction enables efficient energy storage and release, making it essential for power conversion systems. The shielding mechanism prevents electromagnetic radiation from escaping the component while simultaneously protecting internal circuitry from external interference. Technological features include high-permeability ferrite cores that maximize inductance values within compact form factors. The molding process ensures consistent manufacturing tolerances and enhanced mechanical durability. Advanced winding techniques optimize current handling capacity while minimizing resistance losses. Temperature stability characteristics allow operation across wide environmental ranges without performance degradation. The shielded molding power choke finds extensive applications in switch-mode power supplies, DC-DC converters, automotive electronics, and industrial control systems. Telecommunications equipment relies on these components for signal integrity preservation. Consumer electronics benefit from reduced electromagnetic emissions and improved power efficiency. Medical devices utilize shielded molding power chokes for critical safety compliance requirements. The component's versatility extends to renewable energy systems, where power conditioning demands precise current regulation. Manufacturing processes incorporate automated production lines ensuring consistent quality standards. Quality control procedures verify electrical parameters, mechanical specifications, and environmental compliance. The shielded molding power choke continues evolving with emerging technologies, incorporating new materials and design methodologies to meet increasingly stringent performance requirements in next-generation electronic systems.