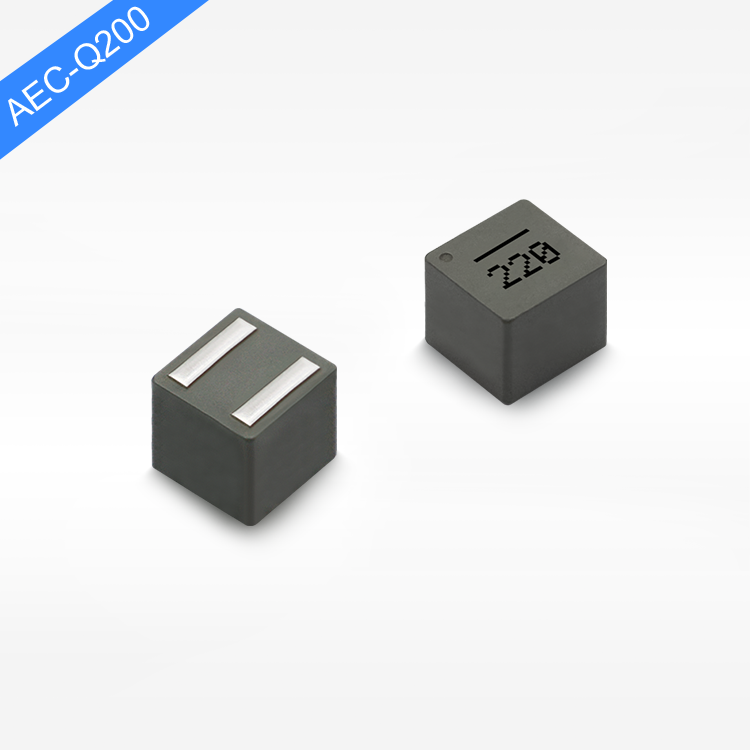

L'inductance blindée haute intensité offre plusieurs avantages très bénéfiques pour les clients. Tout d'abord, sa capacité à supporter des courants élevés sans saturation assure une performance stable dans des applications exigeantes. Ensuite, le blindage réduit efficacement les EMI, ce qui se traduit par des signaux plus propres et une meilleure fonctionnalité globale du système. Troisièmement, ses dimensions compactes et sa conception robuste facilitent son intégration dans divers appareils électroniques, permettant ainsi de gagner de la place et de réduire les coûts de fabrication. Enfin, la fiabilité de l'inductance garantit une durée de vie plus longue pour les équipements électroniques, réduisant ainsi les coûts de maintenance et de remplacement à long terme.