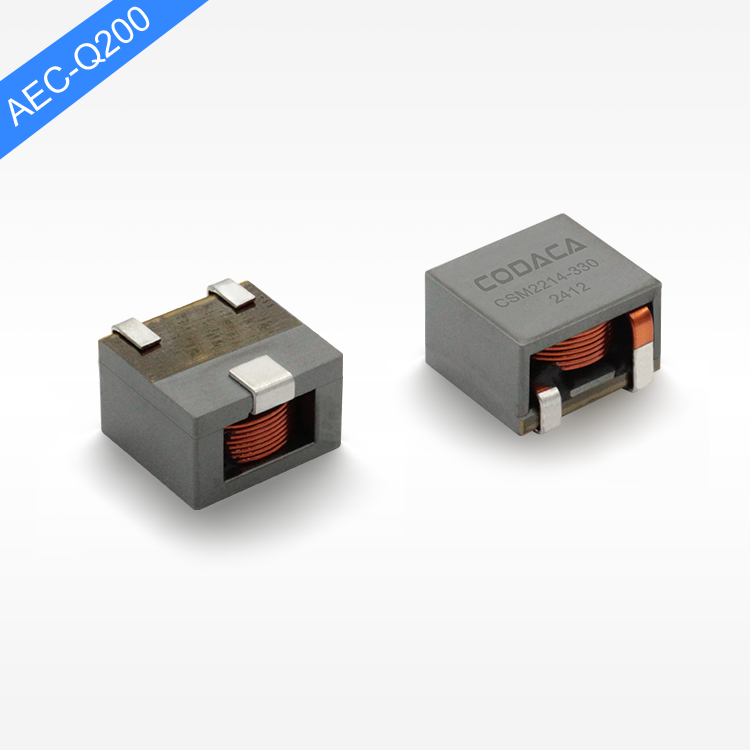

שונאי מגנטי מוכסה לפי הזמנה

סליל מותאם עם שיקוף מגנטי מייצג רכיב אלקטרומגנטי מתקדם שתוכנן במיוחד כדי לעמוד בדרישות יישום ספציפיות תוך מינימום של הפרעות אלקטרומגנטיות. סלילים מיוחדים אלו כוללים טכנולוגיית שיקוף מגנטית מתקדמת אשר אוסרת את השדה המגנטי בתוך הרכיב, וכך מונעתปฏולות לא רצויות עם מעגלים סמוכים וציוד אלקטרוני רגיש. הפונקציה העיקרית של סליל מותאם עם שיקוף מגנטי היא אגירת אנרגיה בשדה המגנטי שלו, תוך סינון, חלקה או חסימה של תדירויות מסוימות במעגלי חשמל. בניגוד לסלילים סטנדרטיים, רכיבים אלו כוללים שיקופים מגנטיים שתוכננו בקפידה שמפחיתים בצורה דרמטית שידור שדות מגנטיים חיצוניים ומحمים מפני הפרעות אלקטרומגנטיות פנימיות. היסודות הטכנולוגיים של סלילי שיקוף מגנטי מותאמים מבוססים על סלילים עטופים בדיוק בשילוב עם חומרים מגנטיים בעלי חדירות גבוהה היוצרים מחסומים מגינים סביב ליבת הסליל. מנגנון השיקוף עושה שימוש בחומרי פריט, מתכת מ'יו' (mu-metal) או סגסוגות מגנטיות מיוחדות אחרות שמפנות קווי שטף מגנטי מרחפים רגישים. תהליכי הייצור כוללים טכניקות עטיפה מדויקות, גאומטריות ליבה מבוקרות ועיצובי מסלול מגנטי מואפלים שמקסמים את ההשראות תוך מינימום של איבודים. סלילי שיקוף מגנטי מותאמים משמשים בצורה נרחבת במגוון תעשיות, כולל אלקטרוניקה אוטומotive, ציוד רפואי, ציוד תקשורת, מקורות כוח ומערכות תעופה. ביישומים אוטומotive, סלילים אלו מנהלים את המרת האנרגיה ברכבים חשמליים, מערכות היברידיות ומערכות עזר לנהיגה מתקדמות, בהם התאמה אלקטרומגנטית היא קריטית. יצרני ציוד רפואי סומכים על סלילי שיקוף מגנטי מותאמים לצורכי MRI, מערכות ניטור חולים ומכשירים ניתנים שתילה, בהם הפרעות אלקטרומגנטיות עלולות לסכן את בטיחות החולים. תשתיות תקשורת עושים שימוש ברכיבים אלו בתחנות בסיס, ציוד עיבוד אותות ומפסקים רשת, בהם שלמות האות דורשת בידוד אלקטרומגנטי מתקדם. היכולת להתאים אישית מאפשרת להנדסאים לציין ערכים מדויקים של השראות, דירוגי זרם, תדירויות פעילות ומימדים פיזיים המתאימים בדיוק לדרישות היישום, ומבטיחה ביצועים אופטימליים בסביבות קשות.