אמינות ועמידות יוצאות דופן מבטיחות ביצועים לאורך זמן

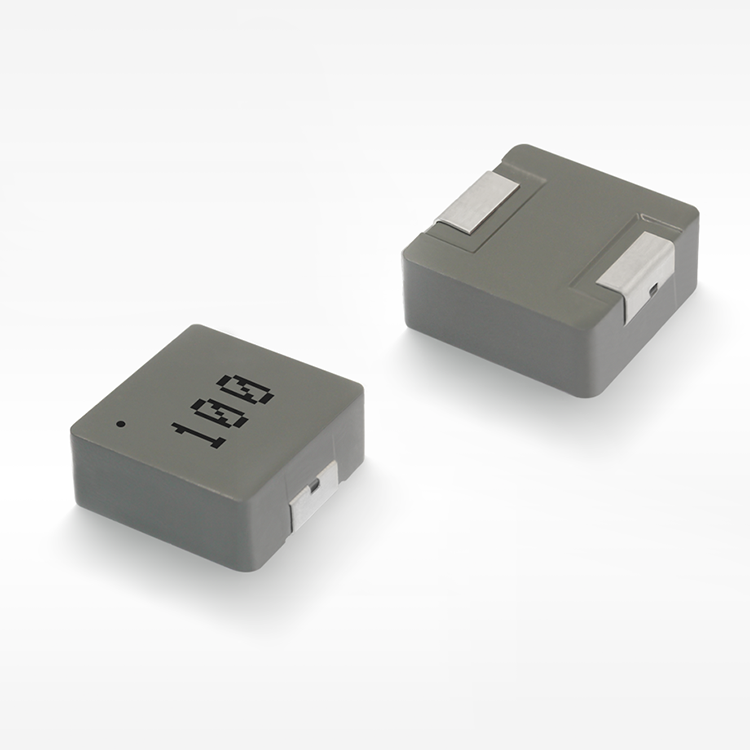

סלילים בעלי יעילות גבוהה ומבוזלים מגנטית מספקים אמינות ועמידות חסרות תחרות, מה שהופך אותם לבחירה המועדפת ביישומים קריטיים למשימה שבה כשל אינו אפשרות. האמינות החריגה נובעת מעיצוב מגנטי סגור שמגן על רכיבי הפנימיים מפני סיכוני סביבה כגון לחות, אבק, זיהום כימי ורטט מכני. הגנה זו חשובה במיוחד בסביבות עבודה קשות כמו comparטמנטים של מנועים ברכב, מתקני ייצור תעשייתיים וציוד תקשורת חיצוני, שבהם החשיפה לתנאים קיצוניים היא בלתי נמנעת. מבנה הביזול המגנטי עצמו תורם ליציבות מכנית על ידי סיפוק תמיכה מבנית נוספת לסלילי הסליל ולצינור הליבה, ובכך מפחית את הסיכון לנזק כתוצאה מהדחק ורטט. היתרונות של עמידות של סלילים בעלי יעילות גבוהה ומבוזלים מגנטית מתרחבים גם לביצועים תרמיים, כאשר ייצור חום מופחת מאריך משמעותית את מחזור החיים של הרכיב. סלילים מסורתיים הפועלים ברמות הספק גבוהות סובלים לעיתים קרובות מגריעת חום של חומרי בידוד, חמצון של מוליכים ושינויים בחומר הליבה, מה שגורם להזזת ביצועים וכשל גורף. סלילים בעלי יעילות גבוהה ומבוזלים מגנטית שומרים על טמפרטורות פעילות יציבות גם בתנאים קשים, משמרים את תכונות החומר ודואגים לביצועים חשמליים עקביים לאורך פרקי זמן ארוכים. יצרנים רבים כפופים לרכיבים אלו לاجירת חיים מאיצה קפדנית שמדמה שנים של פעולה בתנאים קיצוניים, ומאמתת טענות אמינות לטווח ארוך. תהליכי בקרת איכות בהן נעשה שימוש בייצור סלילים בעלי יעילות גבוהה ומבוזלים מגנטית עולים בדרגתם על תקני התעשייה, וכוללים נקודות בדיקה מרובות, הליכי בדיקה אוטומטיים ושיטות שליטה בתהליך סטטיסטי כדי להבטיח איכות עקיבה. אמצעי איכות אלו מייצרים קצב כשלים נמוך ביותר, שנמדד לעתים קרובות בחלקים למיליון, ונותנים אמון למפתחים העוסקים ביישומים קריטיים כמו התקני רפואה, מערכות תעופה וציוד בטיחות, בהם כשל רכיב עלול להביא לעקיפות חמורות. התכונות החשמליות צפויות של סלילים בעלי יעילות גבוהה ומבוזלים מגנטית במהלך מחזור החיים שלהם מפשטות את עיצוב המעגל ומחסכות בצורך בחשבון שולי ביצועים שמגדילים את העלות והמורכבות של מערכות אלקטרוניות. יציבות זו גם מפחיתה את דרישות התפעול והתחזוקה ומאריכה את תקופות השירות, ונותנת חיסכון נוסף לאורך מחזור החיים של המוצר. ליישומים הדורשים זמינות גבוהה כמו מרכזי נתונים, תשתיות תקשורת ומערכות תגובה למקרים חירום, האמינות החריגה של סלילים בעלי יעילות גבוהה ומבוזלים מגנטית עוזרת להבטיח פעילות מתמשכת ומזערת אירועים יקרים של השבתה.