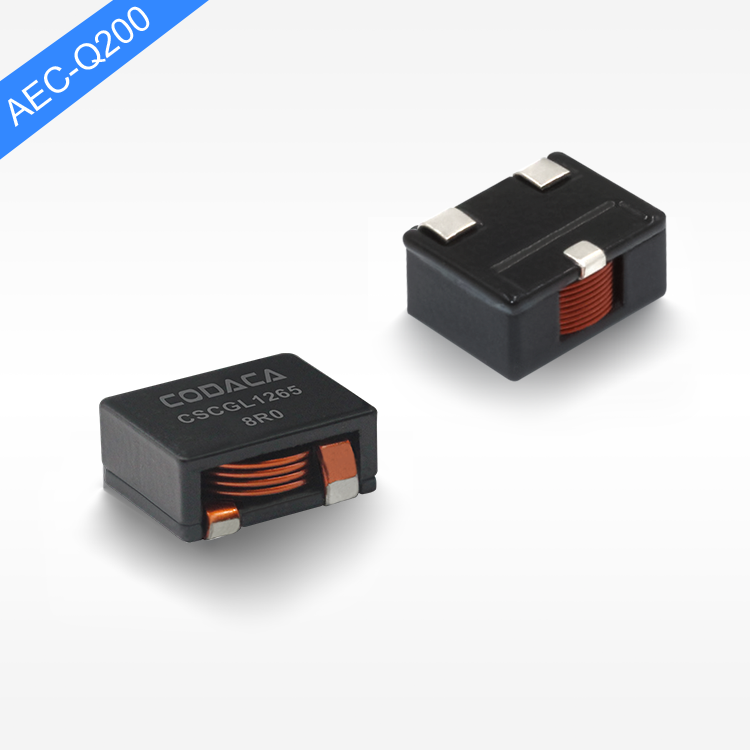

סליל תייל שטוח לזרם גבוה

הסליל בעל החוט השטוח והזרם הגבוה מייצג התקדמות מהפכנית בטכנולוגיית רכיבים אלקטרומגנטיים, שתוכננה במיוחד כדי להתמודד עם עומסי חשמל משמעותיים תוך שמירה על יעילות ואמינות יוצאות דופן. סליל זה חדשני משתמש בבנייה של חוט נחושת שטוח במקום חוט עגול מסורתי, ומייצר רכיב שמציע ביצועים מוכחים ביישומים של זרם גבוה. הסליל בעל החוט השטוח והזרם הגבוה ממלא מספר פונקציות חשובות במערכות אלקטרוניות, בעיקר כמכשיר לאחסון אנרגיה שמחליק את זרימת הזרם ומחזיר הפרעות אלקטרומגנטיות. התכונה הטכנולוגית המרכזית שלו נמצאת בריכוך הייחודי של החוט השטוח, שמגדיל למקסימום את שטח הפנים של המוליך, תוך מינימום של התנגדות וייצור חום. העיצוב הזה מאפשר לסליל בעל החוט השטוח והזרם הגבוה להתמודד עם רמות זרם גבוהות בהרבה בהשוואה לסלילים קונבנציונליים באותו גודל. הרכיב פועל על ידי איחסון אנרגיה בשדה המגנטי שלו כאשר זרם זורם דרך הליפופים, ואז משחרר אנרגיה זו חזרה למעגל לפי הצורך. פעילות בסיסית זו הופכת את הסליל בעל החוט השטוח והזרם הגבוה לחיוני ליישומי ניהול כוח, ממירי DC-DC, וספקי כוח מתחלפים. הרמה הטכנולוגית מתרחבת גם לחומרי הליבה, שכוללים לרוב ליבות פריט או ברזל אבקתי בעלי חדירות גבוהה, המשפרים את עוצמת השדה המגנטי ומשפרים את הביצועים הכוללים. יישומים של הסליל בעל החוט השטוח והזרם הגבוה משתרעים על פני תעשיות רבות, כולל אלקטרוניקה אוטומotive, מערכות אנרגיה מתחדשת, אוטומציה תעשייתית, תשתיות תקשורת ואלקטרוניקה לצרכן. ברכב חשמלי, סלילים אלו מנהלים את המרת הכוח בין סוללות למנועים, בעוד שבמיתגי סולאריים הם מבטיחים מסירת כוח חלקה מלוחות לרשת. העיצוב הדחוס של הסליל בעל החוט השטוח והזרם הגבוה הופך אותו לערכה במיוחד ביישומים שבהם יש מגבלות של שטח, ובהם סלילים מסורתיים יהיו לא מעשיים. תהליכי ייצור כוללים טכניקות ריכוך מדויקות שמונעות רווח אחיד וצימוד מגנטי אופטימלי, ונותנות מאפיינים חשמליים צפויים ואמינות משופרת בתנאי פעולה שונים.