강력한 구조와 장기적 신뢰성

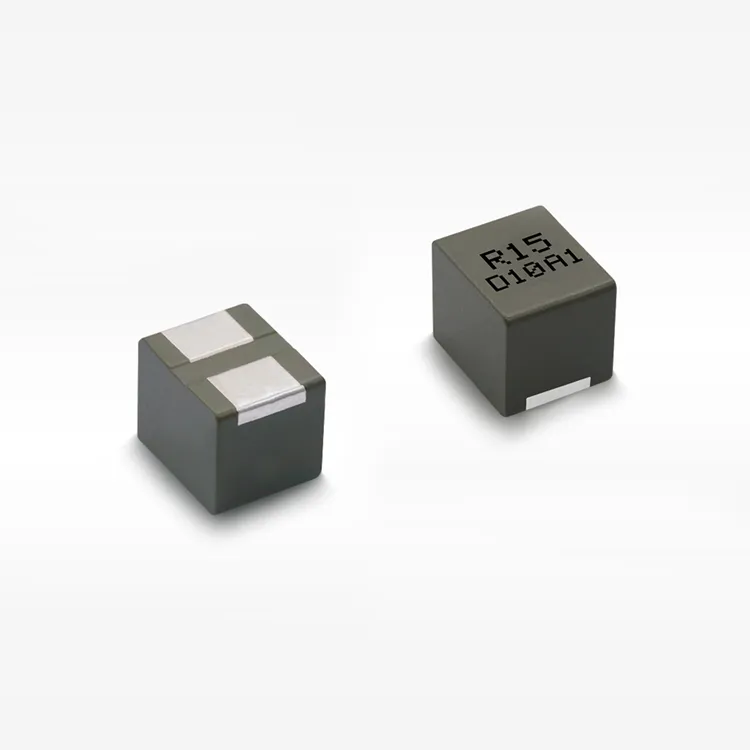

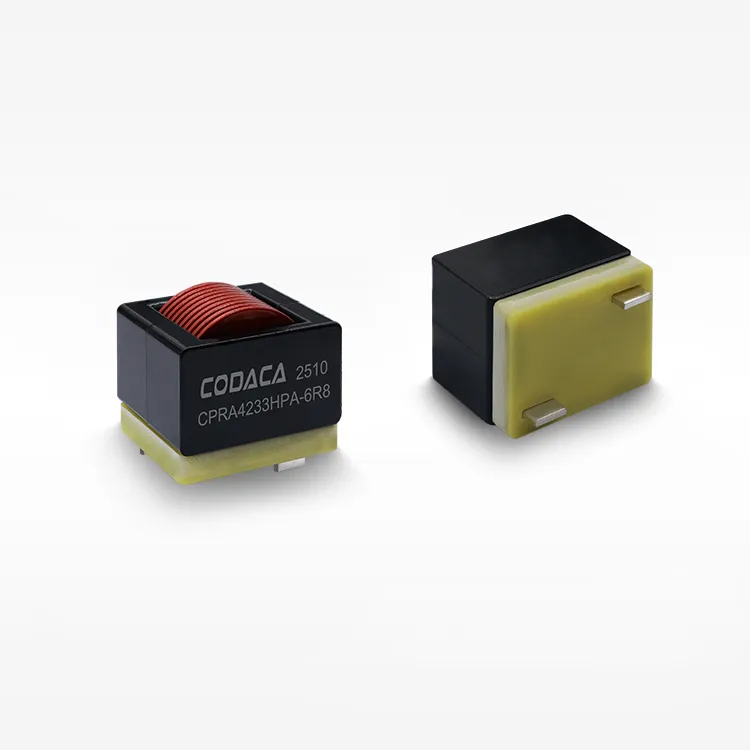

페라이트 전력 인덕터는 고급 제조 기술과 소재 공학을 통해 뛰어난 기계적 강도와 장기적인 신뢰성을 자랑하며, 혹독한 환경에서도 오랜 서비스 기간 동안 안정적인 작동을 보장합니다. 페라이트 소재의 세라믹 특성은 기계적 충격, 진동, 열 순환에 대한 내성을 제공하여 다른 자성 소재에서는 손상될 수 있는 상황에서도 견디기 때문에, 기계적 스트레스가 지속되는 자동차, 항공우주, 산업용 애플리케이션에 이상적인 부품입니다. 페라이트 코어 제조에 사용되는 소결 공정은 다공성이 최소화된 밀도 높고 균일한 구조를 형성하여 시간이 지나도 기계적 파손이나 성능 저하를 유발할 수 있는 약점을 제거합니다. 코어 소재와 권선 도체 간의 열팽창 계수를 일치시켜 온도 순환 중 응력이 집중되는 것을 방지함으로써 광범위한 온도 범위에서도 기계적 완전성을 유지합니다. 페라이트 화합물의 화학적 안정성은 부식, 산화 및 환경적 요인으로 인한 열화에 저항하여 부품 수명 동안 일관된 자성 특성을 보장합니다. 고온 폴리머 및 보호 코팅을 사용한 고급 밀봉 기술은 페라이트 전력 인덕터를 습기, 오염물질 및 기계적 손상으로부터 보호하면서도 신뢰성 있는 작동에 필수적인 열 방출 성능을 유지합니다. 와이어 본딩 및 단자 처리 기술은 금도금 접촉부와 스트레스 완화 설계를 활용하여 열 팽창 및 기계적 움직임으로 인한 연결 불량을 방지합니다. 열 순환 시험, 기계적 충격 시험, 가속 노화 검증 등의 품질 관리 절차를 통해 각 페라이트 전력 인덕터가 출하 전에 엄격한 신뢰성 기준을 충족함을 보장합니다. 페라이트 전력 인덕터는 이동 부품이나 소모성 소재가 없어 기계 부품과 관련된 일반적인 고장 모드를 제거하여 수명 기간 동안 무정비 운용이 가능합니다. 자성 안정성 시험을 통해 코어 소재가 수천 번의 열 순환과 장기간 자기장 노출에도 특성을 유지함을 확인하여 시스템 작동에 영향을 줄 수 있는 점진적인 성능 변화를 방지합니다. 소위 '번인(burn-in)' 절차를 통해 초기 고장을 조기에 식별하고 제거함으로써 공급되는 부품이 일관된 장기 신뢰성을 입증할 수 있도록 합니다. 현장 운용 데이터의 통계 분석을 통해 적절히 사양된 페라이트 전력 인덕터의 평균 고장 간 시간(MTBF)이 수십 년에 달함을 확인하여, 부품 고장이 심각한 결과를 초래할 수 있는 핵심 애플리케이션에 대한 신뢰를 제공합니다. 견고한 소재, 첨단 제조 공정, 포괄적인 시험 절차의 조합은 페라이트 전력 인덕터를 요구 조건이 까다로운 전자 애플리케이션을 위한 가장 신뢰할 수 있는 수동 부품 중 하나로 만듭니다.