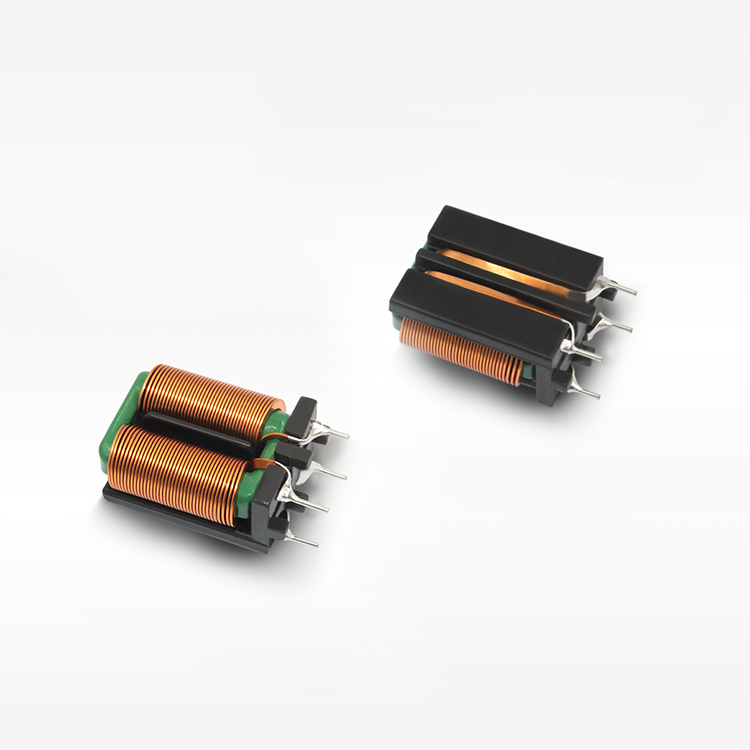

automotive common mode choke factory

It is the automotive common mode choke factory, a modern production base which mainly produces this type of chokes for automotive industry. This device is useful in cars to suppress noise in the electronic system and protect sensitive electronics from being damaged by electromagnetic interference. Here the factory has the most advanced technology now available. Machines for precision winding, automatic testing systems to check out each component's quality, and inspection procedures designed to make sure all products meet our high standards. In addition the factory's products have many uses, they range from engine control units to in-car entertainment systems: wherever - depending on the application and your own territory - we are present ourselves. In this way these various electronic ampere,wata as well as other automotive components can exceed individual requirements for performance and reliability standards.