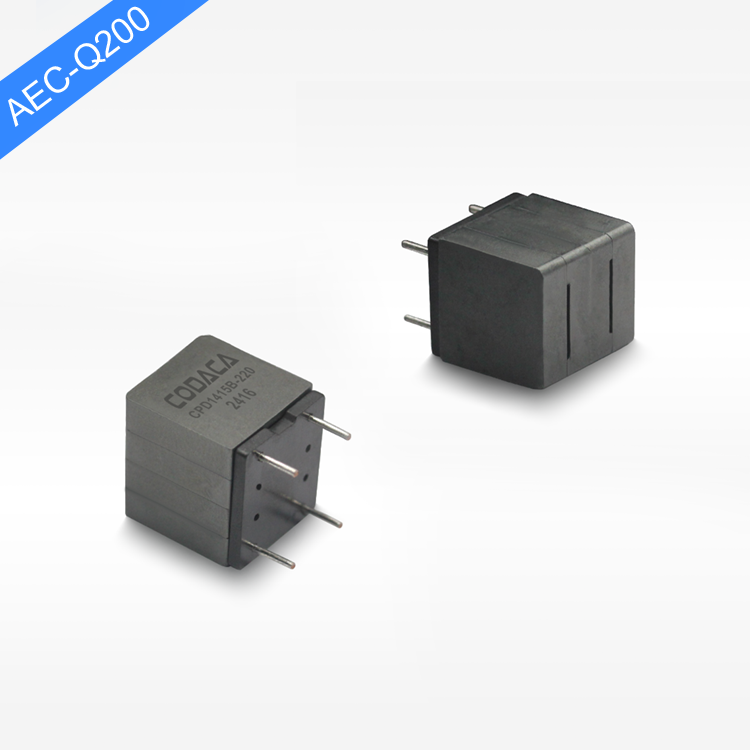

common mode choke for industrial equipment

A common mode choke for industrial equipment represents a critical electromagnetic interference (EMI) filtering component designed to suppress unwanted electrical noise in power and signal lines. This specialized inductive device operates by allowing differential mode signals to pass through while effectively blocking common mode interference that can disrupt sensitive industrial machinery and control systems. The common mode choke for industrial equipment functions as a passive filter that maintains signal integrity while preventing electromagnetic disturbances from propagating throughout electrical networks. Industrial environments present unique challenges with high levels of electrical noise generated by motors, switching power supplies, variable frequency drives, and other heavy machinery. The common mode choke for industrial equipment addresses these challenges through its dual-winding configuration wound around a high-permeability ferrite or iron powder core. This construction creates equal and opposite magnetic fields for differential signals, allowing them to pass unimpeded, while common mode currents produce additive magnetic fields that create high impedance, effectively blocking interference. Key technological features include wide frequency response ranges typically spanning from kilohertz to megahertz bands, high current handling capabilities suitable for industrial power requirements, and robust construction materials that withstand harsh operating conditions including temperature extremes, vibration, and moisture. The common mode choke for industrial equipment incorporates advanced core materials such as nanocrystalline alloys or specialized ferrites that provide superior performance characteristics including low core losses, high saturation flux density, and excellent temperature stability. Applications span across manufacturing automation systems, process control equipment, industrial communication networks, power conversion systems, and motor drive applications where electromagnetic compatibility requirements are stringent. These devices prove essential in meeting international EMC standards while ensuring reliable operation of sensitive electronic components within industrial environments.