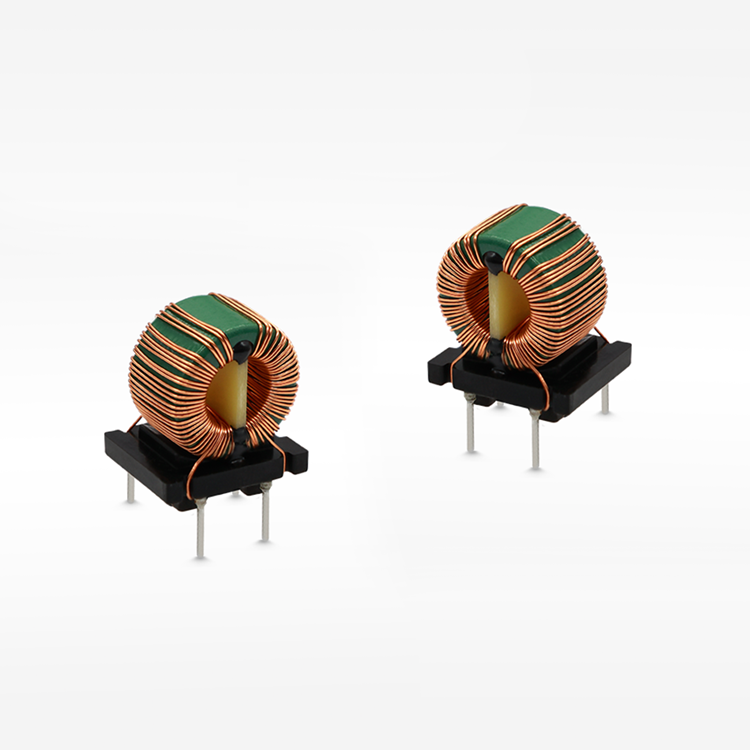

Compact High Current Power Inductor: A Comparison of Materials and Designs

Mn-Zn Ferrite: High Permeability and Frequency Response

Mn-Zn ferrite is highly regarded in the field of inductors due to its high permeability, which facilitates an efficient magnetic flux path. This characteristic translates into improved inductan...

View More