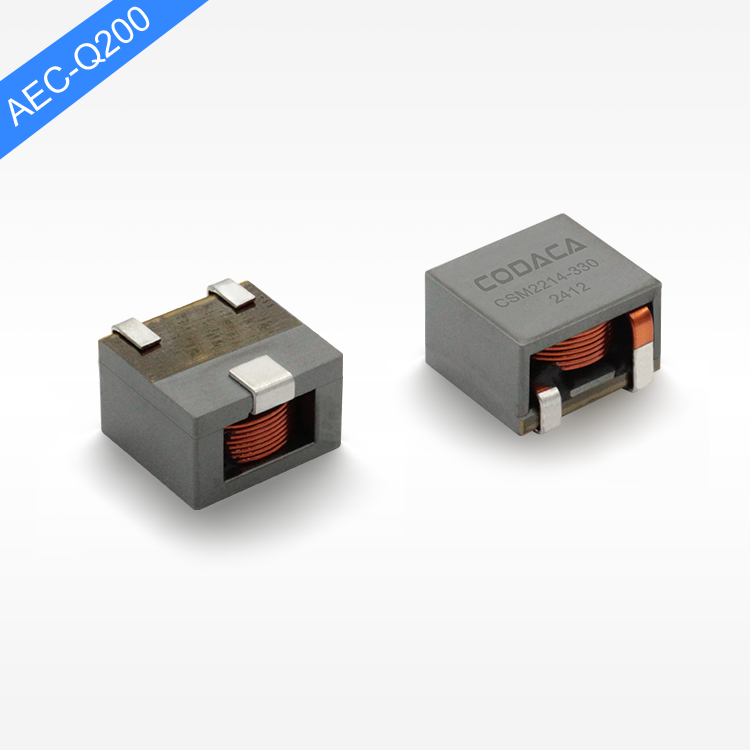

custom magnetic shielded inductor

A custom magnetic shielded inductor represents a sophisticated electromagnetic component engineered to meet specific application requirements while minimizing electromagnetic interference. These specialized inductors incorporate advanced magnetic shielding technology that effectively contains magnetic fields within the component, preventing unwanted interactions with nearby circuits and sensitive electronic equipment. The primary function of a custom magnetic shielded inductor involves storing energy in its magnetic field while filtering, smoothing, or blocking specific frequencies in electronic circuits. Unlike standard inductors, these components feature carefully designed magnetic shields that dramatically reduce external magnetic field emissions and protect against incoming electromagnetic interference. The technological foundation of custom magnetic shielded inductors relies on precision-wound coils combined with high-permeability magnetic materials that form protective barriers around the inductor core. This shielding mechanism utilizes ferrite materials, mu-metal, or other specialized magnetic alloys that redirect magnetic flux lines away from sensitive components. Manufacturing processes involve precise winding techniques, controlled core geometries, and optimized magnetic path designs that maximize inductance while minimizing losses. Custom magnetic shielded inductors find extensive applications across various industries including automotive electronics, medical devices, telecommunications equipment, power supplies, and aerospace systems. In automotive applications, these inductors manage power conversion in electric vehicles, hybrid systems, and advanced driver assistance systems where electromagnetic compatibility is crucial. Medical device manufacturers rely on custom magnetic shielded inductors for MRI equipment, patient monitoring systems, and implantable devices where electromagnetic interference could compromise patient safety. Telecommunications infrastructure utilizes these components in base stations, signal processing equipment, and network switches where signal integrity demands superior electromagnetic isolation. The customization aspect allows engineers to specify precise inductance values, current ratings, operating frequencies, and physical dimensions that match exact application requirements, ensuring optimal performance in demanding environments.