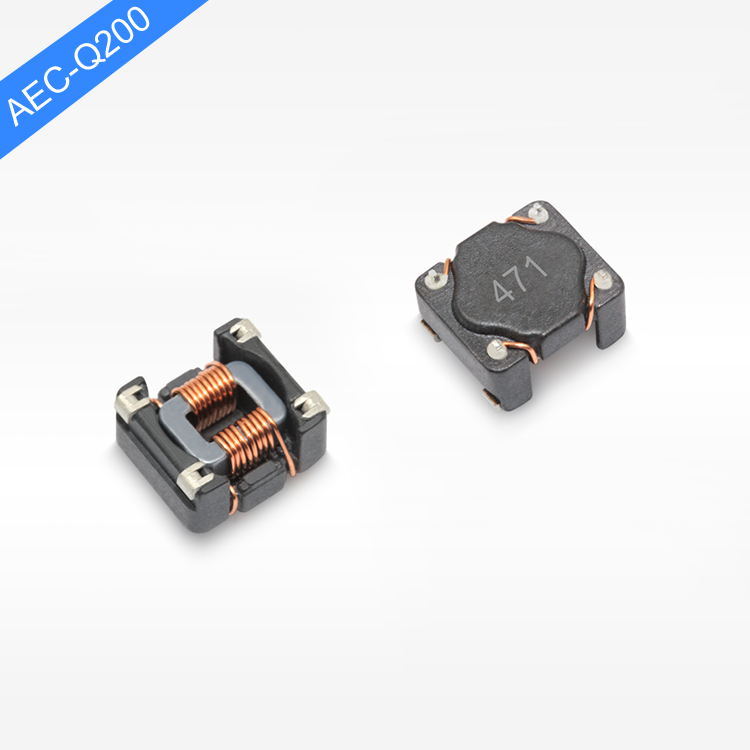

Exceptional Manufacturing Precision and Reliability

The molded shielded inductor achieves outstanding manufacturing precision through advanced automated production processes that deliver consistent electrical and mechanical characteristics across high-volume production runs. This precision manufacturing approach utilizes computer-controlled winding equipment that maintains exact turn counts, wire tension, and layer positioning to ensure predictable inductance values within tight tolerance specifications, typically ±10% or better. The molding process employs precision injection molding techniques with carefully controlled temperature, pressure, and cure time parameters that create uniform material properties and dimensional accuracy. Statistical process control monitors critical parameters throughout production, including core material composition, winding geometry, and final electrical testing, ensuring every molded shielded inductor meets stringent quality standards. Automated optical inspection systems verify physical dimensions, lead coplanarity, and surface finish requirements before packaging. This manufacturing precision translates directly into improved circuit reliability and reduced design margin requirements for end-users. The controlled production environment maintains consistent humidity, temperature, and cleanliness levels that prevent contamination and ensure repeatable material properties. Raw material qualification processes verify core material magnetic properties, wire specifications, and molding compound characteristics before production begins. Traceability systems track each component through every manufacturing step, enabling rapid identification and resolution of any quality issues. Accelerated life testing validates long-term reliability under elevated temperature, humidity, and electrical stress conditions, confirming stable performance over extended operating periods. The precision manufacturing process enables tight coupling between design specifications and actual component performance, reducing prototype iterations and time-to-market for new products. Standardized package dimensions ensure compatibility with automated pick-and-place equipment, facilitating high-volume assembly operations. This manufacturing excellence provides customers with confidence in component availability, consistent performance, and long-term supply chain stability. The investment in advanced manufacturing technology and quality systems demonstrates the commitment to delivering molded shielded inductors that meet the demanding requirements of modern electronic applications while maintaining competitive pricing structures.