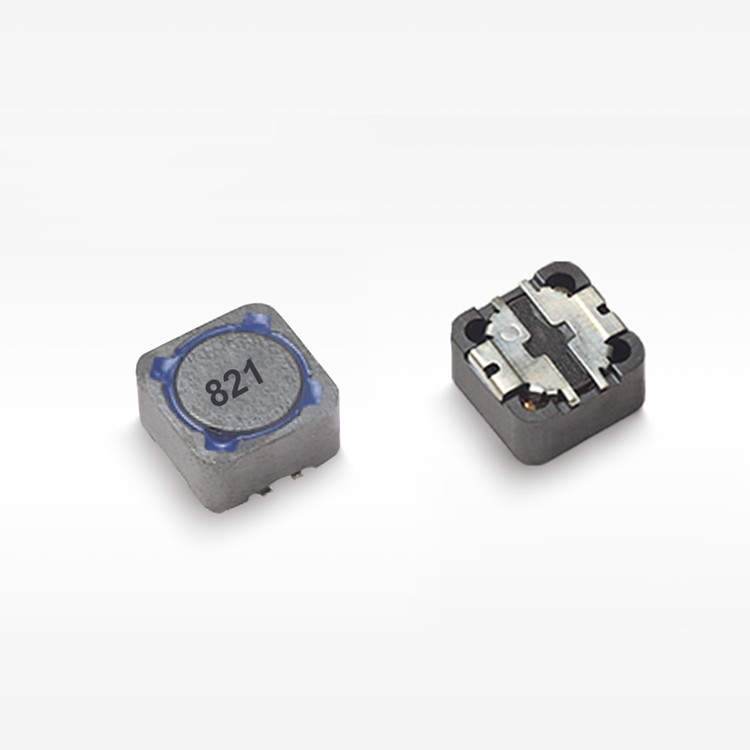

high efficiency smd power inductor

The high efficiency smd power inductor represents a critical component in modern electronic devices, serving as an energy storage and filtering element that manages electrical current flow with exceptional performance. These surface-mount device inductors utilize advanced magnetic core materials and precision winding techniques to achieve superior electrical characteristics while maintaining compact form factors suitable for high-density circuit board layouts. The primary function of the high efficiency smd power inductor involves storing magnetic energy when current flows through its coiled conductor, then releasing this energy to maintain stable current flow during power conversion processes. This fundamental operation makes them indispensable in switching power supplies, DC-DC converters, and voltage regulation circuits. Technologically, these inductors feature low DC resistance values, high saturation current ratings, and minimal core losses, enabling them to operate at elevated frequencies without significant performance degradation. The construction typically employs ferrite or powdered iron cores with carefully optimized permeability characteristics, combined with high-quality copper windings that minimize resistive losses. Advanced manufacturing processes ensure consistent inductance values across production batches while maintaining tight tolerance specifications. Temperature stability remains excellent across operational ranges, with many designs incorporating thermal management features that prevent performance drift under varying environmental conditions. Applications span numerous industries including automotive electronics, telecommunications infrastructure, consumer electronics, industrial automation systems, and renewable energy equipment. In automotive applications, the high efficiency smd power inductor supports engine control modules, infotainment systems, and electric vehicle charging circuits. Telecommunications equipment relies on these components for signal processing, power management, and radio frequency applications. Consumer electronics benefit from their compact size and efficiency in smartphones, tablets, laptops, and gaming devices where space constraints and battery life optimization remain paramount concerns.