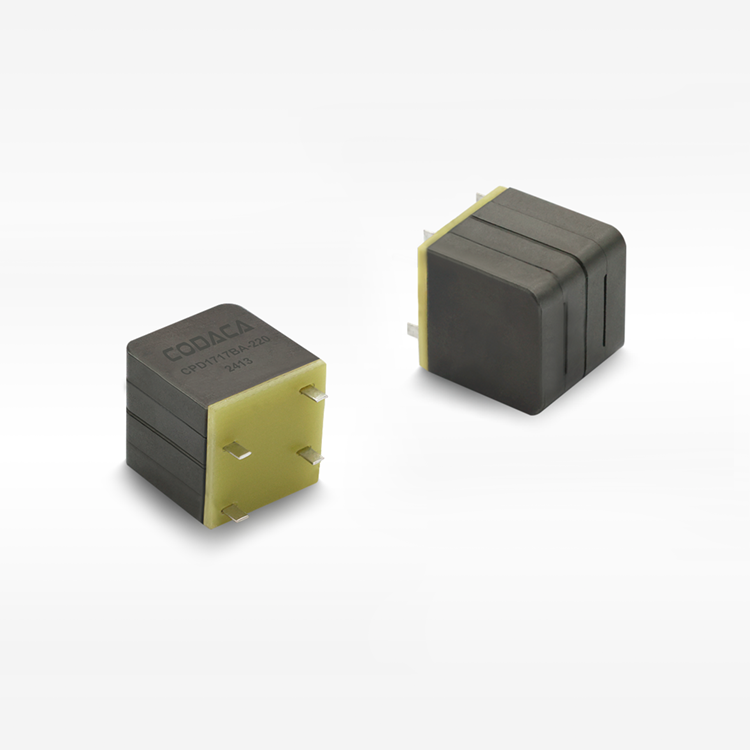

low loss inductor for digital amplifier

The low loss inductor for digital amplifier represents a critical component in modern audio engineering, specifically designed to minimize energy dissipation while maintaining optimal performance in digital audio systems. These specialized inductors serve essential functions within digital amplifier circuits, primarily focusing on power supply filtering, output stage smoothing, and electromagnetic interference suppression. The main technological features of low loss inductor for digital amplifier include advanced core materials such as ferrite or powder iron compositions that significantly reduce hysteresis losses and eddy current effects. These components utilize precision-wound copper conductors with optimized cross-sectional areas to minimize resistance-based power losses. The construction methodology incorporates temperature-stable materials that maintain consistent inductance values across varying operating conditions, ensuring reliable performance throughout the amplifier's operational lifespan. Digital amplifiers require inductors that can handle high-frequency switching operations while maintaining low impedance characteristics. The low loss inductor for digital amplifier addresses these requirements through careful magnetic circuit design that balances inductance stability with minimal core losses. Applications span across professional audio equipment, consumer electronics, automotive sound systems, and high-end audiophile components. In switching power supplies within digital amplifiers, these inductors facilitate efficient energy transfer while reducing thermal generation that could compromise overall system reliability. The frequency response characteristics of low loss inductor for digital amplifier components are specifically tailored to complement pulse-width modulation circuits commonly found in Class D amplifier architectures. Manufacturing processes involve precision winding techniques and quality control measures that ensure consistent electrical parameters across production batches. These inductors contribute to improved signal-to-noise ratios, reduced electromagnetic emissions, and enhanced overall amplifier efficiency, making them indispensable components in contemporary digital audio applications where performance and reliability are paramount considerations.