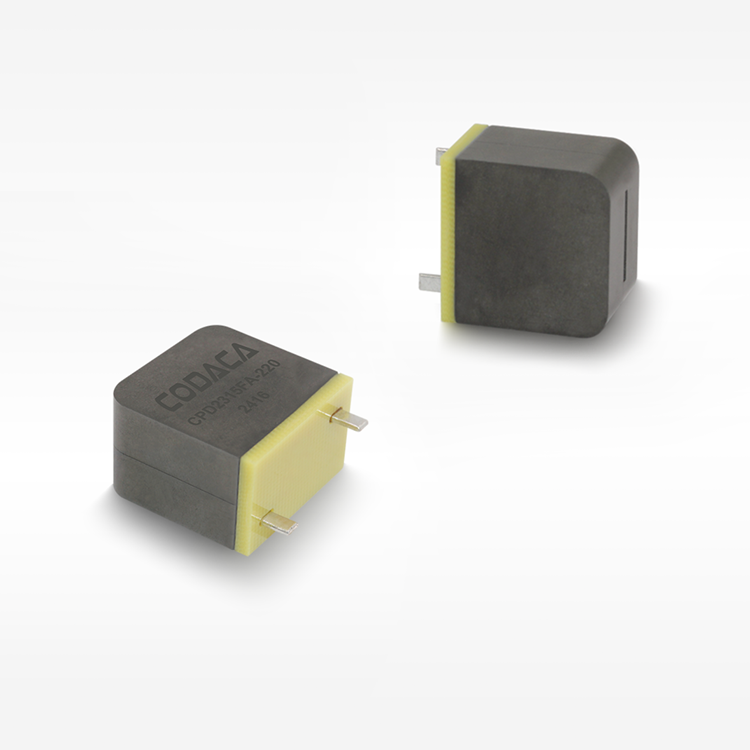

flat wire inductor for digital amplifier

The flat wire inductor for digital amplifier represents a revolutionary advancement in electronic component technology, specifically engineered to meet the demanding requirements of modern digital audio systems. This specialized component utilizes a unique flat wire construction that differs significantly from traditional round wire inductors, offering superior performance characteristics essential for high-fidelity digital amplification applications. The flat wire inductor for digital amplifier serves multiple critical functions within audio circuits, including energy storage, signal filtering, and electromagnetic interference suppression. Its primary role involves managing current flow and voltage regulation, ensuring stable power delivery to digital amplifier circuits while minimizing unwanted noise and distortion. The technological features of the flat wire inductor for digital amplifier include enhanced current-carrying capacity due to the increased surface area of flat wire construction. This design reduces skin effect losses at high frequencies, resulting in improved efficiency and thermal performance. The component typically features precise inductance values ranging from microhenries to millihenries, depending on specific application requirements. Advanced magnetic core materials, such as ferrite or powder iron, provide optimal permeability characteristics while maintaining stability across varying temperature conditions. The flat wire inductor for digital amplifier finds extensive applications in Class D amplifiers, switching power supplies, and digital signal processing circuits. These components are particularly valuable in automotive audio systems, home theater equipment, portable speakers, and professional audio gear where space constraints and efficiency requirements are paramount. The compact form factor of the flat wire inductor for digital amplifier enables designers to create more efficient PCB layouts while achieving superior electrical performance. Manufacturing processes involve precision winding techniques that ensure consistent electrical characteristics and mechanical stability. Quality control measures include inductance tolerance verification, DC resistance testing, and thermal cycling validation to guarantee reliable operation under demanding conditions.