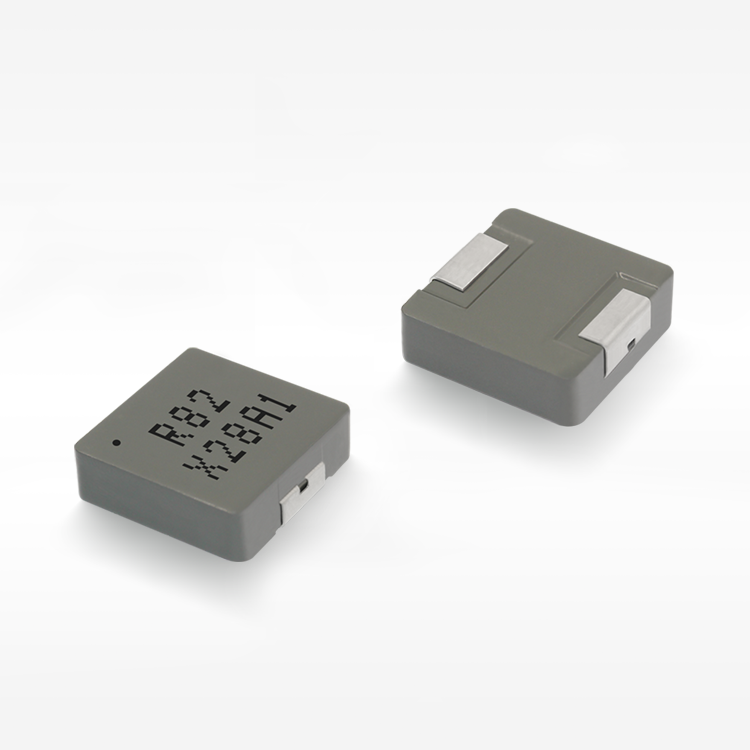

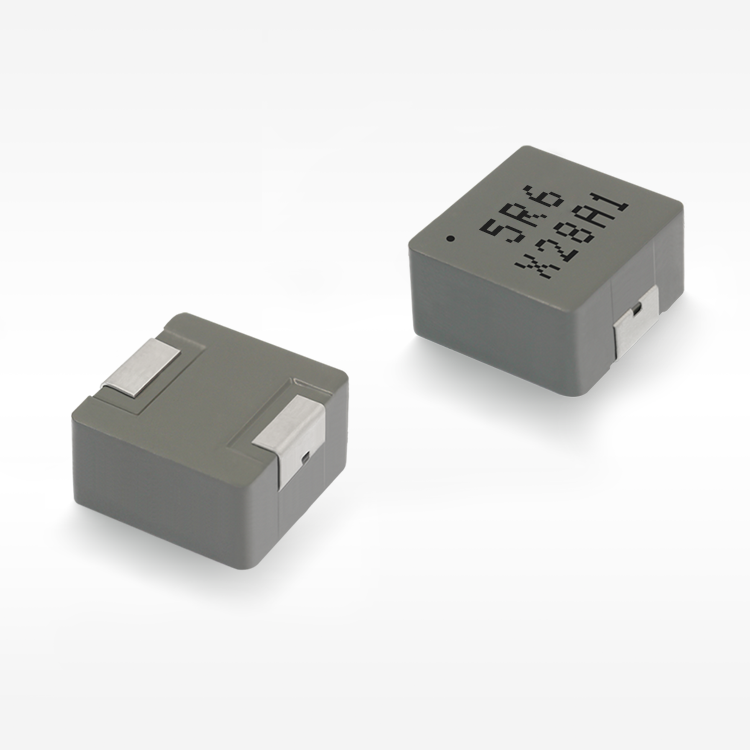

molding power choke for car lighting

The molding power choke for car lighting represents a critical electronic component designed to regulate electrical current and enhance the performance of automotive lighting systems. This specialized inductive device serves as an electromagnetic filter that manages power flow, ensuring stable and consistent operation of various car lighting applications including headlights, taillights, fog lights, and interior illumination systems. The molding power choke for car lighting utilizes advanced ferrite core technology wrapped with precision-wound copper wire, encapsulated in durable molding materials that provide excellent protection against environmental factors such as moisture, vibration, and temperature fluctuations commonly encountered in automotive environments. The primary function of this component involves smoothing electrical current by storing energy in its magnetic field during current peaks and releasing it during valleys, effectively reducing electrical noise and preventing voltage spikes that could damage sensitive lighting circuits. Technologically, the molding power choke for car lighting incorporates high-permeability ferrite cores that maximize inductance while minimizing size and weight constraints crucial for modern vehicle design. The molding process ensures hermetic sealing and mechanical stability, while the carefully engineered wire configuration optimizes impedance characteristics across the frequency spectrum relevant to automotive lighting applications. These components typically operate within voltage ranges from 12V to 24V systems, accommodating both standard passenger vehicles and commercial truck applications. The applications of molding power choke for car lighting extend throughout modern vehicle electrical architectures, including LED driver circuits where they provide essential current regulation, HID ballast systems requiring precise power control, and adaptive lighting systems that demand rapid response characteristics. Additionally, these components play vital roles in electromagnetic interference suppression, ensuring compliance with automotive EMC standards while maintaining optimal lighting performance under various operating conditions.