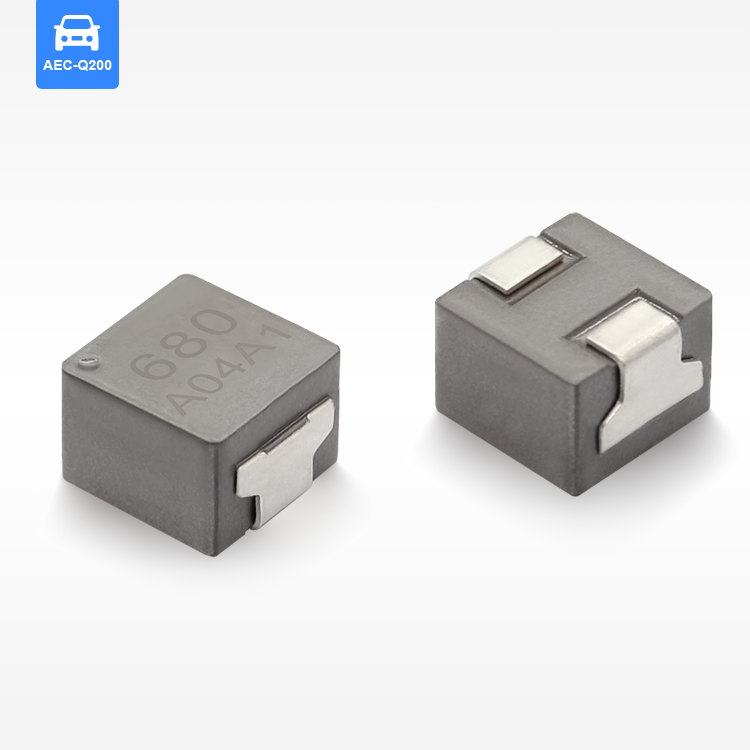

low resistance molding power choke

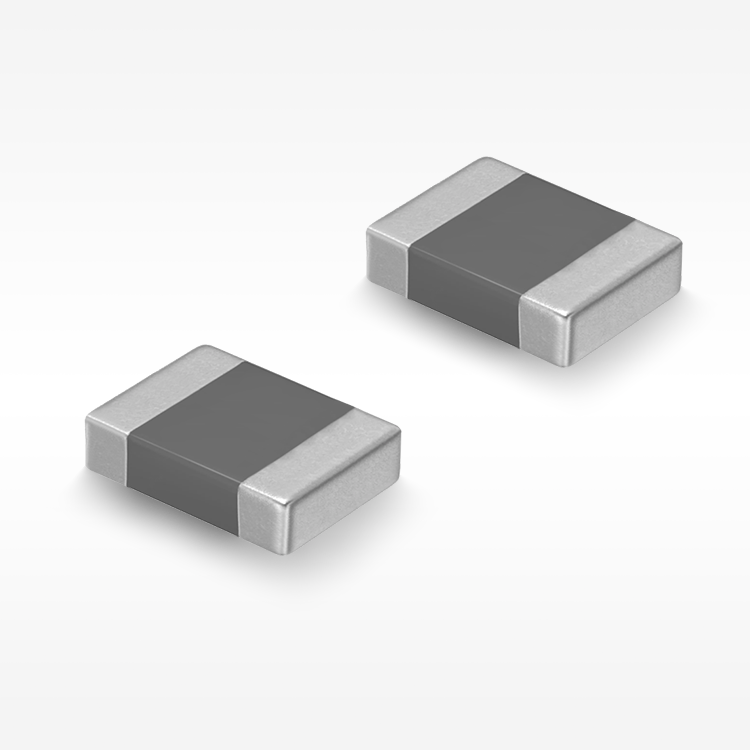

The low resistance molding power choke represents a cutting-edge electromagnetic component designed to deliver superior performance in power conversion and filtering applications. This advanced inductor combines innovative molding technology with optimized electrical characteristics to provide exceptional efficiency and reliability. The low resistance molding power choke features a specially engineered core material and precision winding techniques that minimize electrical losses while maintaining excellent magnetic properties. Its molded construction offers enhanced durability and thermal management capabilities, making it ideal for demanding industrial and commercial environments. The primary function of this component involves energy storage, current smoothing, and electromagnetic interference suppression in various electronic circuits. The low resistance molding power choke operates by storing magnetic energy when current flows through its windings and releasing this energy to maintain continuous current flow during switching operations. This characteristic proves essential in switch-mode power supplies, DC-DC converters, and voltage regulators where consistent power delivery remains critical. The technological features include high-grade ferrite or powder iron cores that provide excellent permeability and low core losses. The molding process encapsulates the entire component in a protective housing that shields against environmental factors such as moisture, dust, and mechanical stress. Advanced winding configurations ensure optimal current distribution and minimize proximity effects that could increase resistance. The low resistance molding power choke finds extensive applications across multiple industries including telecommunications equipment, automotive electronics, renewable energy systems, and consumer electronics. In power management circuits, these components facilitate efficient energy conversion while reducing heat generation and improving overall system reliability. The compact design and standardized form factors enable easy integration into space-constrained applications while maintaining excellent electrical performance characteristics.