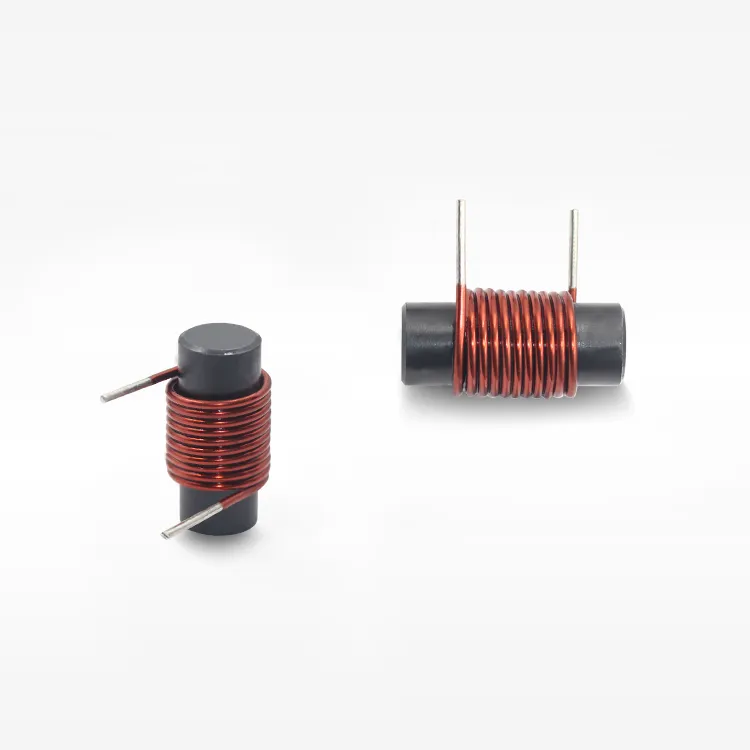

shielded power inductors

Shielded power inductors represent a critical component in modern electronic circuits, designed to store energy in magnetic fields while minimizing electromagnetic interference. These specialized components feature a magnetic core enclosed within a shielding structure, typically composed of ferrite or metal materials, which contains the magnetic flux and prevents it from affecting nearby components. The primary function of shielded power inductors involves filtering, energy storage, and current regulation in power management applications. Unlike their unshielded counterparts, these components utilize advanced magnetic shielding technology to confine electromagnetic fields within the inductor structure, significantly reducing unwanted coupling with adjacent circuit elements. The technological features of shielded power inductors include low DC resistance, high current handling capabilities, and excellent thermal performance characteristics. Their construction incorporates precision-wound copper wire around specially designed cores, with the shielding material providing both mechanical protection and electromagnetic containment. These components operate across wide frequency ranges while maintaining stable inductance values under varying current conditions. Modern shielded power inductors employ sophisticated core materials such as powdered iron, ferrite compounds, and advanced alloys that optimize magnetic permeability while minimizing core losses. The shielding mechanism works by creating a closed magnetic path that directs flux through the core material rather than allowing it to radiate into surrounding space. Applications for shielded power inductors span numerous industries including automotive electronics, telecommunications equipment, computer systems, and renewable energy converters. In switching power supplies, these components smooth output ripple and provide energy storage during switching transitions. DC-DC converters rely heavily on shielded power inductors for efficient voltage regulation and noise suppression. The automotive sector utilizes these components in electric vehicle charging systems, engine management modules, and advanced driver assistance systems where electromagnetic compatibility remains paramount for reliable operation.