The Role of Inductors in Digital Amplifier Performance

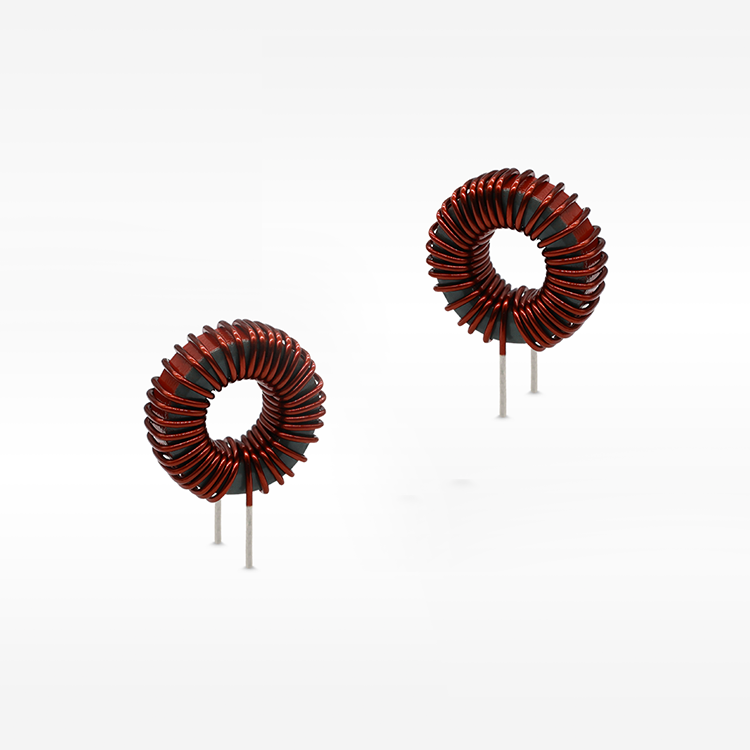

Inductors in amplifier circuits help you manage current flow effectively. They stabilize electrical signals and reduce unwanted noise. By doing so, they enhance the performance of your amplifier. These components also improve energy efficiency, ensur...

View More