בוכנת הספקת חשמל בפלטת תיל לשרת

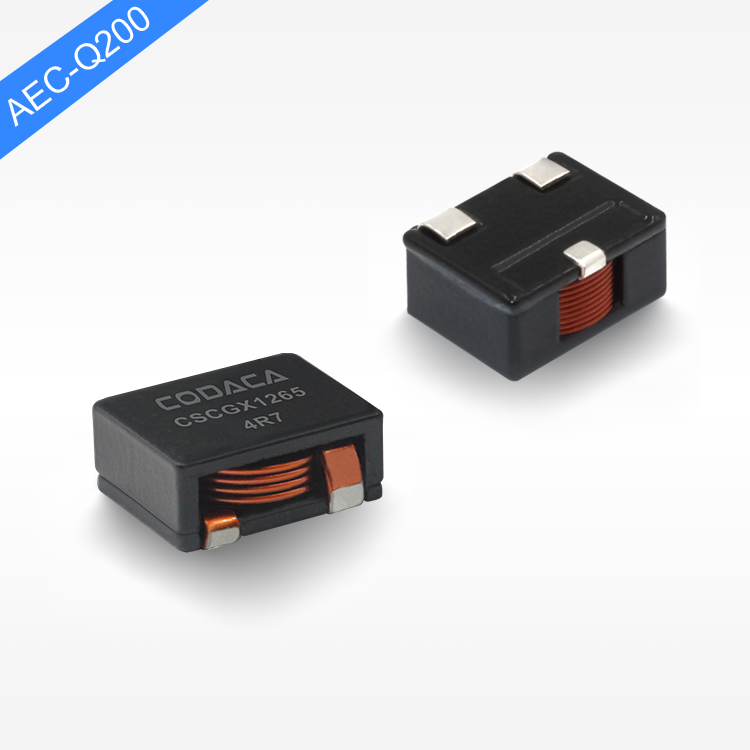

השסתום החשמלי בעל החוט השטוח לספק כוח של שרת הוא רכיב אלקטרומגנטי מתקדם, מעוצב במיוחד כדי לייעל את אספקת הכוח בסביבות حوسبة ביצועים גבוהים. סליל זה מיוחד משתמש בטכנולוגיית מוליך שטוח במקום תצורת חוט עגול מסורתית, ומייצר מאפיינים חשמליים מובילים החיוניים ליישומי שרת מודרניים. השסתום החשמלי בעל החוט השטוח לספק כוח של שרת ממלא מספר פונקציות חשובות בתוך מערכות ניהול כוח, בעיקר אגירת אנרגיה, חלקת זרם והשלטת הפרעות אלקטרומגנטיות. היסודות הטכנולוגיים שלו מבוססים על שליטה מדויקת בשדה מגנטי באמצעות חומרי ליבה וטכניקות כריכה מעוצבות בקפידה. הבנייה של החוט השטוח מאפשרת יכולת העברת זרם משופרת תוך שמירה על גורם צורה קומפקטי, מה שחיוני להגדרות מדף שרת צפופות. חומרי הליבה כוללים בדרך כלל תערובות פריט בחד- חדירות גבוהה או סגסוגות ברזל אבקתי, שנבחרו בגלל יציבות הטמפרטורה שלהם ומאפייניהם עם איבודים נמוכים בתנאי עומס משתנים. תהליכים ייחודיים של ייצור מבטיחים ערכים עקביים של השראות ושינויים מזעריים של סובלנות לאורך סדרות הייצור. השסתום החשמלי בעל החוט השטוח לספק כוח של שרת פועל על ידי אחסון אנרגיה מגנטית במהלך זרימת הזרם ושחרור האנרגיה הזו כדי לשמור על רמות מתח יציבות במהלך מעברי עומס. התנהגות בסיסית זו היא חיונית להגנה על רכיבי שרת רגישים מפני תנודות מתח ולבטיחות פעילות אמינה. היישומים משתרעים על פני ארכיטקטורות שרת שונות, כולל שרתים מסוג בלאד, מערכות המותקות לדלפק, ומجموعות حوسبة צפופות שבהן אופטימיזציה של שטח היא קריטית. הרכיב מתמזג באופן חלק עם ספקי כוח ממתגים, מודולי מכוון מתח, והממיר DC-DC הנפוצים ברשתות הפצת כוח של שרת. דרישות הביצועים כוללות טווחי השראות בתחום המיקרוהנרי עד המיליהנרי, דירוגי זרם בתחומים של מספר אמפרים ועד מאות אמפרים, וטמפרטורות פעולה שמשתרעות מ40- עד 125+ מעלות צלזיוס. פרוטוקולי אימות איכות מוודאים פרמטרים חשמליים, שלמות מכנית ודוכנות סביבתית לאורך כל תהליך הייצור.