דיוק בייצור ואמינות לטווח ארוך

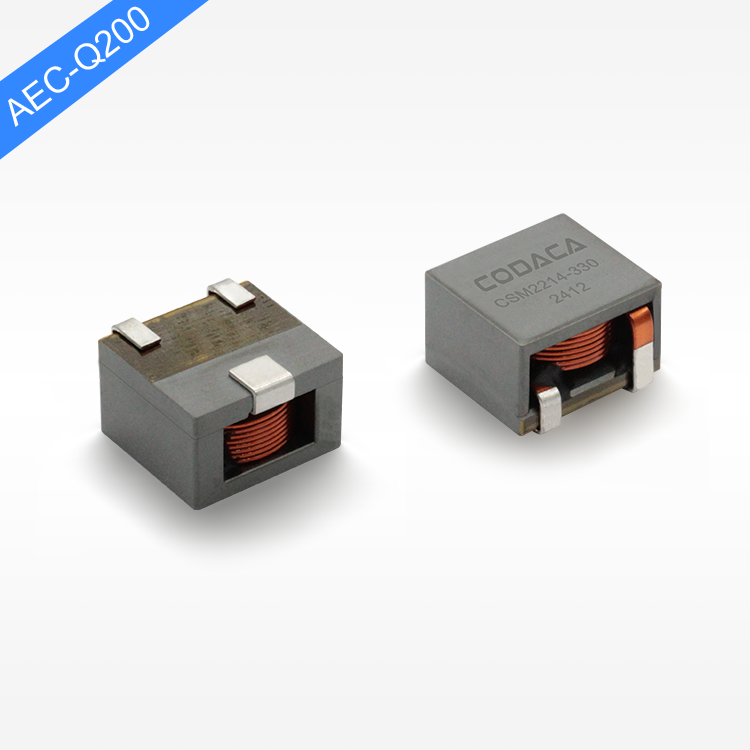

הדיוק ביצור שניתן להשיג באמצעות סלילים מודלריים של חוט שטוח מייצג התקדמות משמעותית לעומת שיטות ייצור מסורתיות של סלילים, ומאפשר פרמטרים חשמליים וمواصفות מכאניות עקביות, המבטיחות תחזות ביצועים של המעגל גם בהיקפי ייצור גדולים. תהליכי wound אוטומטיים המשמשים לבניית חוט שטוח מבטיחים רווח אחיד בין מוליכים, מספר עקומות עקבי ושליטה מדויקת על המימדים, מה שמתורגם ישירות לערכים של השראות בפונצ' טולרנציה וمواصفות של מקדם איכות. דיוק הייצור הזה מונע את השונות בפרמטרים הנלווית לסלילים שמיוצרים ידנית או באופן חצי אוטומטי, ופוחת את הצורך בסינון ובבחירת רכיבים, שמוסיפים עלות וסיבוכות לניהול שרשרת האספקה. תהליך המolding עצמו מספק יתרונות נוספים באיכות על ידי יצירת סביבה אטומה שמהווה שומר על המוליך וחומרי הליבה מפני לחות, זיהום והתחמצנות, שיכולות לפגוע בביצועים החשמליים לאורך זמן. אמינות ארוכת טווח של סלילים מודלריים של חוט שטוח עוקפת את הסוגים_CONVENSIONAL debido to the elimination of mechanical stress points commonly found in wire-wound components where leads exit the core structure. The monolithic molded construction distributes mechanical stresses uniformly throughout the component body, preventing crack initiation and propagation that could lead to electrical failures under thermal cycling or vibration conditions. The material selection for flat wire molded inductors emphasizes compatibility between the conductor, core materials, and molding compounds to minimize coefficient of thermal expansion mismatches that could generate internal stresses during temperature excursions. Quality assurance processes for flat wire molded inductors include comprehensive electrical testing, thermal cycling validation, and mechanical stress testing that ensures consistent performance throughout the specified operating envelope. The traceability systems implemented in flat wire molded inductor manufacturing enable complete documentation of material lots, process parameters, and test results that facilitate rapid issue resolution and continuous improvement initiatives. This manufacturing discipline results in highly reliable components that maintain stable electrical characteristics throughout extended operating periods, reducing warranty costs and customer service requirements for equipment manufacturers who specify these advanced inductors in their designs.