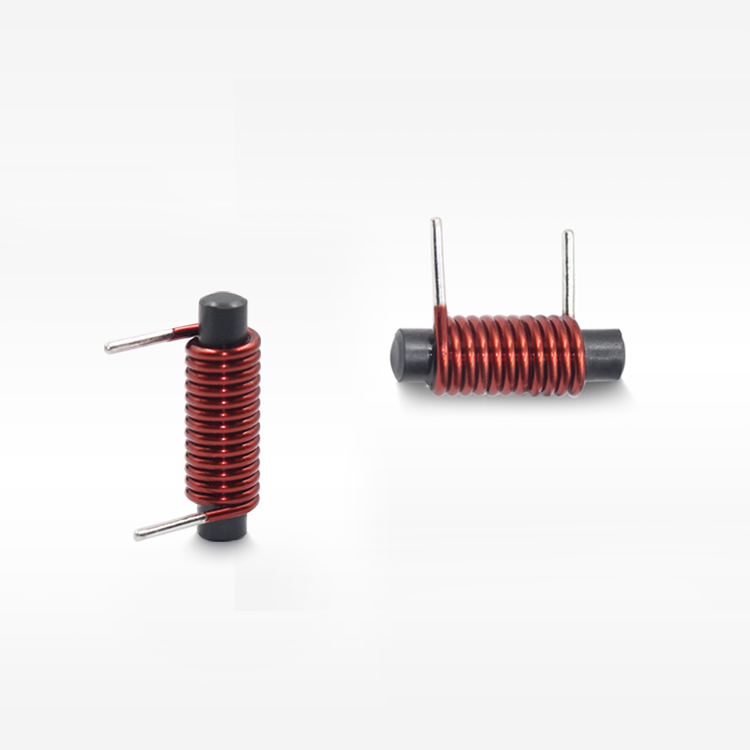

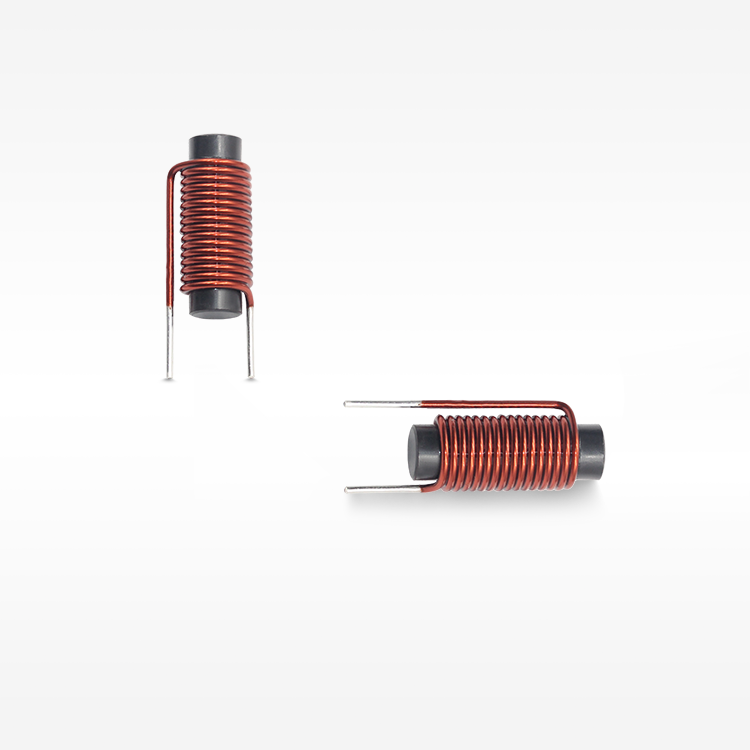

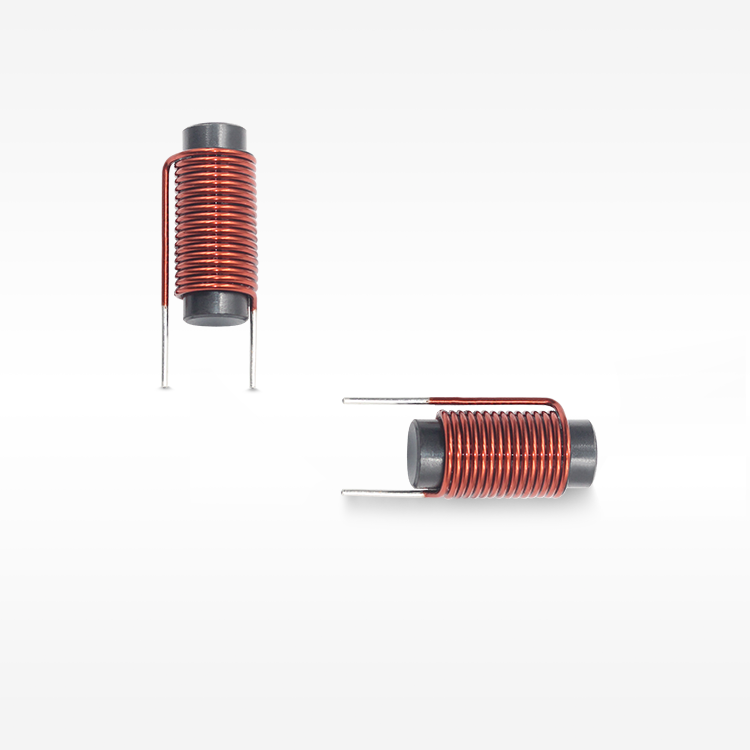

Precision Winding Technology for Enhanced Electrical Characteristics

The customizable rod inductor employs state-of-the-art precision winding technology that ensures exceptional electrical performance through meticulous attention to conductor placement, insulation integrity, and mechanical stability. The winding process utilizes computer-controlled machinery capable of maintaining consistent tension, spacing, and layer distribution throughout the entire coil formation sequence. High-grade copper conductors undergo rigorous quality inspection before winding, ensuring uniform cross-sectional area, surface smoothness, and material purity that directly impacts electrical resistance and current-carrying capacity. The wire selection process considers skin effect phenomena at target operating frequencies, optimizing conductor diameter and configuration to minimize AC resistance and associated power losses. Multi-layer winding techniques distribute turns evenly across the core length, reducing proximity effects between adjacent conductors while maximizing inductance per unit volume. Insulation systems incorporate multiple barrier layers including enamel coatings, film wraps, and impregnation materials that provide superior dielectric strength and thermal endurance. The winding tension control system prevents mechanical stress concentration that could compromise wire integrity or create inconsistent magnetic field distribution. Temperature-rated insulation materials ensure reliable operation across extended thermal ranges, maintaining dielectric properties and preventing breakdown under thermal cycling conditions. The precision winding process enables exact turn count control within plus or minus one percent tolerance, ensuring inductance accuracy that meets demanding application specifications. Layer-to-layer insulation prevents electrical shorts while maintaining minimal additional thickness that could impact overall component dimensions. The termination process utilizes advanced soldering techniques and mechanical securing methods that provide reliable electrical connections resistant to thermal stress and mechanical vibration. Quality verification includes electrical testing of each wound component, measuring inductance, resistance, and insulation integrity before final assembly processes. Advanced winding patterns accommodate special requirements such as center-tapped configurations, multiple windings for transformer applications, and sectioned coils for reduced parasitic capacitance. The manufacturing process maintains detailed traceability records for each customizable rod inductor, documenting materials, process parameters, and test results that support quality assurance and customer-specific documentation requirements.