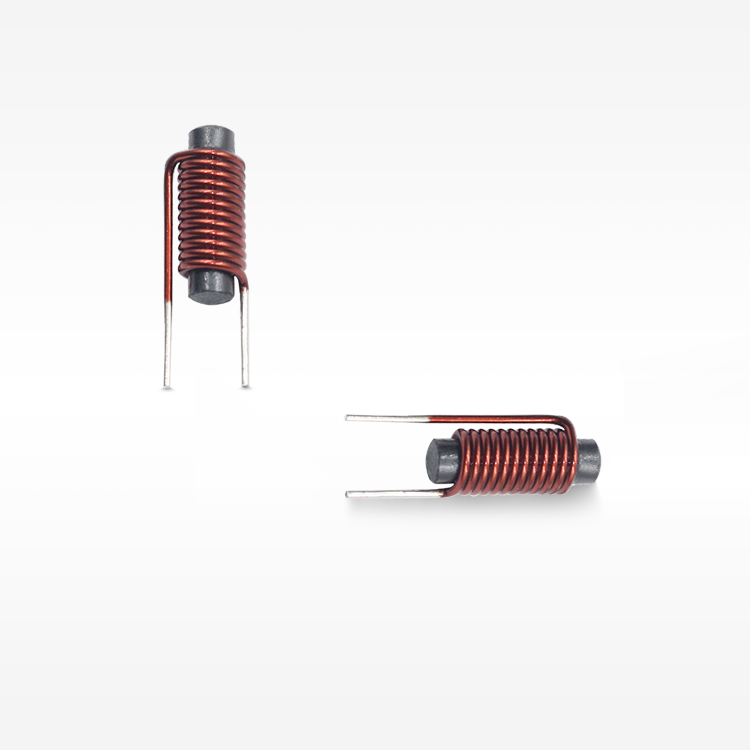

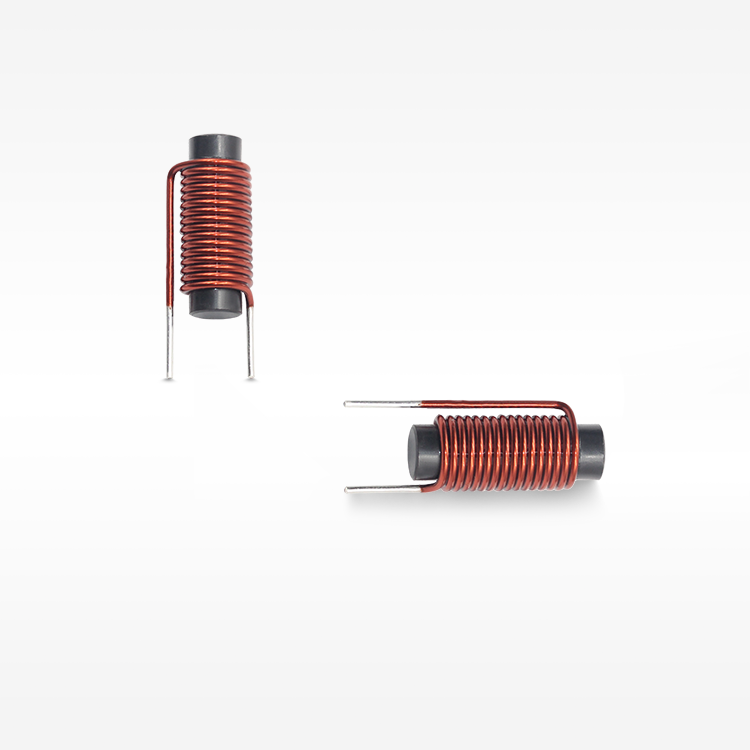

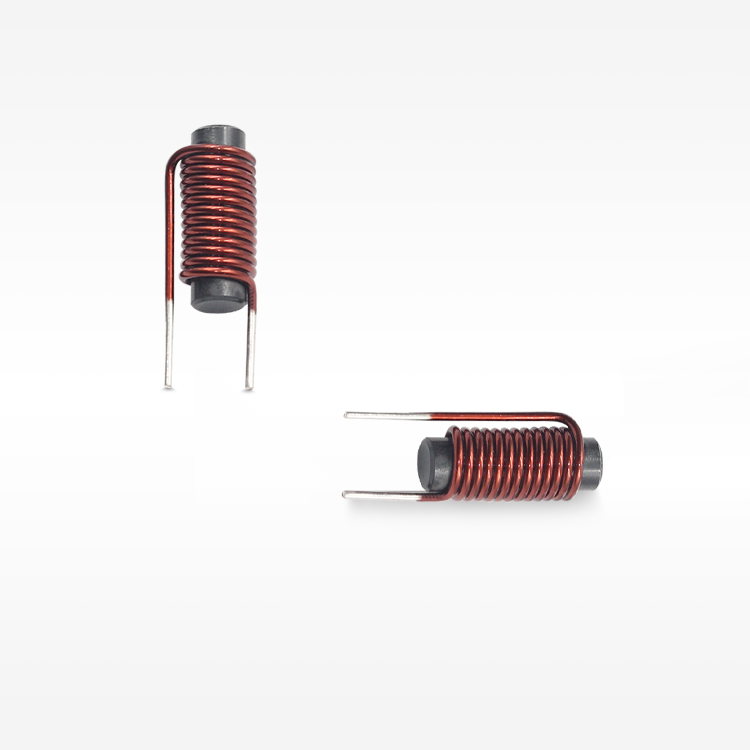

rod inductor

A rod inductor represents a fundamental passive electronic component designed to store energy in its magnetic field when electrical current flows through its conductive windings. This cylindrical-shaped inductor consists of a ferromagnetic rod core wrapped with precisely wound copper wire, creating a concentrated magnetic field that enables efficient energy storage and release. The rod inductor operates on the principle of electromagnetic induction, where the ferrite or iron powder core amplifies the magnetic field strength significantly compared to air-core alternatives. The physical construction features a solid cylindrical core material that provides enhanced permeability, allowing the rod inductor to achieve higher inductance values in compact dimensions. Modern rod inductors incorporate advanced core materials including ferrite compositions, iron powder, and specialized alloys that optimize performance across different frequency ranges. The component's design ensures stable inductance characteristics under varying temperature conditions and current loads, making it suitable for demanding electronic applications. Rod inductors serve multiple critical functions in electronic circuits, including energy storage, current smoothing, noise filtering, and impedance matching. These components excel in power supply circuits where they smooth ripple currents and reduce electromagnetic interference. The rod inductor's ability to maintain consistent performance across wide frequency bands makes it invaluable for RF applications, switching power supplies, and audio equipment. Manufacturing processes involve precision winding techniques that ensure uniform wire spacing and optimal coupling between the conductor and core material. Quality rod inductors feature consistent electrical parameters, low resistance values, and excellent thermal stability. The component's robust construction withstands mechanical stress, temperature fluctuations, and electrical surges commonly encountered in industrial environments. Advanced rod inductor designs incorporate specialized coatings and encapsulation materials that protect against moisture, corrosion, and environmental contaminants, ensuring reliable long-term operation in challenging conditions.