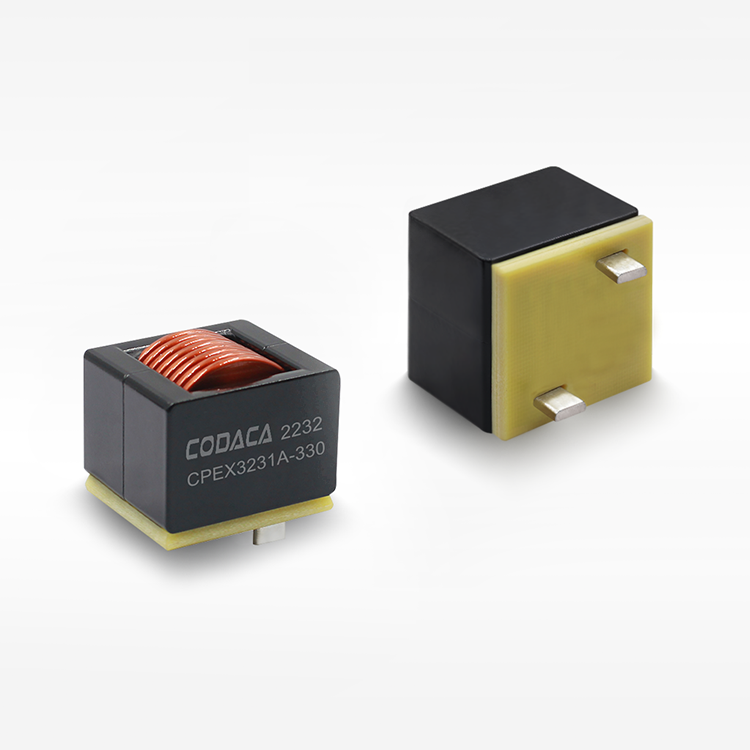

flat wire high current inductor for automotive electronics

The flat wire high current inductor for automotive electronics represents a revolutionary advancement in electromagnetic component technology, specifically engineered to meet the demanding requirements of modern vehicle electrical systems. This innovative component utilizes flat wire construction instead of traditional round wire, enabling superior electrical performance and thermal management capabilities that are essential for automotive applications. The flat wire high current inductor for automotive electronics serves multiple critical functions within vehicle power management systems, including energy storage, current filtering, and electromagnetic interference suppression. Its primary technological feature lies in the flat wire design, which significantly increases the packing density within the inductor core while reducing copper losses through improved conductor utilization. This design approach allows the flat wire high current inductor for automotive electronics to handle substantially higher current levels compared to conventional round wire inductors of similar size. The flat configuration provides enhanced heat dissipation properties, crucial for automotive environments where thermal management directly impacts component reliability and longevity. Advanced materials integration, including high-permeability magnetic cores and specialized insulation systems, further enhances the performance characteristics of the flat wire high current inductor for automotive electronics. These components find extensive applications across various automotive systems, including electric vehicle powertrains, hybrid vehicle energy management systems, advanced driver assistance systems, and infotainment electronics. The flat wire high current inductor for automotive electronics proves particularly valuable in DC-DC converter circuits, where efficient power conversion is paramount for vehicle operation. Additionally, these inductors play vital roles in battery management systems, where precise current control and monitoring are essential for safety and performance optimization.