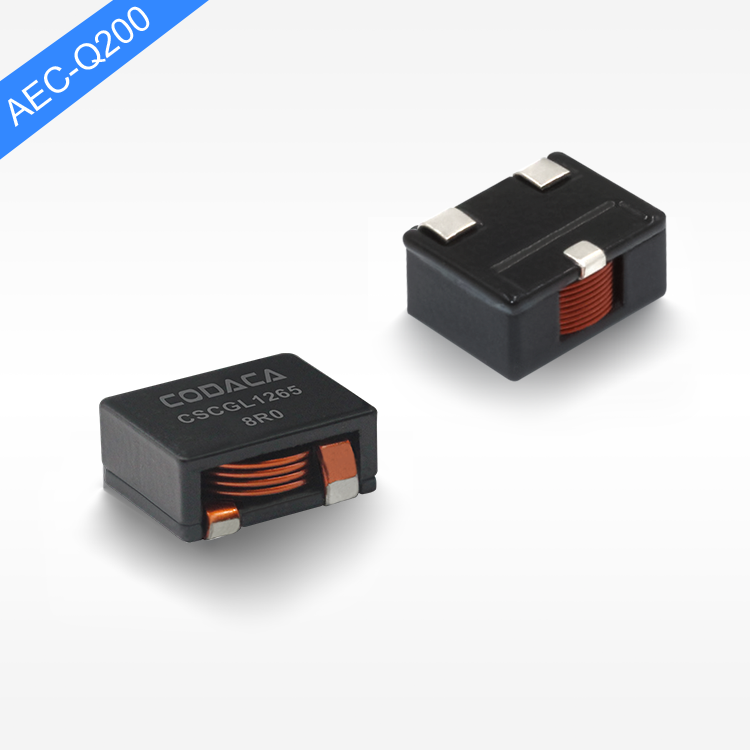

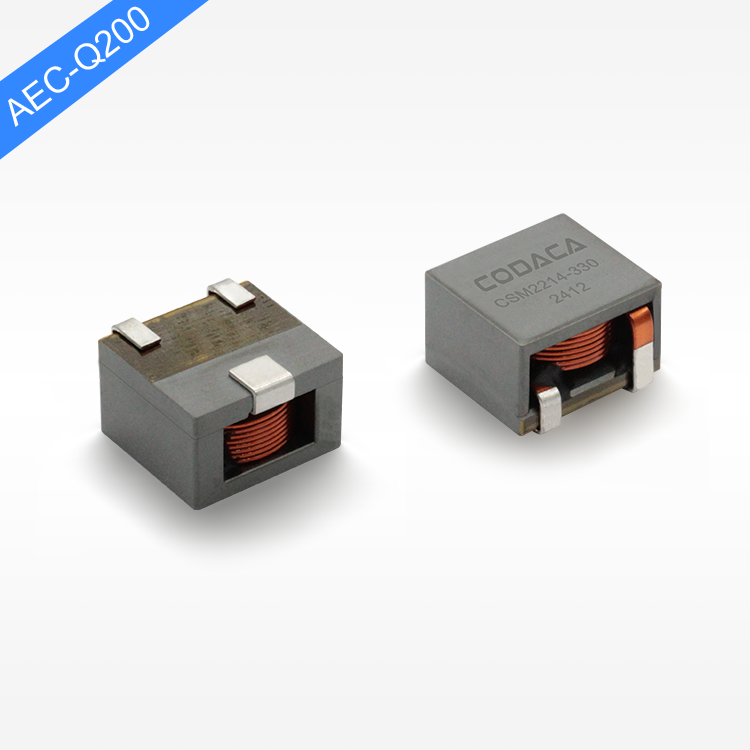

flat wire power inductor supplier

A flat wire power inductor supplier represents a specialized manufacturer that produces cutting-edge electromagnetic components designed to meet the demanding requirements of modern electronic systems. These suppliers focus on creating inductors using flat wire technology, which fundamentally differs from traditional round wire construction methods. The primary function of these components involves storing electromagnetic energy and managing current flow within power conversion circuits, making them essential elements in switching power supplies, DC-DC converters, and various energy management systems. The flat wire power inductor supplier employs advanced manufacturing techniques to create components that deliver superior electrical performance while maintaining compact form factors. These inductors utilize flat rectangular wire windings instead of conventional round conductors, resulting in improved efficiency and thermal management capabilities. The technological features include enhanced current handling capacity, reduced DC resistance, and better heat dissipation properties compared to traditional round wire alternatives. Manufacturing processes involve precision winding techniques, high-quality magnetic core materials, and stringent quality control measures to ensure consistent performance across production batches. Applications span across numerous industries including automotive electronics, telecommunications infrastructure, renewable energy systems, industrial automation equipment, and consumer electronics. The flat wire power inductor supplier serves critical roles in electric vehicle charging systems, solar power inverters, LED lighting drivers, and high-frequency switching circuits. These components enable engineers to design more efficient power systems while reducing overall system size and weight. Quality assurance protocols ensure each inductor meets strict electrical specifications including inductance tolerance, current rating, and temperature coefficient requirements. Advanced testing procedures validate performance under various operating conditions, ensuring reliability in demanding applications. The supplier network provides comprehensive technical support, helping customers select appropriate components for specific design requirements and offering customization options for unique applications.