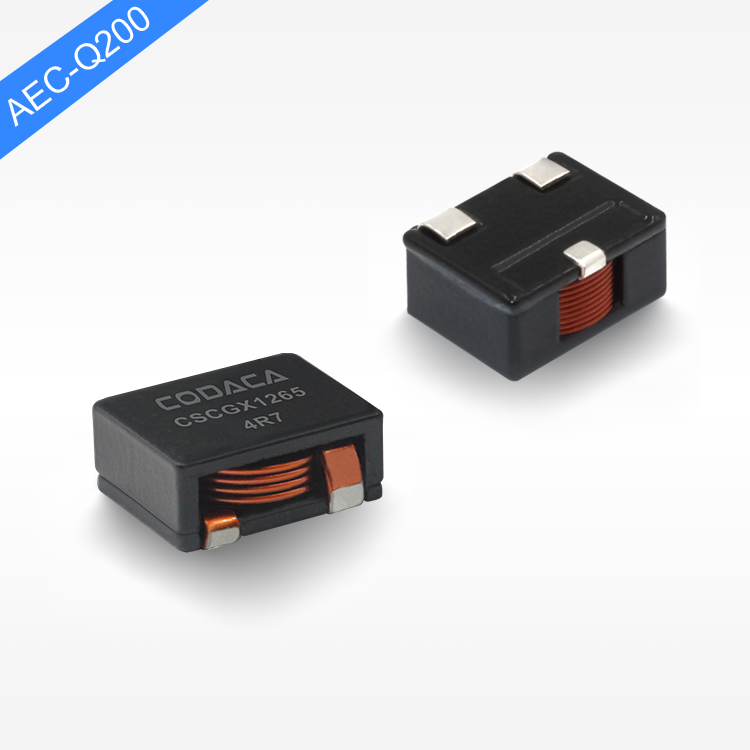

flat wire power choke for server power supply

The flat wire power choke for server power supply represents a cutting-edge electromagnetic component engineered to optimize power delivery in high-performance computing environments. This specialized inductor utilizes flattened conductor technology instead of traditional round wire configurations, creating superior electrical characteristics essential for modern server applications. The flat wire power choke for server power supply serves multiple critical functions within power management systems, primarily focusing on energy storage, current smoothing, and electromagnetic interference suppression. Its primary technological foundation relies on precise magnetic field control through carefully designed core materials and winding techniques. The flat wire construction enables enhanced current-carrying capacity while maintaining compact form factors crucial for dense server rack configurations. Core materials typically incorporate high-permeability ferrite compositions or powdered iron alloys, selected for their temperature stability and low-loss characteristics under varying load conditions. Advanced manufacturing processes ensure consistent inductance values and minimal tolerance variations across production batches. The flat wire power choke for server power supply operates by storing magnetic energy during current flow and releasing this energy to maintain steady voltage levels during load transitions. This fundamental behavior proves essential for protecting sensitive server components from voltage fluctuations and ensuring reliable operation. Applications span across various server architectures, including blade servers, rack-mounted systems, and high-density computing clusters where space optimization remains paramount. The component integrates seamlessly with switching power supplies, voltage regulator modules, and DC-DC converters commonly found in server power distribution networks. Performance specifications typically include inductance ranges from microhenries to millihenries, current ratings spanning several amperes to hundreds of amperes, and operating temperatures extending from negative forty to positive one hundred twenty-five degrees Celsius. Quality assurance protocols verify electrical parameters, mechanical integrity, and environmental resilience throughout the manufacturing process.