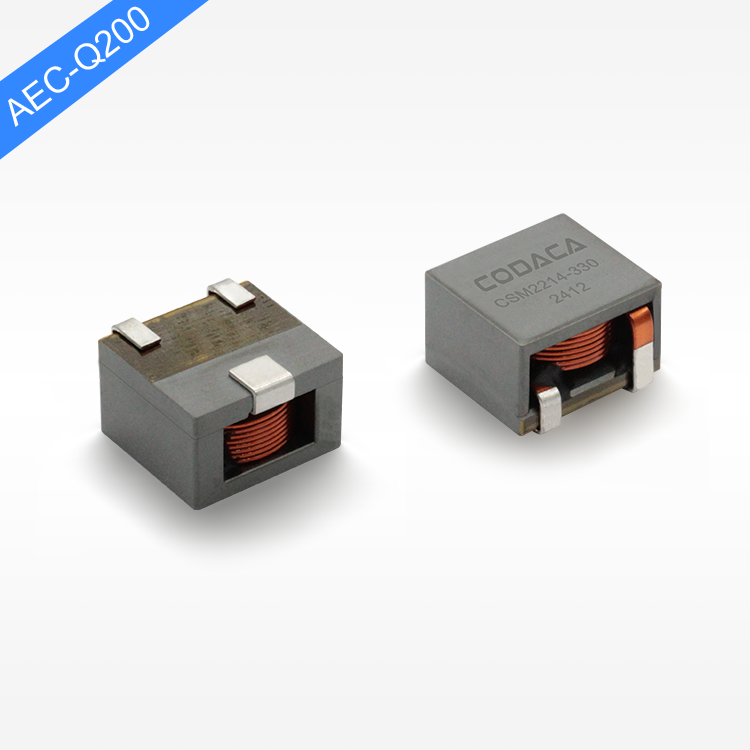

flat wire molded inductor

The flat wire molded inductor represents a revolutionary advancement in electronic component design, combining innovative materials and precision engineering to deliver exceptional performance in modern electronic applications. Unlike traditional round wire inductors, this component utilizes flat copper wire construction that maximizes conductor surface area while minimizing overall footprint. The flat wire molded inductor serves as a critical component in power management circuits, filtering applications, and energy storage systems across various industries. Its primary function involves storing magnetic energy when current flows through the winding, then releasing this energy to maintain circuit stability and reduce electromagnetic interference. The technological features of the flat wire molded inductor include superior current handling capabilities due to increased conductor cross-sectional area, enhanced thermal dissipation properties, and improved electromagnetic shielding characteristics. The molding process encapsulates the flat wire coil in high-grade ferrite or composite materials, providing excellent mechanical protection and environmental resistance. This construction method ensures consistent electrical properties while maintaining compact dimensions essential for space-constrained applications. The flat wire molded inductor finds extensive use in automotive electronics, telecommunications equipment, consumer electronics, and industrial automation systems. In automotive applications, these inductors support power conversion in electric vehicle charging systems, LED lighting circuits, and advanced driver assistance systems. Telecommunications infrastructure relies on flat wire molded inductors for signal conditioning, power supply filtering, and RF applications where high frequency performance is crucial. Consumer electronics benefit from the compact size and efficient operation of flat wire molded inductors in smartphones, tablets, and portable devices where battery life and thermal management are paramount considerations.