Molding Power Chokes vs. Traditional Chokes: What's the Difference?

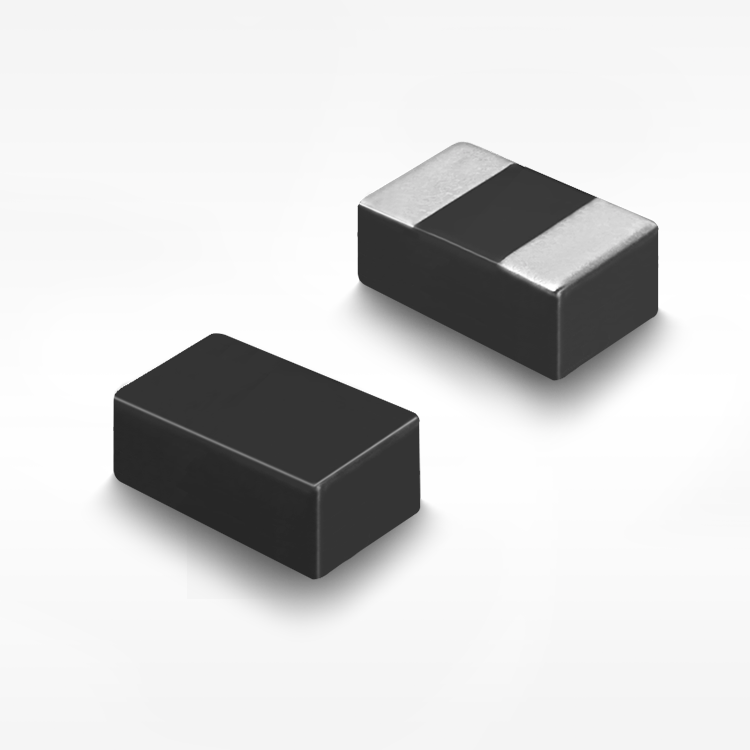

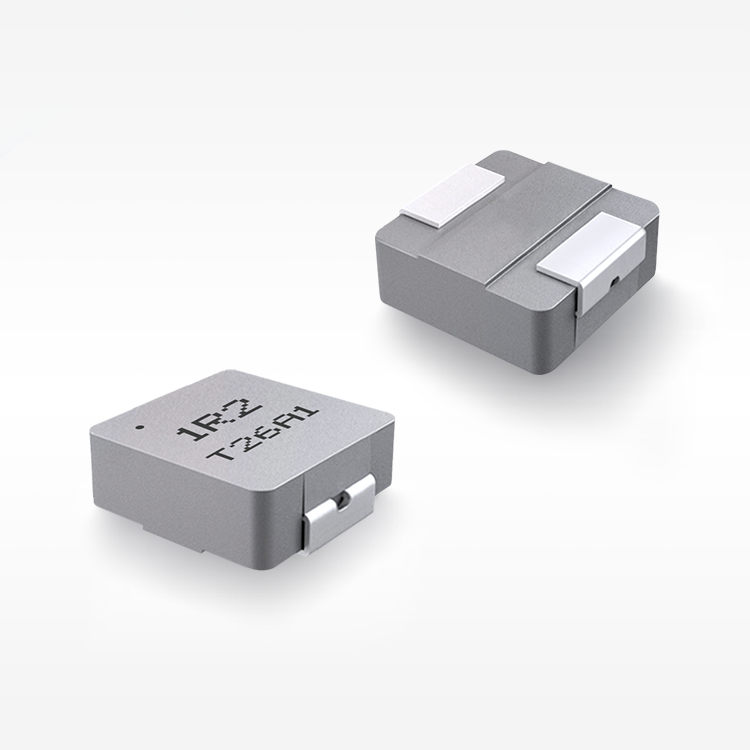

Core Construction Differences Between Molding Power Chokes and Traditional Chokes

Materials: Ferrite vs. Iron Core Composition

The primary difference between molding power chokes and traditional chokes lies in the material composition of their cores...

View More