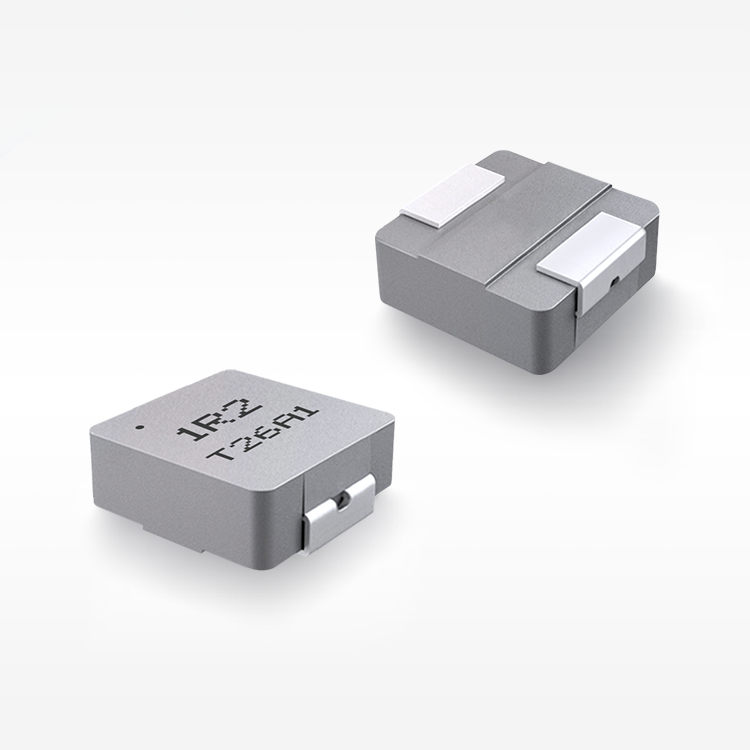

molding power chokes manufacturing

Molded power chokes production is a sophisticated process, putting the development of excellent components (inductive components) used in electronic devices. These chokes act as indispensable subsystems for power supplies and a variety of electronic circuits, its main role being to filter or stabilize electrical current. Technological characteristics of molding power chokes are that they provide high saturation current, low resistance and their compact size improves their performance quality. This power supply application is made on the basis of advanced electronic materials, using precision engineering to achieve absolute ruggedness and reliability. The idea is to ensure power supply which gives good signal quality. With precise temperature control built in too, what can you ask for? If you do not need this aspect of the design -Molding Power Chokes find applications across a wide range of fields, ranging from consumer electrics to automobiles and industrial automation where accurate, efficient power management is a must.