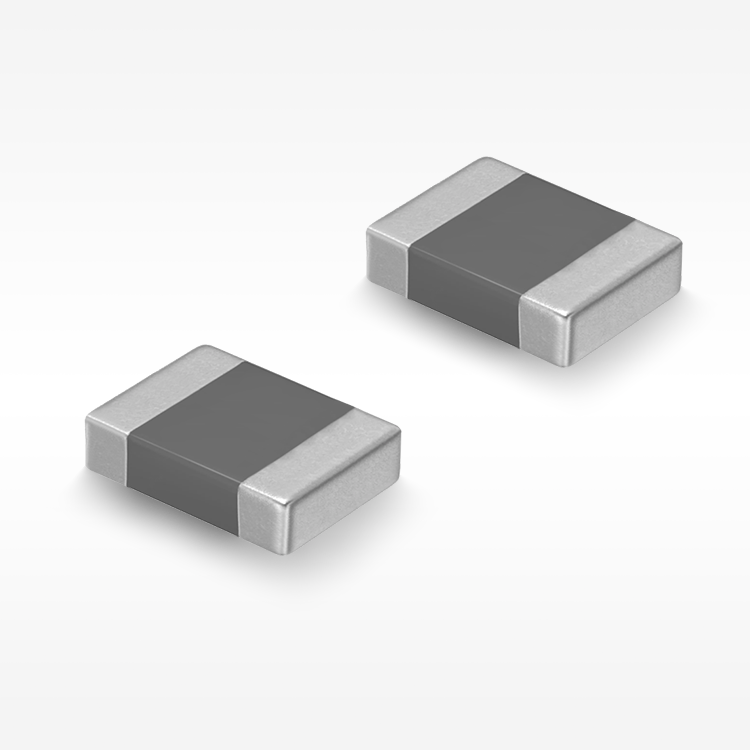

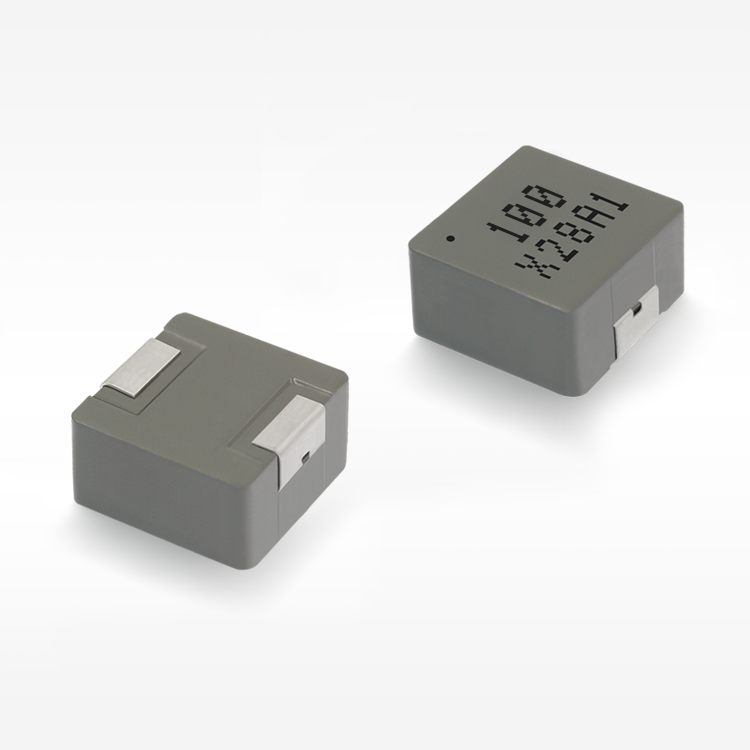

vehicle grade molding power choke

The vehicle grade molding power choke represents a critical component in modern automotive electrical systems, designed to meet the stringent demands of vehicular applications. This specialized inductive component serves as an essential element for power management, electromagnetic interference suppression, and voltage regulation within automotive electronics. The vehicle grade molding power choke is engineered to withstand the harsh operating conditions typical in automotive environments, including extreme temperature variations, vibrations, and electromagnetic disturbances that standard components cannot tolerate. The core functionality of this component centers around its ability to filter unwanted electrical noise while maintaining stable power delivery to sensitive automotive systems. The molding construction provides superior mechanical protection and environmental sealing, ensuring consistent performance throughout the vehicle's operational lifetime. These chokes utilize advanced magnetic core materials and precision winding techniques to achieve optimal inductance values and current handling capabilities. The vehicle grade molding power choke incorporates sophisticated thermal management features that prevent overheating during high-load conditions, making it suitable for demanding applications such as electric vehicle powertrains, advanced driver assistance systems, and infotainment platforms. The technological architecture includes multi-layer shielding that minimizes electromagnetic interference while maximizing energy efficiency. Applications span across various automotive systems including DC-DC converters, battery management systems, LED lighting circuits, and motor control units. The compact form factor of the vehicle grade molding power choke allows for space-efficient integration into modern vehicle designs where real estate is at a premium. Quality standards for these components exceed typical industrial requirements, incorporating automotive-specific testing protocols and certification processes that ensure reliability in mission-critical applications.