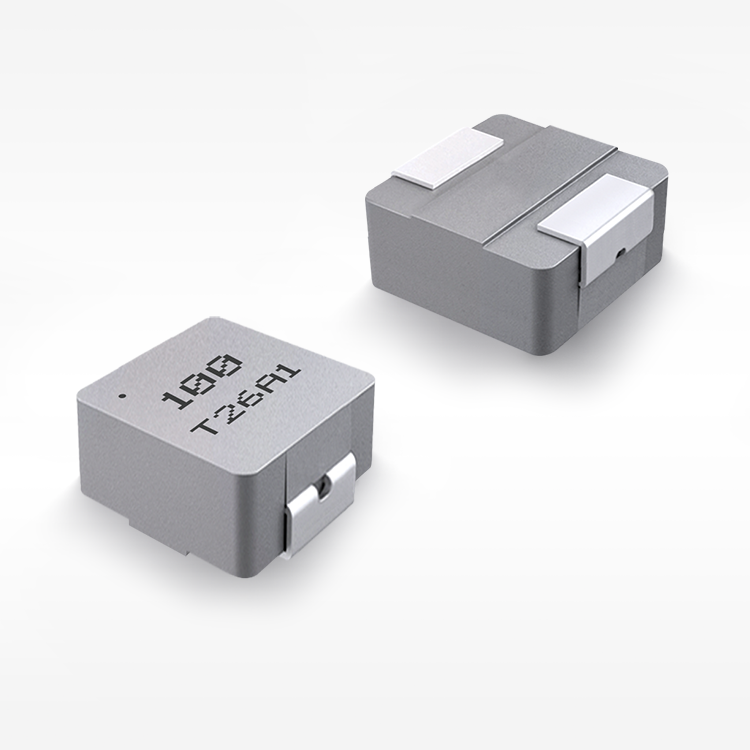

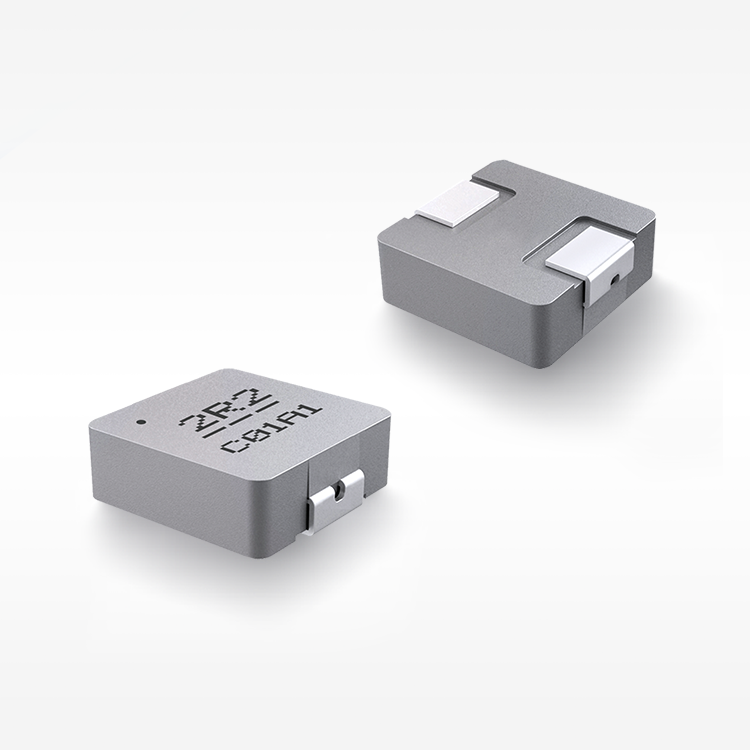

Enhanced Mechanical Durability and Environmental Protection

The high current molding power choke provides unmatched mechanical durability and environmental protection through its innovative molded construction that encapsulates the entire magnetic assembly in a robust protective housing. The molding process creates a seamless, void-free enclosure that shields the internal components from moisture, dust, chemical contaminants, and mechanical damage that could compromise performance or reliability. The specially formulated molding compound exhibits excellent resistance to thermal cycling, mechanical shock, and vibration, making it ideal for automotive, aerospace, and industrial applications where harsh operating conditions are encountered. Advanced adhesion properties ensure permanent bonding between the molding material and internal components, preventing delamination or separation that could lead to component failure. The molded construction provides superior mechanical strength compared to traditional potted or enclosed inductors, withstanding installation stresses and operational forces without damage. Integrated strain relief features protect connection points from mechanical stress, reducing the risk of solder joint failures or wire breakage in high-vibration environments. The environmental sealing capabilities enable operation in humid, corrosive, or contaminated atmospheres without degradation of electrical performance or component integrity. UV resistance properties prevent material degradation when exposed to sunlight or artificial lighting sources, maintaining structural integrity throughout the component lifecycle. The molded design eliminates sharp edges and fragile components, reducing handling damage during assembly and improving manufacturing yields. Additionally, the uniform external surface facilitates automated handling and placement equipment, streamlining production processes and reducing assembly costs. The enhanced durability translates to extended service life and reduced maintenance requirements, providing significant value to customers operating critical systems where component reliability is paramount. This mechanical robustness makes the high current molding power choke particularly suitable for military, medical, and safety-critical applications where failure is not an option.