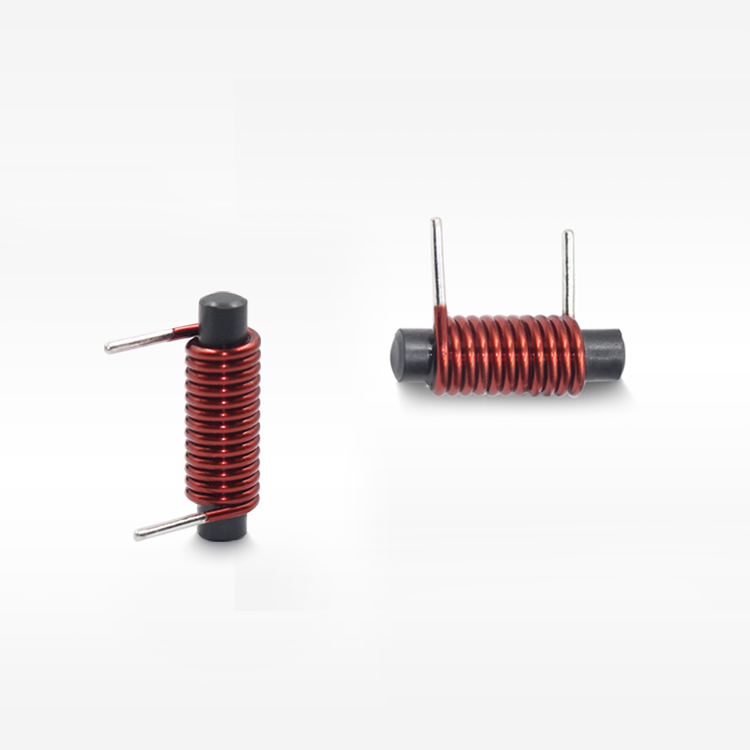

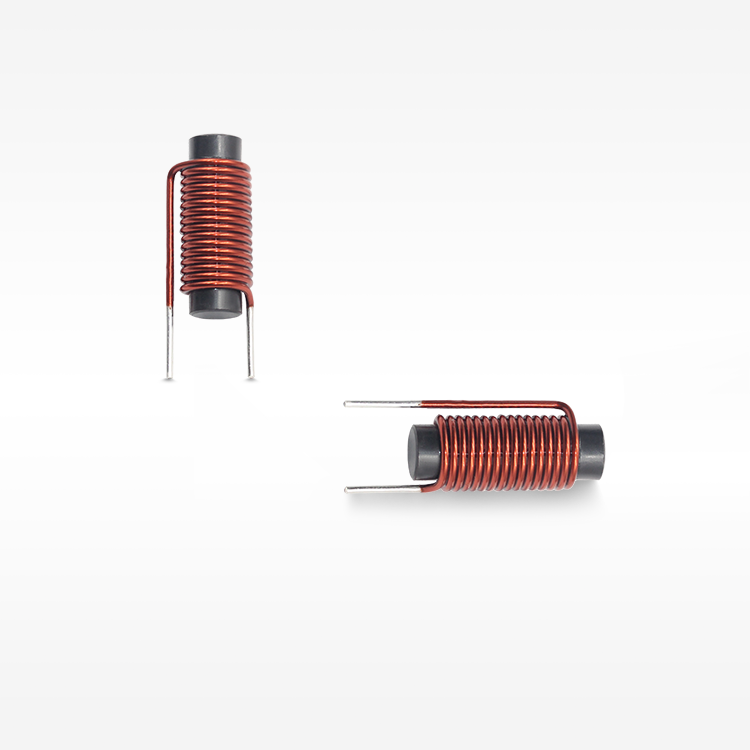

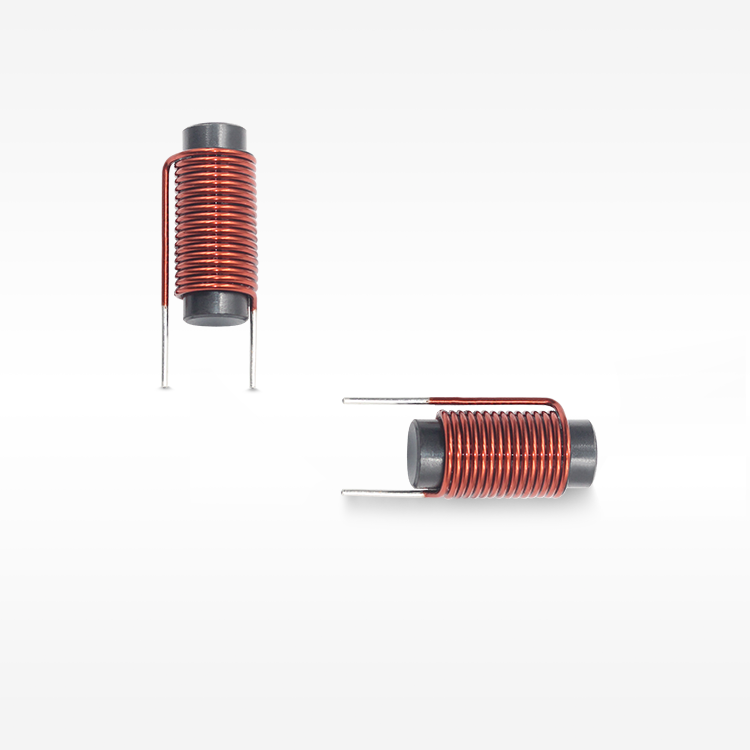

ເຕັກໂນໂລຢີການພັນທີ່ແນ່ນອນສຳລັບຄຸນລັກສະນະໄຟຟ້າທີ່ດີຂຶ້ນ

ເຄື່ອງດັນ rod ທີ່ສາມາດປັບແຕ່ງໄດ້ໃຊ້ເຕັກໂນໂລຢີການລອກລວງຄວາມແມ່ນຍໍາທີ່ທັນສະ ໄຫມ ທີ່ຮັບປະກັນຜົນງານໄຟຟ້າທີ່ພິເສດໂດຍການເອົາໃຈໃສ່ຢ່າງລະອຽດຕໍ່ການວາງຕົວ ນໍາ, ຄວາມສົມບູນແບບຂອງ insulation ແລະຄວາມ ຫມັ້ນ ຄົງທາງກົນຈັກ. ຂະບວນການລອກລວງໃຊ້ເຄື່ອງຈັກທີ່ຄວບຄຸມດ້ວຍຄອມພິວເຕີທີ່ສາມາດຮັກສາຄວາມເຄັ່ງຕຶງ, ການຈັດແບ່ງແລະການແຈກຢາຍຊັ້ນທີ່ສອດຄ່ອງຕະຫຼອດລໍາດັບການສ້າງ coil ທັງ ຫມົດ. ເຄື່ອງ ນໍາ ທອງແດງທີ່ມີຄຸນນະພາບສູງແມ່ນຜ່ານການກວດກາຄຸນນະພາບຢ່າງເຂັ້ມງວດກ່ອນການລອກ, ຮັບປະກັນພື້ນທີ່ຕັດຂ້າມເສັ້ນຜ່າກາງ, ຄວາມລຽບຂອງພື້ນຜິວ, ແລະຄວາມບໍລິສຸດຂອງວັດສະດຸທີ່ສົ່ງຜົນກະທົບໂດຍກົງຕໍ່ຄວາມຕ້ານທານໄຟຟ້າແລະຄວາມສາມາດໃນການຖືກະແສໄຟ ຂະບວນການເລືອກສາຍຖືເຖິງປະກົດການຜົນກະທົບຂອງຜິວ ຫນັງ ໃນຄວາມຖີ່ປະຕິບັດງານເປົ້າ ຫມາຍ, ການປັບປຸງເສັ້ນຜ່າສູນກາງແລະການຕັ້ງຄ່າຂອງຜູ້ ນໍາ ເພື່ອຫຼຸດຜ່ອນການຕໍ່ຕ້ານ AC ແລະການສູນເສຍພະລັງງານທີ່ກ່ຽວຂ້ອງ. ເຕັກນິກການຫຸ້ມຫໍ່ຫຼາຍຊັ້ນແຈກຢາຍການຫັນປ່ຽນຢ່າງເທົ່າທຽມກັນໃນໄລຍະຄວາມຍາວຂອງຫົວໃຈ, ຫຼຸດຜ່ອນຜົນກະທົບຂອງຄວາມໃກ້ຊິດລະຫວ່າງຜູ້ ນໍາ ທີ່ຢູ່ໃກ້ຄຽງໃນຂະນະທີ່ເພີ່ມປະສິດທິພາບຕໍ່ປະລິມານຫົວ ຫນ່ວຍ. ລະບົບປ້ອງກັນຄວາມຮ້ອນປະກອບມີຊັ້ນອຸປະສັກຫຼາຍຊັ້ນລວມທັງການເຄືອບ enamel, ການຫຸ້ມຫໍ່ຮູບເງົາ, ແລະວັດສະດຸທີ່ເຮັດດ້ວຍນ້ ໍາ ມັນທີ່ໃຫ້ຄວາມແຂງແຮງທາງໄຟຟ້າແລະຄວາມທົນທານທາງຄວາມຮ້ອນທີ່ດີເລີດ. ລະບົບຄວບຄຸມຄວາມເຄັ່ງຕຶງການລອກລວງປ້ອງກັນການສຸມຄວາມເຄັ່ງຕຶງກົນຈັກທີ່ອາດຈະເຮັດໃຫ້ຄວາມສົມບູນຂອງສາຍໄຟຕົກລົງຫຼືສ້າງການແຈກຢາຍສະ ຫນາມ ມັກໂນມັດທີ່ບໍ່ສອດຄ່ອງ. ວັດສະດຸ insulation ທີ່ຖືກ ກໍາ ນົດອຸນຫະພູມຮັບປະກັນການເຮັດວຽກທີ່ ຫນ້າ ເຊື່ອຖືໃນໄລຍະຄວາມຮ້ອນທີ່ຍາວນານ, ຮັກສາຄຸນສົມບັດ dielectric ແລະປ້ອງກັນການແຕກຕື່ນໃນສະພາບການ ຫມູນ ວຽນຄວາມຮ້ອນ. ຂະບວນການລອກລວງຄວາມແມ່ນຍໍາຊ່ວຍໃຫ້ການຄວບຄຸມການນັບຊ້ອນຢ່າງແມ່ນຍໍາພາຍໃນຄວາມຍອມຮັບບວກຫຼືລົບ ຫນຶ່ງ ເປີເຊັນ, ຮັບປະກັນຄວາມແມ່ນຍໍາຂອງ inductance ທີ່ຕອບສະ ຫນອງ ຂໍ້ ກໍາ ນົດການ ນໍາ ໃຊ້ທີ່ຕ້ອງການ. ການໂກງແຫນ້ນຈາກຊັ້ນຫາຊັ້ນປ້ອງກັນບໍ່ໃຫ້ໄຟຟ້າສັ້ນໆໃນຂະນະທີ່ຮັກສາຄວາມ ຫນາ ເພີ່ມເຕີມ ຫນ້ອຍ ທີ່ສຸດທີ່ສາມາດສົ່ງຜົນກະທົບຕໍ່ຂະ ຫນາດ ສ່ວນປະກອບທັງ ຫມົດ. ຂະບວນການສິ້ນສຸດການໃຊ້ເຕັກນິກການເຊື່ອມໂລຫະທີ່ກ້າວ ຫນ້າ ແລະວິທີການຕິດຕັ້ງກົນຈັກທີ່ສະ ຫນອງ ການເຊື່ອມຕໍ່ໄຟຟ້າທີ່ ຫນ້າ ເຊື່ອຖືທີ່ທົນທານຕໍ່ຄວາມກົດດັນທາງຄວາມຮ້ອນແລະຄວາມສັ່ນສະເທືອນກົນຈັກ. ການກວດສອບຄຸນນະພາບປະກອບມີການທົດສອບໄຟຟ້າຂອງແຕ່ລະສ່ວນປະກອບຮອຍ, ການວັດແທກຄວາມເຂັ້ມແຂງ, ຄວາມຕ້ານທານ, ແລະຄວາມສົມບູນແບບຂອງ insulation ກ່ອນຂັ້ນຕອນການປະກອບສຸດທ້າຍ. ຮູບແບບການລອກລວງທີ່ກ້າວ ຫນ້າ ເຫມາະ ສົມກັບຄວາມຕ້ອງການພິເສດເຊັ່ນ: ການຕັ້ງຄ່າທີ່ຕິດຢູ່ສູນກາງ, ການລອກລວງຫຼາຍໆຢ່າງ ສໍາ ລັບການ ນໍາ ໃຊ້ເຄື່ອງປ່ຽນ, ແລະສາຍລວດທີ່ຖືກຕັດອອກ ສໍາ ລັບຄວາມສາມາດຂອງ parasitic ທີ່ຫຼຸດລົງ. ຂະບວນການຜະລິດຮັກສາບັນທຶກການຕິດຕາມຢ່າງລະອຽດ ສໍາ ລັບແຕ່ລະເຄື່ອງດຶງດູດ rod ທີ່ສາມາດປັບແຕ່ງໄດ້, ວັດສະດຸການບັນທຶກ, ຕົວວັດແທກຂະບວນການ, ແລະຜົນການທົດສອບທີ່ສະ ຫນັບ ສະ ຫນູນ ຄວາມ ຫມັ້ນ ໃຈດ້ານຄຸນນະພາບແລະຄວາມຕ້ອງການເອກະສານສະເພາະຂອງລູກຄ້າ.