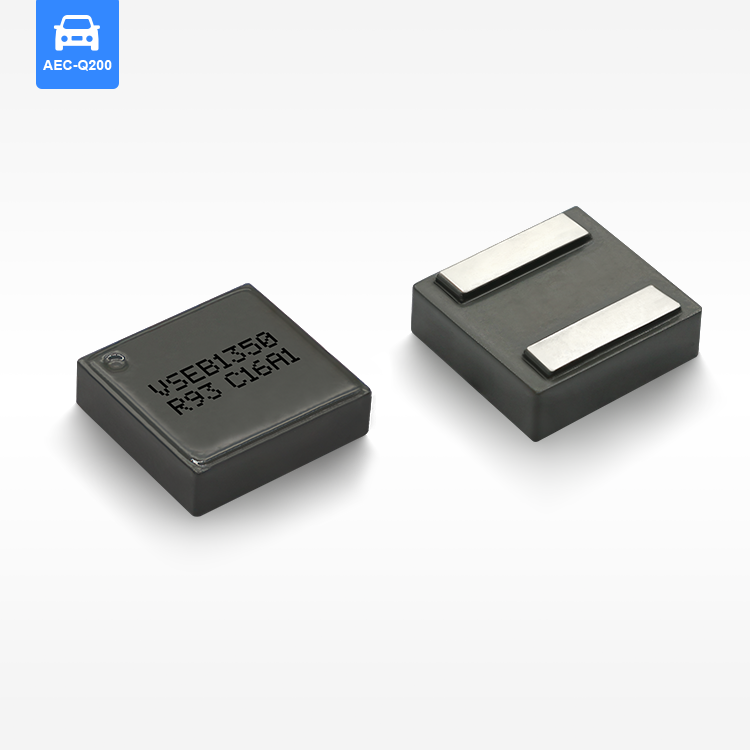

Zaawansowana Technologia Ekranowania Magnetycznego dla Doskonałej Ochrony przed EMI

Zaawansowana technologia ekranowania magnetycznego zintegrowana w wysokosprawnych induktorach ekranowanych zapewnia niezrównaną ochronę przed zakłóceniami elektromagnetycznymi, która zmienia możliwości projektowania obwodów dla inżynierów i producentów. Ten wyrafinowany system ekranowania wykorzystuje starannie dobrane materiały magnetyczne oraz konfiguracje geometryczne, które skutecznie ograniczają pole elektromagnetyczne w obrębie struktury induktora, zapobiegając niepożądanemu sprzęganiu się z sąsiednimi komponentami i obwodami. Skuteczność ekranowania przekracza zazwyczaj 40 dB w krytycznych zakresach częstotliwości, gwarantując solidną ochronę przed zakłóceniami elektromagnetycznymi, które mogłyby naruszyć wydajność systemu lub zgodność z przepisami. Ten zaawansowany mechanizm ochrony eliminuje potrzebę stosowania zewnętrznych osłon ekranujących, ferrytowych paciorków lub dodatkowych elementów filtrujących, które tradycyjnie zajmują cenne miejsce na płytce i zwiększają koszty produkcji. Technologia ekranowania magnetycznego umożliwia gęste rozmieszczenie komponentów na płytach drukowanych bez obawy o zakłócenia elektromagnetyczne między sąsiednimi induktorami lub wrażliwymi obwodami analogowymi. Inżynierowie mogą umieszczać wysokosprawne, ekranowane induktory zasilające bezpośrednio obok mikroprocesorów, obwodów radiofrecencyjnych lub urządzeń pomiarowych o dużej precyzji, nie doświadczając degradacji wydajności. Skuteczność ekranowania pozostaje stabilna mimo zmian temperatury i procesów starzenia, zapewniając niezawodną długoterminową ochronę przez cały cykl życia produktu. Ta technologia szczególnie korzystnie wpływa na aplikacje przełączane o wysokiej częstotliwości, gdzie emisja zakłóceń elektromagnetycznych bywa najczęściej problematyczna, umożliwiając projektantom stosowanie wyższych częstotliwości przełączania w celu poprawy sprawności, bez utraty zgodności elektromagnetycznej. Ograniczone pole magnetyczne redukuje również straty w pobliskich materiałach przewodzących, takich jak ścieżki miedziane, radiatory czy metalowe obudowy, co przyczynia się do ogólnych ulepszeń efektywności systemu. Klienci działający w branżach podlegających regulacjom, takich jak urządzenia medyczne, elektronika samochodowa czy zastosowania lotnicze, stwierdzają, że wysokosprawne, ekranowane induktory zasilające upraszczają zgodność ze ścisłymi normami zgodności elektromagnetycznej. Zaawansowana technologia ekranowania wspiera projekty wielowarstwowych płytek drukowanych, gdzie ograniczenia przestrzeni wymagają bliskiego sąsiedztwa obwodów konwersji mocy oraz wrażliwych ścieżek sygnałowych cyfrowych lub analogowych. Testy zapewnienia jakości potwierdzają skuteczność ekranowania poprzez rygorystyczne pomiary zgodności elektromagnetycznej, gwarantując spójną wydajność we wszystkich seriach produkcyjnych.