With the acceleration of automobile intelligence and electrification, automotive electronic systems are becoming more and more complex. From engine control units to on-board chargers, from LED drives to advanced driver assistance systems, all functions of automotive electronics are realized without the need for efficient and stable power supply. As an important component in automotive DC-DC converters, the performance of inductors determines the efficiency and stability of the entire power supply system. In order to maintain the continuous and stable operation of inductors in high power density and high current scenarios, higher requirements are put forward for high current resistance, high temperature resistance, and vibration resistance.

1- The automotive-grade high current power inductor VSRU series empower the high current application

In automotive electronics applications, the inductor is limited by the performance of the core material, the level of winding technology and the structural design. It is difficult to take into account the needs of "high current bearing, wide temperature range, excellent vibration resistance and stability". In high temperature environments, the inductance performance is easy to decrease and even cause potential safety hazards. Although some inductors have optimized heat dissipation design, the welding points are easy to loosen under the condition of severe mechanical vibration and shock, affecting the long-term reliability.

In order to solve the above problems, CODACA independently developed and designed the automotive-grade high current power inductor VSRU series. The inductors feature a flat coil winding design that provides very low DC and AC resistance. It is designed with symmetrical air gap structure to keep excellent DC bias ability. The inductance value range is 1.0~30μH, the saturation current is 10.5~100A, and the DC resistance range is 0.42~15.40mΩ.

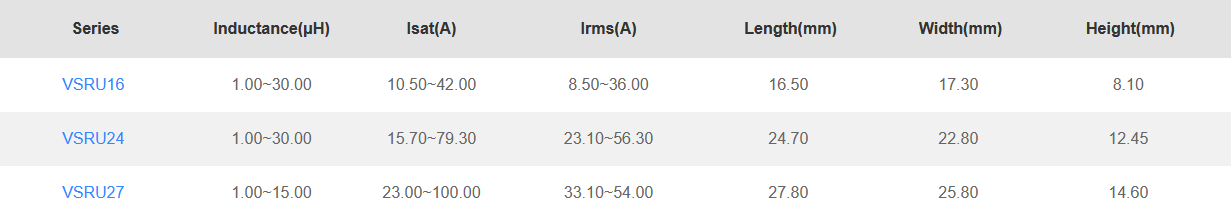

Following the launch of the VSRU27 series of automotive-grade high current power inductors, Codaca has added VSRU24 and VSRU16 series to meet the diverse needs of different customers. The minimum specification size is: 16.50*17.30*7.20mm. The compact design ensures high power density while ensuring performance, effectively saving PCB space and facilitating the integrated design of equipment. The specific specifications are shown in Table 1.

Table 1: Main specifications and dimensions of VSRU series

2- Characteristics of VSRU high-current inductor products

2.1 Symmetrical air gap structure, better DC bias ability

Automotive-grade high current power inductor VSRU series adopts an innovative symmetrical air-gapped core design, which effectively avoids magnetic saturation phenomenon and significantly improves the DC bias characteristics of the inductor. This means that the inductance value remains stable under high DC currents, ensuring that the power supply circuit can operate efficiently and stably under heavy load conditions.

VSRU27 saturation current curve

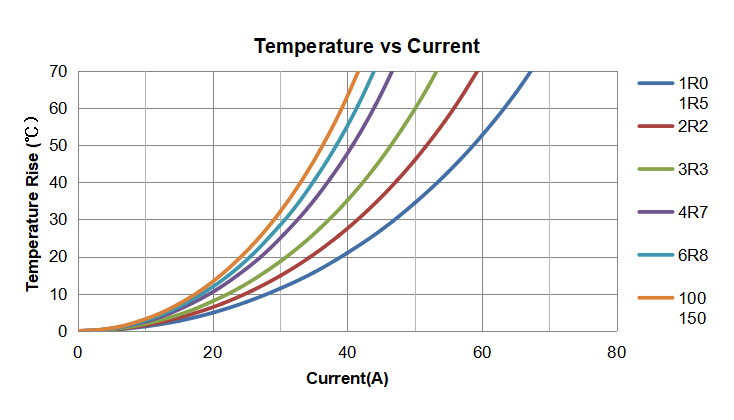

2.2 Flat wire winding, excellent heat dissipation and low temperature rise performance

Automotive-grade high current power inductor VSRU series features flat wire winding, resulting in a larger surface area and lower DC resistance compared to round wire winding. This design not only reduces copper loss and enhances overall efficiency but also greatly improves heat dissipation, resulting in lower temperature rises, ensuring long-term reliability and extended operation life of automotive electronics.

VSRU27 temperature rise current curve

2.3 Three-terminal welding structure, excellent anti-vibration performance

The innovative three-terminals structure design makes the connection between the inductor and the PCB board stronger, improve the performance in mechanical vibration test and mechanical shock test, meets the high standards in automotive applications, and ensures the firm reliability of the solder joint.

2.4 Wide working temperature range to meet the strict standards of automotive applications

Automotive-grade high current power inductors VSRU series is fully AEC-Q200 tested and has an operating temperature range from -55°C to +155°C, which can handle the challenges of extreme high and low temperature environments to meet the temperature requirements of automotive applications and other harsh industrial environments.

Codaca has a CNAS laboratory that meets the AEC-Q200 test standard and has passed the IATF16949 automotive quality system certification, providing strong support for the mass production of high-quality automotive-grade inductors.

3- Application fields

With its excellent performance and reliability, the automotive-grade high current power inductor VSRU series provides strong support for engineers when designing high-power-density, high-reliability power systems. The main areas of application are as follows:

◾ Automotive electronics: engine control units, on-board chargers, LED drivers, advanced driver assistance systems, etc., provide reliable power support for the intelligent and electrified development of automobiles.

◾ Power supply system: high-current DC-DC converter, POL (point of load) converter, high-current switching power supply to improve power conversion efficiency and ensure stable power output.

◾ Renewable energy and industrial control: photovoltaic inverters, servo drives, VRM modules and various industrial control power supplies help the development of renewable energy industries and industrial automation upgrades.

4- Environmental protection standards

The products comply with international environmental protection standards such as RoHS, REACH, and halogen-free, and practice the concept of green manufacturing.

5- Production situation

The product is in mass-production, with a delivery time of 4-6 weeks, which can also meet the needs of customers for rapid customization.

For product details, please visit the official website of Codaca or contact Codaca sales.