With the rapid development of AI technology, the number of CPU cores is increasing, and the demand for data processing is increasing exponentially. DDR5 emerged as a next-generation memory standard, aiming to meet the urgent needs of data centers, high-performance computing, and high-end computers for higher speeds and higher capacity. The transformation and development of next-generation storage technology also put forward higher requirements for the product size and electrical performance of inductors.

1- DDR5 demand for inductors

DDR5 is the abbreviation of the fifth-generation double data rate memory technology. It is a high-speed random access memory type used in computer systems to store data. Compared to DDR4 memory, DDR5 has nearly 2.5 times higher bandwidth and transfer speed, which allows DDR5 to process more data and improve system performance. The maximum capacity of DDR5 can reach or even exceed 128GB per second, making it suitable for scenarios where large memory is required, such as artificial intelligence and data centers. In addition, DDR5 requires a power conversion efficiency of more than 92% at 50% peak current load, which is higher than DDR4's 90% conversion efficiency. Overall, DDR5 has faster data transfer speeds, lower power consumption, higher efficiency conversion requirements, and larger memory capacity.

Unlike DDR4, which places the main power management chip on the motherboard, DDR5 memory modules integrate the power management IC. It is this architectural change that changes the role and performance requirements of the inductor. The main requirements for inductors are as follows:

◾ Higher operating frequency: DDR5 PMICs use a switching power supply architecture that switches at higher frequencies (above 1MHz) for higher conversion efficiency and faster transient response. Inductors need to have high frequency characteristics to maintain stable magnetic characteristics in high-frequency applications, i.e., low core loss.

◾ Higher conversion efficiency and lower loss: DDR5 has a power conversion efficiency higher than 92%, requiring inductors to have lower DC resistance and lower core losses. Under high-frequency switching, the hysteresis and eddy current losses of the core must be minimized.

◾ Higher Saturation Current: DDR5 memory particles operate at lower voltages but process more data and at higher speeds, resulting in high and fluctuating instantaneous peak currents. Excellent saturation current characteristics allow inductors to handle instantaneous high peak currents without inductor failure.

◾ Smaller size, higher power density: DDR5 PMICs and their surrounding passive components are directly integrated into the memory modules, and PCB board space is extremely limited. And there is a multiphase power supply on each memory module, which requires multiple inductors, which promotes the development of inductors towards miniaturization, thinness, and high power density.

2- Small-size molded power inductors are recommended

In order to meet the needs of end customers for DDR5 inductors, Codaca has launched a series of small-size, high-efficiency and low-loss inductors through independent research and development and technological innovation. Among them, the KSTB and CSTB series molded inductors are specially designed to meet the strict requirements of DDR5. The inductors are optimized for high current capacity, low loss characteristics, high reliability and compact layout, making them ideal for modern DDR5 memory modules.

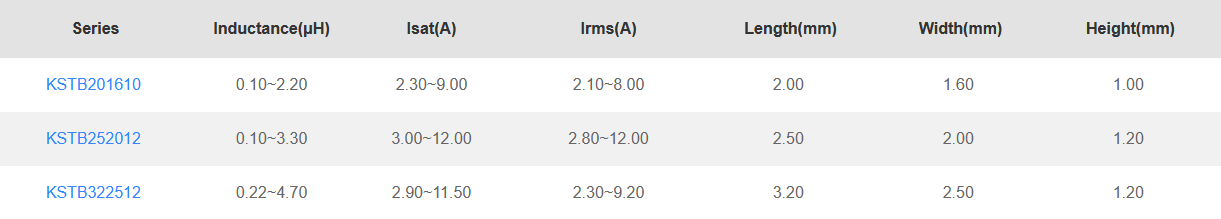

2.1 Molded power inductor KSTB series

KSTB molded power inductors currently have three series, named KSTB201610, KSTB252012, and KSTB322512. Among them, the KSTB201610 series inductors have a size of only 2.0mm x 1.6mm x 1.0mm. KSTB series inductors are molded with flat wire winding and metal magnetic powder core material, which has the characteristics of low loss, high efficiency, and wide application frequency, with an inductance value range of 0.10~4.70μH, a saturation current of 2.30~12.00 A, and a DC resistance value range of 4.0~115 mΩ.

Table 1: Main specifications and dimensions of KSTB series inductors

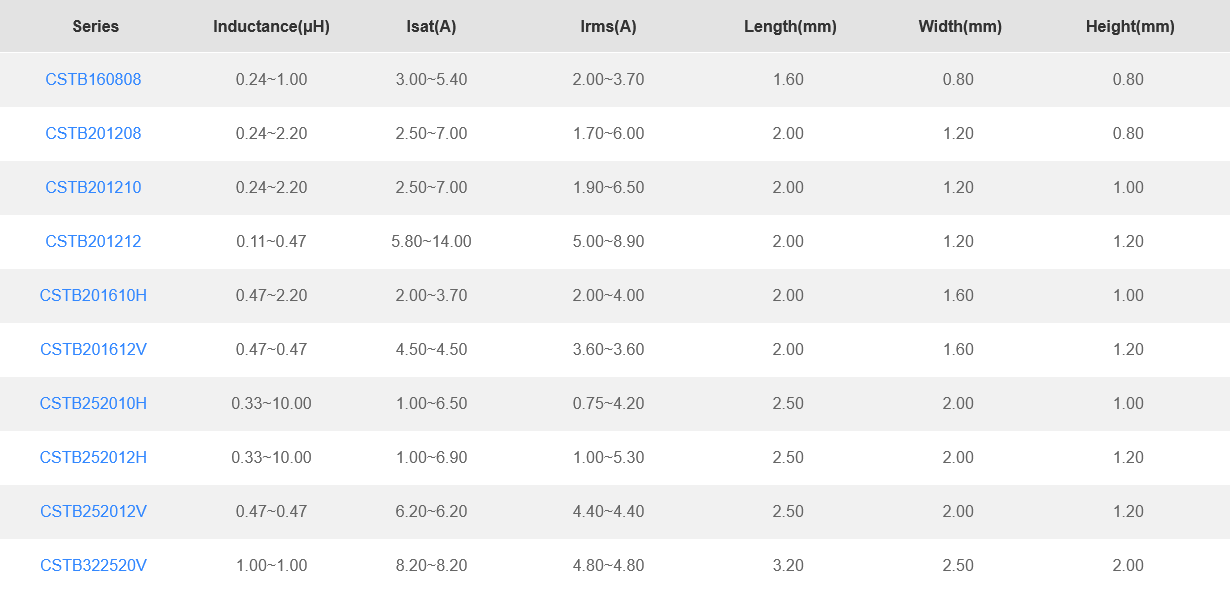

2.2 Molding power chokes CSTB series

CSTB series molding power chokes are currently available in 10 series, with a minimum size of 1.6mm x 0.8mm x 0.8mm. This series of inductors is made of low-loss alloy powder, which has excellent performance such as low loss, high efficiency, and wide application frequency. The thin and light design saves space and is suitable for high-density mounting. The inductance value range is 0.11~10.0 μH, the saturation current is 1.0~14.0 A, and the minimum resistance value is 7.0 mΩ.

Table 2: Main specifications and dimensions of CSTB series inductors

3- Product features

The KSTB and CSTB series of small-sized molded inductors from Codaca have been comprehensively optimized in terms of structure, materials, and processes to meet the high requirements for inductor product size and electrical performance in high-power density design schemes such as DDR5. Its main characteristics are as follows:

3.1 Molded structure, ultra-low noise

The molded structure design effectively suppresses the vibration noise caused by the gap between the core and the coil or magnetostriction of the traditional inductor, and achieves ultra-low noise. This is key to improving the user experience for servers, storage devices, and consumer electronics that require a quiet operating environment.

3.2 High efficiency, low loss, excellent high-frequency performance

The inductors feature flat coil windings and low-loss magnetic powder technology with very low direct current resistance (DCR) and core loss. At the same time, the inductor has high frequency characteristics and maintains high efficiency over a wide frequency range, making it particularly suitable for high-frequency switching power supply applications, significantly reducing the overall energy consumption and temperature rise of the system.

3.3 Thin and compact, saving space

The size of the molded inductor adopts a thin and light design, with the minimum size of KSTB series inductors being 2.0 x 1.6 x 1.0 mm, and CSTB series inductors having a minimum size of 1.6 x 0.8 x 0.8mm, allowing DDR5 to achieve high-density mounting in a compact space and providing flexibility for complex circuit designs.

3.4 Magnetic shielded structure, strong anti-electromagnetic interference performance

Magnetic shielded structure is designed for strong electromagnetic interference (EMI) resistance. It helps products easily pass EMC tests and improve the operational stability of the entire system.

3.5 Adapt to harsh environments, stable and reliable products

Operating temperature range: -40 / -55°C ~ +125°C, it can work well under various harsh working environments, ensuring stable electrical performance even under a wide range of temperature conditions.

4- Application fields

With their thin and lightweight design and excellent electrical performance, the CSTB and KSTB series of small-sized molded power inductors help achieve high energy efficiency in power conversion, making them ideal for engineers to balance performance, space, and cost in next-generation computing systems. Its main applications are as follows:

◾ DDR5, solid state drives

◾ CPU/GPU processors

◾ Noise suppression and filtering circuits

◾ Network communication and data storage systems

5- Production situation

The product has been mass-produced with a lead time of 4-6 weeks.

The products comply with RoHS, REACH, halogen-free and other environmental protection requirements.

For product details, please visit the official website of Codaca or contact Codaca sales.