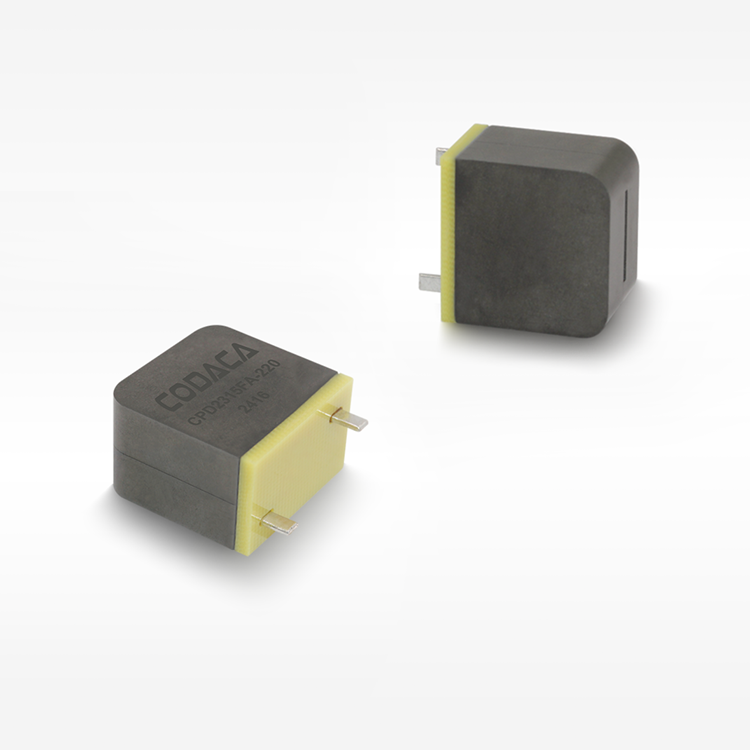

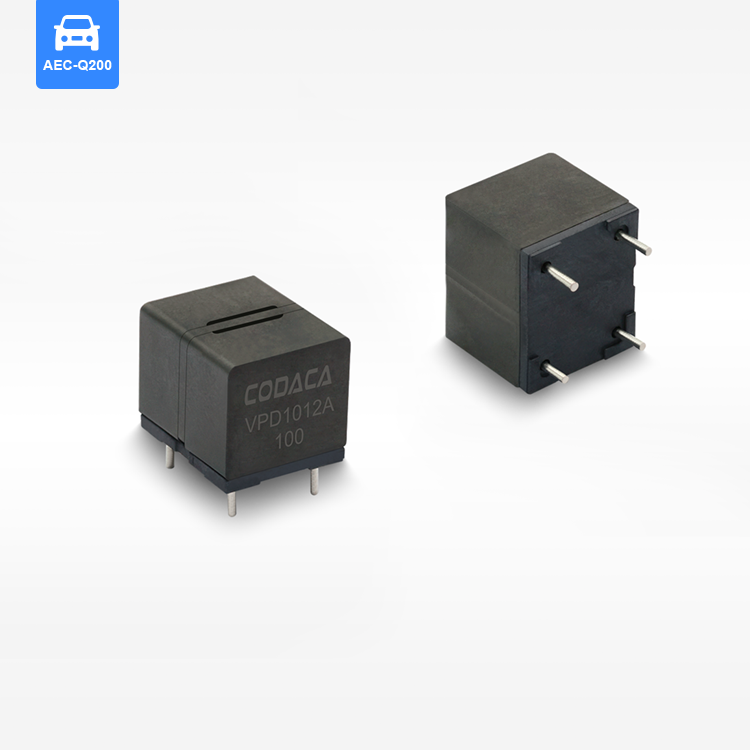

high current ferrite inductor

The high current ferrite inductor represents a critical electronic component engineered to handle substantial electrical currents while maintaining exceptional performance characteristics. This specialized inductor utilizes ferrite core materials, which are ceramic compounds made from iron oxide combined with other metallic elements, creating a magnetic core that offers superior electromagnetic properties. The primary function of a high current ferrite inductor involves storing energy in its magnetic field when current flows through its windings, then releasing this energy when the current changes direction or magnitude. This fundamental operation makes it indispensable in power management applications where current regulation and filtering are essential. Technologically, the high current ferrite inductor incorporates advanced design features that distinguish it from conventional inductors. The ferrite core material exhibits high magnetic permeability, allowing the component to achieve substantial inductance values in compact form factors. The core's composition provides excellent frequency response characteristics, making these inductors particularly effective in switching power supplies and high-frequency applications. Manufacturing processes involve precision winding techniques using high-grade copper wire, ensuring minimal resistance and optimal current-carrying capacity. The core geometry is carefully engineered to prevent magnetic saturation even under heavy current loads, maintaining stable inductance values across varying operational conditions. Applications for high current ferrite inductors span numerous industries and electronic systems. Power supply circuits extensively utilize these components for output filtering, energy storage, and current smoothing in both AC-DC and DC-DC converter topologies. Automotive electronics incorporate high current ferrite inductors in electric vehicle charging systems, motor drive circuits, and power distribution networks. Renewable energy systems, including solar inverters and wind power converters, depend on these inductors for efficient power conversion and grid synchronization. Industrial automation equipment, telecommunications infrastructure, and consumer electronics also benefit from the reliable performance characteristics that high current ferrite inductors provide in demanding operational environments.