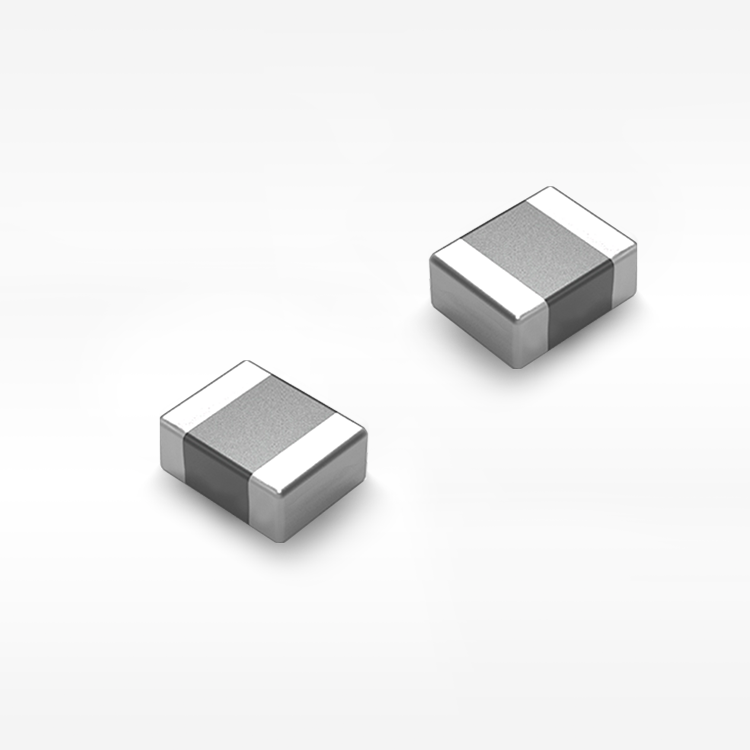

shielded high current power inductor

The shielded high current power inductor represents a critical component in modern power management systems, designed to handle substantial electrical loads while maintaining optimal performance and electromagnetic compatibility. This sophisticated electronic component combines advanced magnetic core technology with precision-engineered shielding to deliver superior inductance characteristics in high-power applications. The primary function of a shielded high current power inductor centers on energy storage and release within electrical circuits, particularly in switching power supplies, DC-DC converters, and motor drive systems where substantial current flow demands robust component performance. The technological foundation of these inductors relies on carefully selected magnetic materials, typically ferrite or powdered iron cores, which provide excellent magnetic permeability while minimizing core losses at elevated current levels. The shielding mechanism, often implemented through magnetic shielding materials or closed-core designs, effectively contains electromagnetic fields, preventing interference with nearby sensitive components and ensuring regulatory compliance with electromagnetic compatibility standards. Modern manufacturing techniques enable precise control of inductance values, current ratings, and thermal characteristics, allowing engineers to select components that match specific application requirements. The physical construction incorporates heavy-gauge wire windings capable of carrying substantial current without excessive heating, while the core geometry optimizes magnetic flux distribution for consistent performance across varying load conditions. Temperature stability represents another crucial technological feature, with specialized core materials and construction methods ensuring minimal inductance drift across wide operating temperature ranges. These inductors find extensive applications in automotive electronics, renewable energy systems, industrial automation equipment, and telecommunications infrastructure where reliable power conversion and filtering capabilities are essential. The combination of high current handling capability, electromagnetic shielding, and thermal stability makes the shielded high current power inductor an indispensable component in demanding power electronic applications.