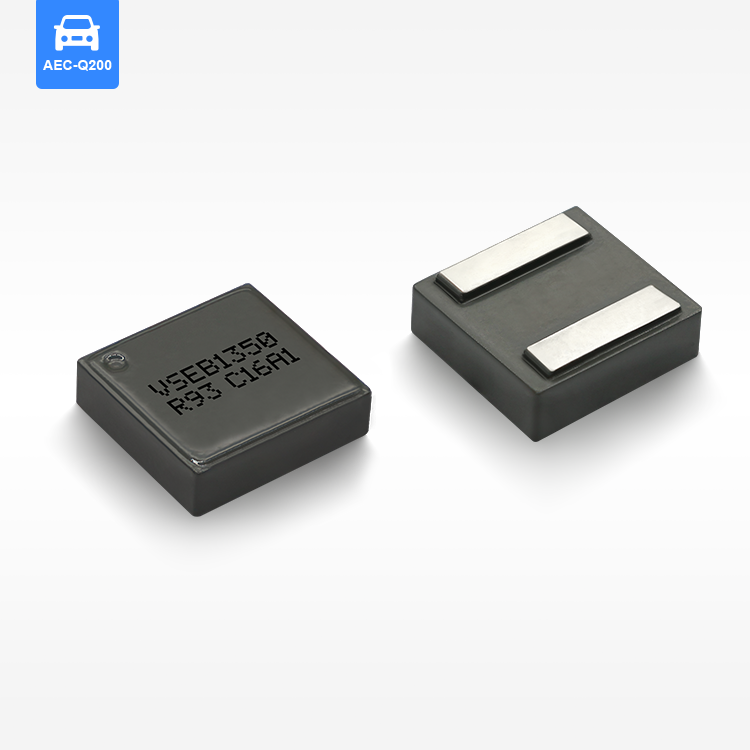

high current shielded power inductor manufacturer

A high current shielded power inductor manufacturer stands as a cornerstone in the modern electronics industry, producing specialized magnetic components that serve critical functions in power management systems. These manufacturers design and produce inductors capable of handling substantial electrical currents while maintaining electromagnetic interference shielding through integrated magnetic cores and specialized housing designs. The primary function of these components involves energy storage in magnetic fields, current filtering, and voltage regulation across various electronic applications. High current shielded power inductor manufacturers employ advanced ferrite core technologies, precision winding techniques, and innovative shielding methodologies to create components that excel in demanding environments. The technological features encompass low DC resistance characteristics, high saturation current ratings, excellent thermal performance, and compact form factors that optimize board space utilization. These manufacturers utilize sophisticated manufacturing processes including automated winding systems, precision core assembly, and comprehensive testing protocols to ensure consistent product quality. The magnetic shielding technology prevents electromagnetic interference between adjacent components, making these inductors ideal for dense circuit board layouts. Applications span across automotive electronics, telecommunications infrastructure, renewable energy systems, industrial automation equipment, and consumer electronics. In automotive applications, these inductors support electric vehicle charging systems, engine management modules, and advanced driver assistance systems. Telecommunications equipment relies on these components for base station power supplies, network switching hardware, and signal processing units. Industrial applications include motor drives, welding equipment, power conversion systems, and factory automation controllers. The manufacturing process involves careful selection of core materials, precise wire gauge selection, and specialized assembly techniques that ensure optimal electrical and magnetic performance. Quality control measures include inductance testing, current handling verification, and electromagnetic compatibility assessment to meet stringent industry standards and customer requirements.