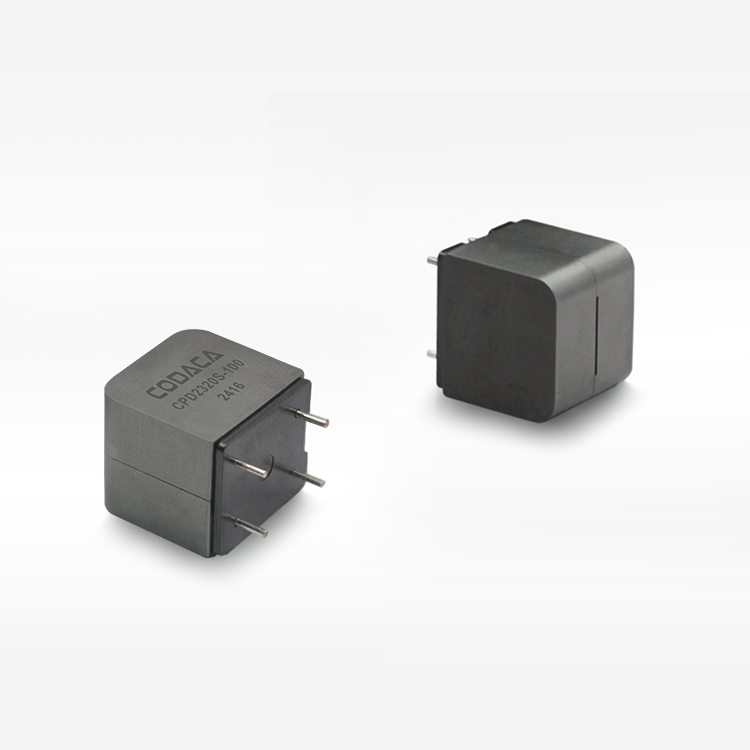

low dcr high current shielded inductor

The low dcr high current shielded inductor represents a crucial component in modern electronic circuits, designed to provide superior performance in power management applications. This specialized inductor combines three essential characteristics that make it invaluable for demanding electronic systems. The low DCR (Direct Current Resistance) feature minimizes power losses during operation, ensuring efficient energy transfer throughout the circuit. Meanwhile, the high current capability allows these inductors to handle substantial electrical loads without compromising performance or reliability. The shielded design provides electromagnetic interference protection, preventing unwanted interactions with nearby components and maintaining signal integrity. These inductors serve multiple functions within electronic systems, primarily focusing on energy storage, current filtering, and voltage regulation. They effectively smooth out current fluctuations in power supplies, reducing ripple and maintaining stable output voltages. The magnetic shielding surrounding the inductor core contains the magnetic field, preventing electromagnetic interference that could disrupt sensitive nearby components. This containment also reduces the inductor's overall footprint while maintaining optimal performance characteristics. Technologically, these inductors incorporate advanced core materials and winding techniques to achieve their superior specifications. The core typically utilizes high-permeability ferrite or powder materials that enhance inductance while minimizing losses. Precision winding methods ensure uniform current distribution and optimal magnetic field characteristics. Applications for low dcr high current shielded inductors span across numerous industries and electronic devices. They are essential in switching power supplies, DC-DC converters, automotive electronics, telecommunications equipment, and industrial automation systems. Computer processors, graphics cards, and mobile devices rely on these inductors for stable power delivery. The automotive industry increasingly depends on these components for electric vehicle charging systems, motor controllers, and advanced driver assistance systems. Their robust construction and reliable performance make them suitable for harsh environmental conditions while maintaining consistent electrical characteristics across wide temperature ranges.