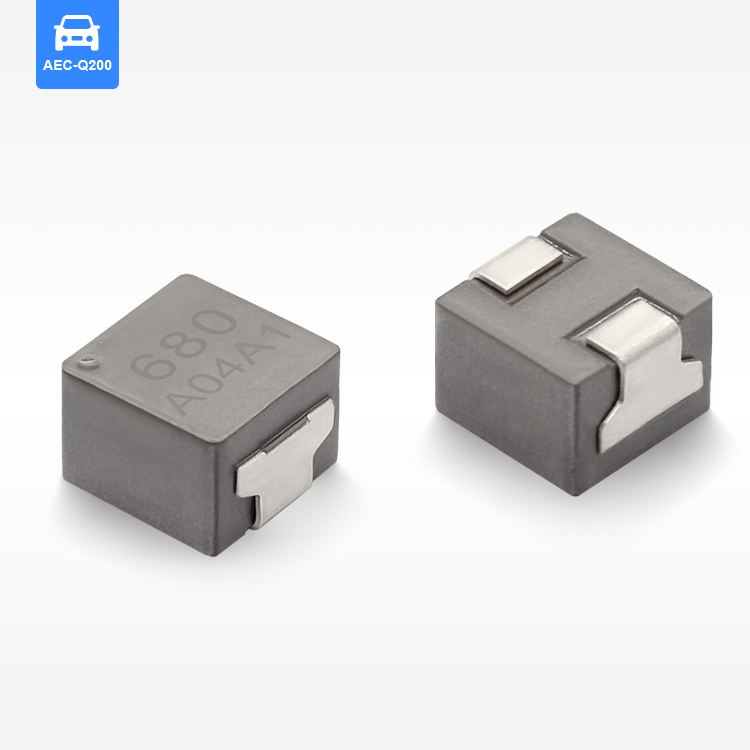

high current magnetic component manufacturer

A high current magnetic component manufacturer specializes in designing, developing, and producing advanced magnetic components capable of handling substantial electrical currents while maintaining optimal performance and reliability. These specialized manufacturers focus on creating transformers, inductors, chokes, and custom magnetic assemblies that serve critical roles in power electronics, renewable energy systems, electric vehicles, industrial automation, and telecommunications infrastructure. The primary function of a high current magnetic component manufacturer involves engineering magnetic cores, windings, and complete assemblies that can efficiently manage high-power applications without compromising safety or performance standards. These companies utilize advanced materials such as ferrite cores, powdered iron, amorphous metals, and nanocrystalline alloys to achieve superior magnetic properties and thermal management capabilities. The technological features that distinguish a leading high current magnetic component manufacturer include precision winding techniques, automated manufacturing processes, comprehensive testing protocols, and innovative cooling solutions. These manufacturers employ sophisticated simulation software and modeling tools to optimize magnetic field distribution, minimize losses, and ensure consistent performance across varying operating conditions. Quality control measures encompass rigorous testing for electrical characteristics, thermal performance, mechanical durability, and environmental resistance. Applications for products from a high current magnetic component manufacturer span numerous industries including renewable energy systems where they enable efficient power conversion in solar inverters and wind turbine generators. Electric vehicle charging infrastructure relies heavily on these components for safe and efficient power delivery. Industrial motor drives, welding equipment, uninterruptible power supplies, and medical imaging systems all depend on high-quality magnetic components. The manufacturing process involves careful selection of core materials, precise winding configurations, appropriate insulation systems, and robust encapsulation techniques. A reputable high current magnetic component manufacturer maintains strict adherence to international standards and certifications, ensuring products meet safety requirements and performance specifications demanded by modern applications.